Door manufacturers are using DriveWorks to optimize their sales & manufacturing processes.

Digital technologies are enabling manufacturers to design quicker, communicate better, and transform the customer experience.

Read about how door manufacturers are using DriveWorks software to save time and reduce errors.

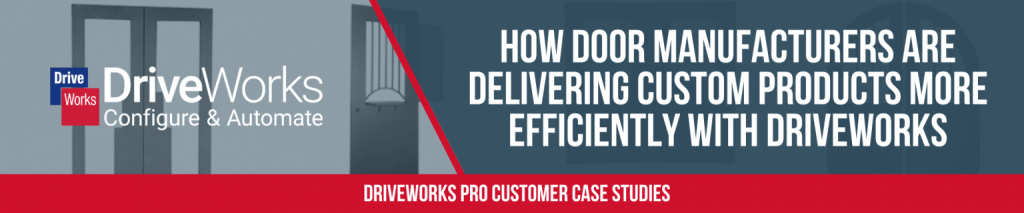

Eurobond Doors

Eurobond Doors, headquartered in Wales, UK, manufactures design-to-order industrial and commercial steel doors. As a customer-driven business, Eurobond Doors wants to ensure that its customer base has the best possible experience, which means shorter lead times and increased efficiency and consistency.

Eurobond Doors’ product offering consists of 83 configurable parts. The DriveWorks configurator allows them to easily enter the door specification as detailed in their job traveler. This can be done manually, or directly from an XML generated by their ERP system.

Working together, DriveWorks Autopilot and SOLIDWORKS then generate the required models and manufacturing drawings automatically, ready for checking by the engineering team.

When a customer approves a quote, the salesperson can go back into the system, pick up the quote drawing, and produce the shop drawing automatically, along with the BOM – all through DriveWorks.

DriveWorks is helping Eurobond to work more efficiently and their DriveWorks project is easy to maintain.

“For us, the most important thing about DriveWorks is our improved efficiency, and reduced costly data entry errors”

Anthony Coombes, Design Manager, Eurobond Doors

Learn more about how Eurobond Doors are reducing reducing costly design errors with DriveWorks Pro:

JELD-WEN

JELD-WEN manufactures a wide range of high-quality timber doors for the construction and renovation markets around the world.

The speed at which JELD-WEN creates new product configurations is now much faster, thanks to DriveWorks.

DriveWorks covers 75-80% of customer orders for special cut-outs for doors and complete glass panels. JELD-WEN has over 25,000 drawings in DriveWorks that form the basis for the development of new products.

This makes the development of new products much faster and customers receive drawings of their custom product drawings quicker. Drawings are received and sent to customers within minutes with DriveWorks.

The benefits of DriveWorks go further than engineering. DriveWorks is helping sales team members to communicate with customers more effectively, delivering drawings of their custom products to customers.

Previously, it could take up to 3 days for JELD-WEN to make the drawings available for the customer.

Now, drawings are received by a salesperson in as little as 5 – 10 minutes. The drawing is forwarded directly to clients for final review before manufacturing.

Learn more about how JELD-WEN are saving engineering time and improving customer experience with DriveWorks Pro:

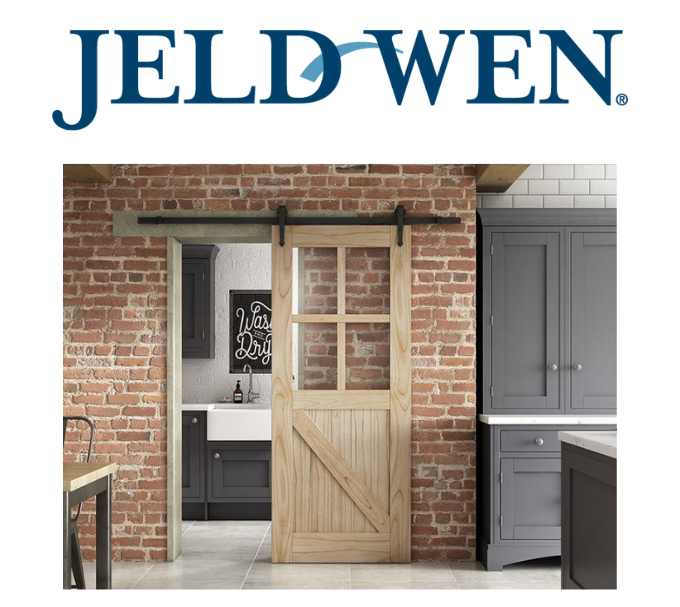

Karpen Steel

Karpen Steel, based in the USA, manufactures high-quality custom doors and frames. They aim to exceed customer expectations by manufacturing dependable products that meet critical quality standards with prompt, on-time delivery.

Using DriveWorks Pro, Karpen Steel has streamlined its order process. The amount of employee time needed to process each order has been reduced and the process is now slicker and more efficient, allowing Karpen Steel to concentrate on winning more orders and providing great customer service.

Once an order is received, the customer service team enters the parameters of the order into the DriveWorks Configurator. This then creates the 3D SOLIDWORKS model and order documents for both the customer and the workshop. The price for the order is also generated and the order or quote is placed as a database entry. This is all done in one single step with DriveWorks.

The form within the DriveWorks Pro Configurator guides a user through the order process. Customers can only see, and are prompted to fill out, the relevant fields on the form for the product line they have selected. By using pictures, pop-up warnings, and instructions, errors are highlighted before the order progresses to the next step. The ability to set up error checking within DriveWorks Pro prevents the user from leaving out required information or entering parameters that can’t be manufactured. This helps to minimize the number of times orders must be returned due to incomplete or inaccurate information, which would disrupt the order flow.

As DriveWorks automates SOLIDWORKS, the customer service team are effectively now using its powerful 3D capabilities, without the need for any SOLIDWORKS training. Karpen Steel’s engineering team are freed up from simple, repetitive tasks to focus on the more critical aspects of the order.

A process that previously required 4 team members is now automated and streamlined.

Learn more about how Karpen Steel are streamlining their order process with DriveWorks Pro:

Online Configurator Examples

Our product configurator examples are a great way to see what’s possible with DriveWorks, in a range of scenarios and industries.

DriveWorks product configurator software is used by companies of all sizes. It’s suitable for any industry where quotes or 3D files and drawings are part of the sales to the manufacturing process.

Our configurator examples show how versatile and customizable DriveWorks is and provide great inspiration for your DriveWorks projects.

The software is not limited to what you see in our examples, with DriveWorks you build a custom solution that suits your needs and is easy to maintain and update.

Explore our online configurator examples to see how versatile and easy to use DriveWorks is.

Try DriveWorks

Follow the 3 easy steps below to download the DriveWorks Solo 30 Day Free Trial and get started.

Join the DriveWorks Community

Download and Licence DriveWorks Solo

Automate SOLIDWORKS®