Configure, design, sell, and manufacture custom products faster

DriveWorks technology enables you to accurately configure custom products, calculate pricing, and automatically create documents and data for sales and manufacturing.

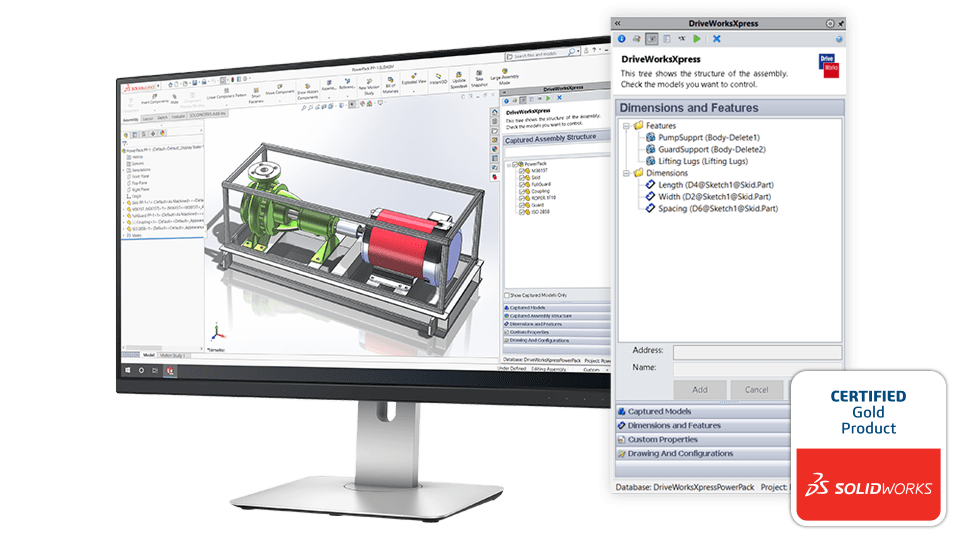

Automate SOLIDWORKS®

Automatically create order-specific SOLIDWORKS® parts, assemblies, and drawings.

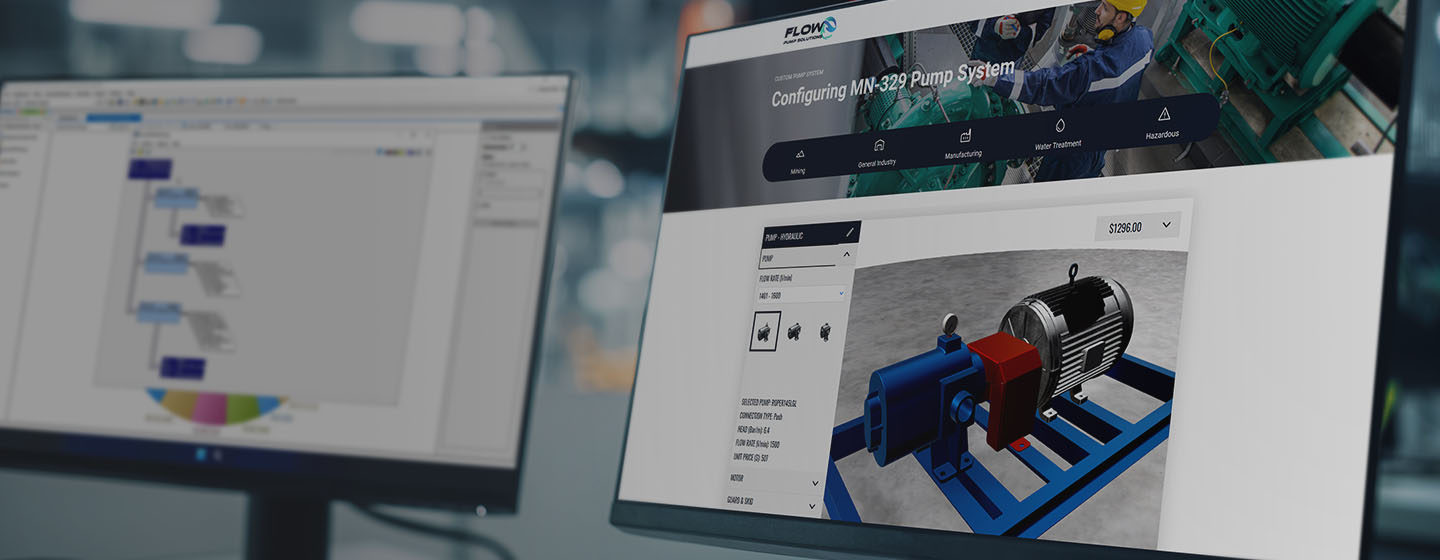

3D Product Configurator

Use guided selling and 3D visualizations to help users configure complex custom products accurately.

