Industry Spotlight

HVAC

Overcoming industry challenges

HVAC manufacturers are using DriveWorks design automation & sales configurator software to improve manufacturing and sales processes and be more efficient.

Technological advancements

Rapid technological advancements, including the integration of smart and connected technologies, require HVAC manufacturers to continually update their products. Keeping pace with innovation while maintaining cost-effectiveness is a challenge.

Sales teams need to easily access updated product information to enable them to sell the best product solution without having to refer to multiple information sources.

How DriveWorks helps

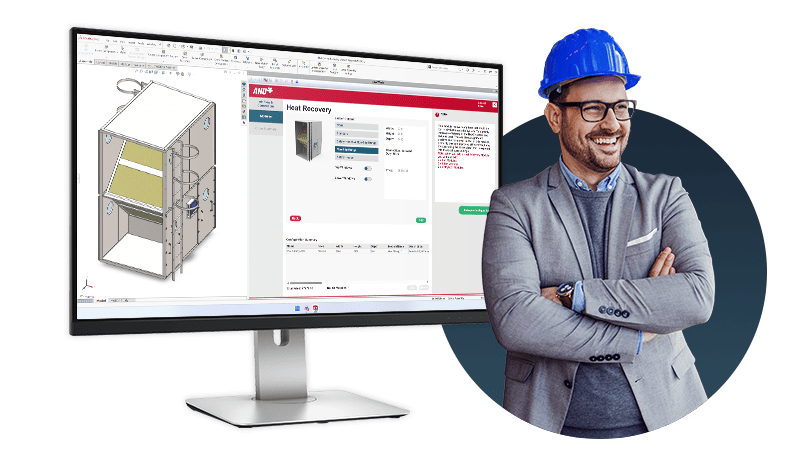

CPQ and guided selling tools in DriveWorks enable sales teams to access the latest configurable product solutions. Accurate information about new product options helps salespeople sell confidently.

Engineering teams are freed up to work on higher-value projects because design automation handles the majority of the “same but different” design work.

DriveWorks’ design automation capabilities enable HVAC manufacturers to integrate the latest technologies seamlessly. It allows for the quick adoption of new features and improvements without requiring extensive manual redesign. This ensures that HVAC systems stay technologically competitive.

Supply chain management

The HVAC industry, like many others, can be affected by disruptions in the global supply chain. Events such as natural disasters, geopolitical issues, or health crises can impact the availability of raw materials and components.

How DriveWorks helps

DriveWorks enables agile and flexible HVAC manufacturing. In case of supply chain disruptions, manufacturers can easily reconfigure HVAC designs to accommodate alternative components or suppliers. This adaptability helps mitigate the impact of disruptions on production.

Skilled labor shortage

The HVAC industry relies on skilled technicians and engineers. There is a growing concern about a shortage of skilled labor, and manufacturers face challenges in recruiting and retaining qualified personnel.

How DriveWorks helps

DriveWorks reduces the dependency on highly skilled designers and engineers by automating repetitive design tasks.

This not only addresses the shortage of skilled labor but also allows existing teams to focus on more complex and strategic aspects of HVAC product development.

Market saturation

In mature markets, the HVAC industry may face saturation, making it challenging for companies to differentiate their products. Manufacturers must focus on innovation and unique value propositions to stand out.

How DriveWorks helps

DriveWorks CPQ solution enables HVAC manufacturers to offer a wide range of customizable HVAC products. Sales teams can use the software to quickly configure and visualize different HVAC product options, helping customers see the unique value propositions and differentiate offerings in a saturated HVAC market.

Consumer education

Educating consumers about the benefits of energy-efficient HVAC systems and smart technologies can be a challenge. Many consumers may not be fully aware of the long-term cost savings and environmental benefits associated with modern HVAC systems.

How DriveWorks helps

DriveWorks calculates pricing in real time as products are configured and the powerful rules engine can be used to calculate savings.

DriveWorks enables the creation of interactive and visual configurations. Sales teams can use these configurations to educate consumers about the benefits of energy-efficient and technologically advanced HVAC systems. Visualization tools help customers understand the value they get from different HVAC product features.

Regulatory compliance

Keeping up with and adhering to changing environmental regulations and building codes can be complex. HVAC manufacturers and sales teams must navigate compliance requirements, which may vary across regions.

How DriveWorks helps

DriveWorks can be configured to ensure that HVAC designs automatically comply with the latest regulatory standards. This reduces the risk of non-compliance and streamlines the process of adapting to changing regulations, ensuring that HVAC products meet the necessary certifications.

Sales teams are enabled to sell confidently, knowing that product configurations are valid.

Seasonal demand fluctuations

Demand for HVAC products tends to be seasonal, with peaks during extreme weather conditions. HVAC companies must manage inventory, production, and staffing to accommodate these fluctuations.

How DriveWorks helps

DriveWorks’ automation capabilities allow for efficient management of seasonal demand fluctuations. HVAC manufacturers can adjust production schedules, optimize inventory levels, and quickly respond to shifts in market demand by automating the configuration and quoting processes.

Customer Success Story

HW Ventilation

Learn how HW Ventilation have achieved 10x faster design times using DriveWorks Solo.

Get started with DriveWorks

Getting started with DriveWorks is quick and easy.

Get started for free

DriveWorksXpress is free inside SOLIDWORKS and you can try DriveWorks Solo free for 30 days.

Explore solutions

Learn more about how the features in DriveWorks can be utilized.

Compare software

Compare the features in DriveWorksXpress, DriveWorks Solo, and DriveWorks Pro.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.