ERHARDT Markisenbau

DriveWorks Design Automation and CPQ for Manufacturing has enabled ERHARDT to keep pace with increasing demand while maintaining their reputation for high-quality products

Challenge

ERHARDT needed a solution to streamline sales, reduce errors and optimize engineering and manufacturing processes.

Solution

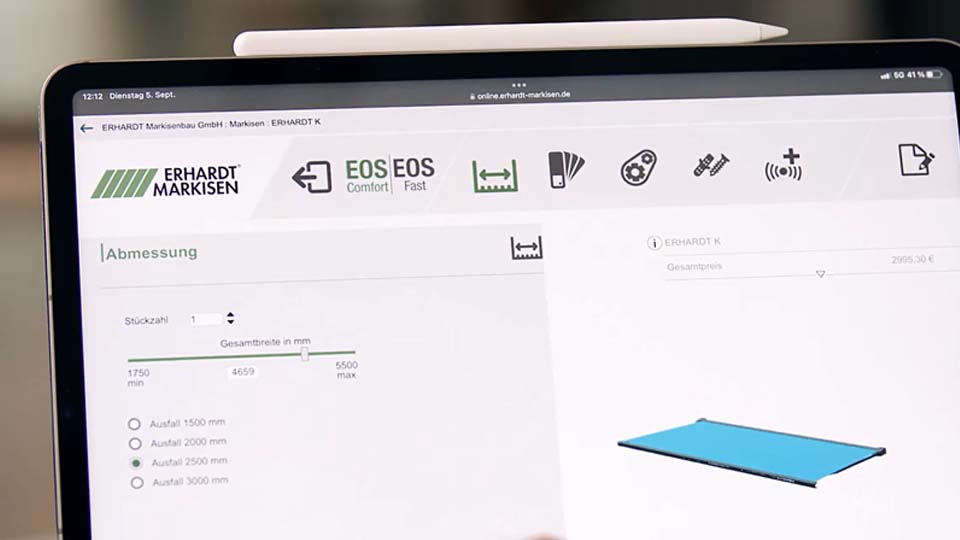

DriveWorks CPQ for Manufacturing connects sales and manufacturing, ensuring distributors have the information they need to configure products accurately. Direct ERP integration ensures distributors always have the latest pricing and product information while 3D visualizations help customers see their product choices in real-time.

Results

DriveWorks has enabled ERHARDT to manufacture products configured by the retailer without further modification by the design department. Processes have been optimised and error rates are considerably lower. DriveWorks has become an integral part of ERHARDT’s processes.

Company overview

ERHARDT manufactures high-quality, customized products for sun protection, outdoor living, and terrace roofs. Their products are manufactured to the highest standards at their headquarters in Germany and distributed worldwide. Since being founded in 1980, ERHARDT have grown to around 250 employees.

DriveWorks has massively improved our workflow in the whole company. We would never like to work without DriveWorks.

Thorsten Winkelmann, Area Sales Manager – ERHARDT Markisenbau GmbH

Challenge

ERHARDT identified the need for an automated solution that could optimize the sales process, reduce error rates, and allow custom products to be delivered efficiently.

Producing in large quantities while maintaining very high-quality standards presented ERHARDT with key challenges:

- Streamline the sales process for distributors and internal sales

- Enable distributors to provide accurate pricing as the customer configures options