Configure, Price, Quote (CPQ)

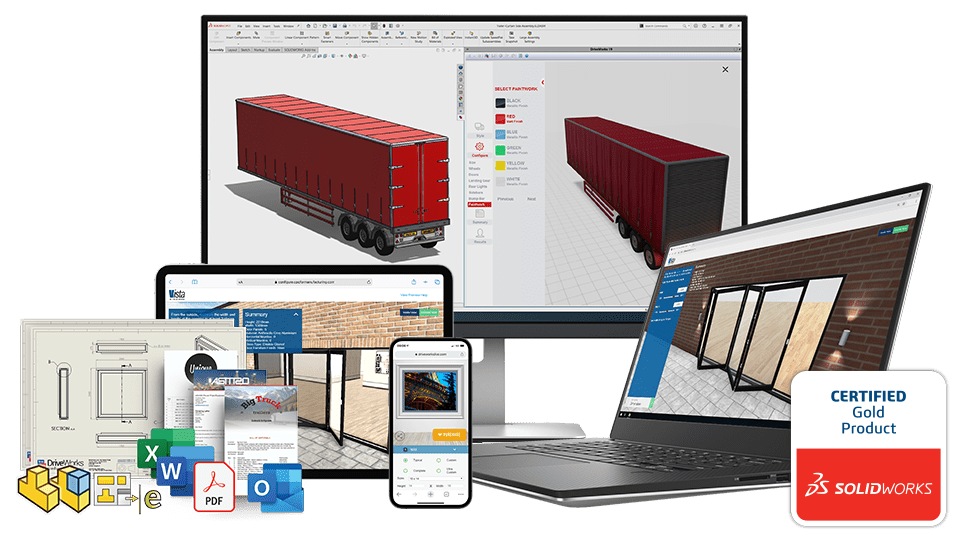

Configure, price, and quote complex custom products on any device, anywhere.

Try DriveWorks Solo free for 30 days, instant access, and no credit card required.

What is DriveWorks?

Use DriveWorks to build your own design automation, 3D product configurator and CPQ for Manufacturing solution.

Enable your engineers, sales teams, dealers and distributors, to design, engineer, and configure to order, on premise or online.

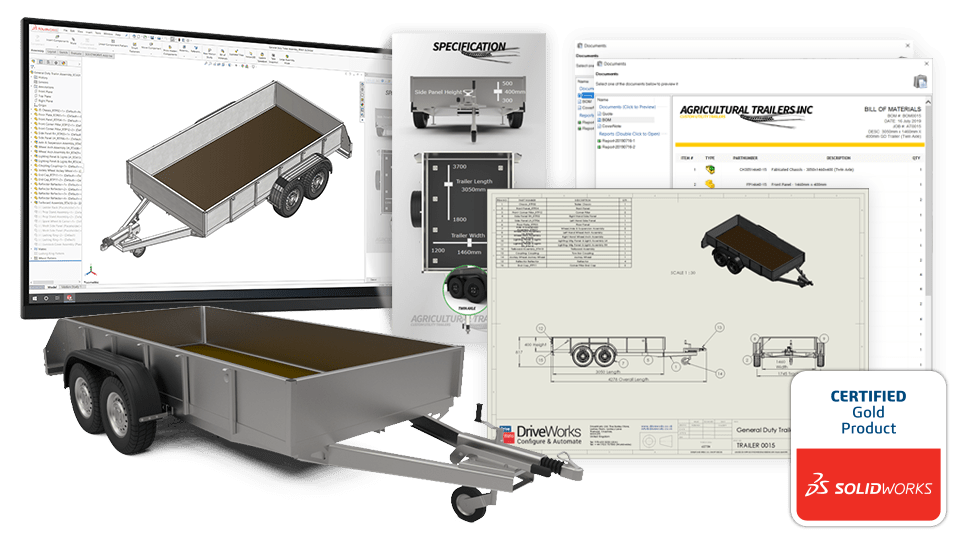

Automate the creation of order-specific quotes, sales documents and associated SOLIDWORKS® manufacturing data.

Reduce repetitive tasks, eliminate errors, increase sales, and deliver custom products in record time.

Features & benefits

DriveWorks configurator software is the ultimate choice in SOLIDWORKS® design automation and 3D CPQ for manufacturing.

Boost quality

DriveWorks product configurators are based on rules, calculations and logic, improving the quality of outputs, reducing costly errors and strengthening your reputation.

Respond faster, sell more

Impress your customers and win more orders by responding quicker than your competitors. Automatically generate accurate quotes, engineering drawings, and manufacturing data.

Any device, anywhere

Enable customers, sales teams, and distributors to configure, price, and quote on any device, anywhere. Communicate design details with interactive 3D visualizations.

Faster implementation

Your team knows your products best. DriveWorks configurators are easy to set up in-house with no programming skills or consultants required.

“It’s a huge advantage if you can manage design, configuration, automation, and sales in one application”

Thorsten Winkelmann, Area Sales Manager at ERHARDT Markisenbau GmbH

Try DriveWorks for free

Get instant access to DriveWorks Solo for 30 days, no credit card required.

Software

SOLIDWORKS® design automation and product configurator software.

How to buy DriveWorks software

DriveWorks is sold worldwide and supported locally by authorized and certified DriveWorks resellers, in your time zone.