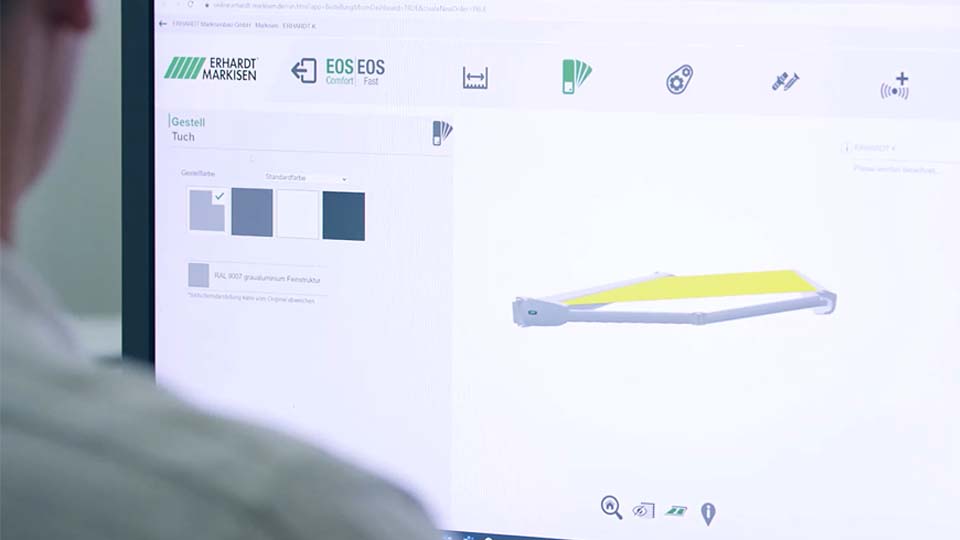

- Help customers visualize their product choices

- Improve manufacturing efficiency and reduce error rates

- The manufacturing team needed a tool to reduce repetitive design work to increase throughput

- Reduce error rates to ensure products meet strict quality standards

- Ensure manufacturing is efficient and accurate

Solution

The obvious choice for SOLIDWORKS®

ERHARDT had already implemented SOLIDWORKS in their engineering department, so DriveWorks Design Automation and CPQ for Manufacturing was the obvious choice. The unique combination of CPQ and SOLIDWORKS design automation was the key factor for ERHARDT choosing DriveWorks.

“It’s a huge advantage if you can manage design, configuration, automation, and sales in one application” – Thorsten Winkelmann, Area Sales Manager at ERHARDT Markisenbau GmbH.

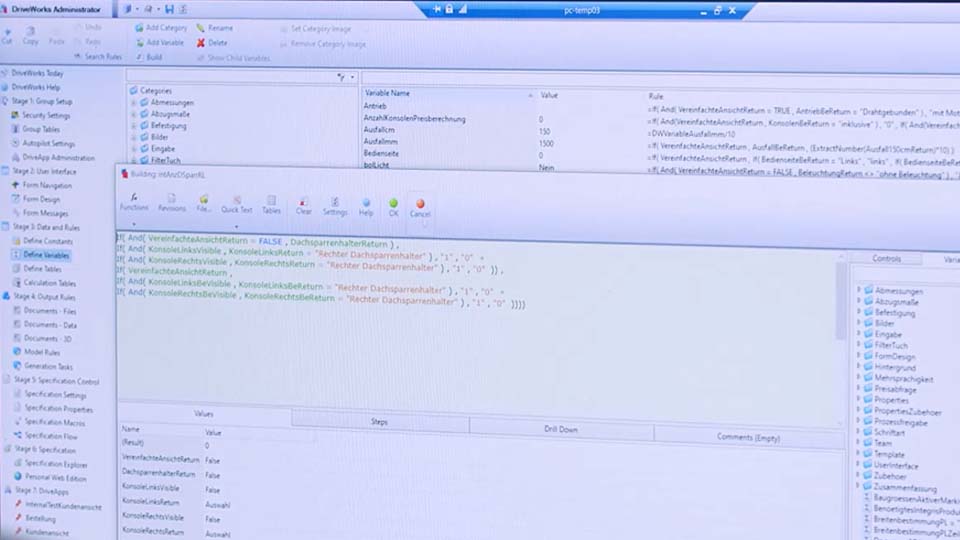

DriveWorks is a no-code solution that makes setting up and managing a design automation and CPQ solution simple.

Simple no-code setup

ERHARDT uses DriveWorks Administrator to build the user interface for their online configurator and add product rules for their ordering system, all without needing programming knowledge. The no-code solution allows the team at ERHARDT to make changes to DriveWorks CPQ as required, without the need for complex coding. New users can easily learn to use DriveWorks Administrator, ensuring that the DriveWorks implementation can always be maintained.

“We do not need any programming knowledge to use DriveWorks, we can implement and change DriveWorks CPQ as we need it” – Paul Fronert, CAD Automation at ERHARDT Markisenbau GmbH.

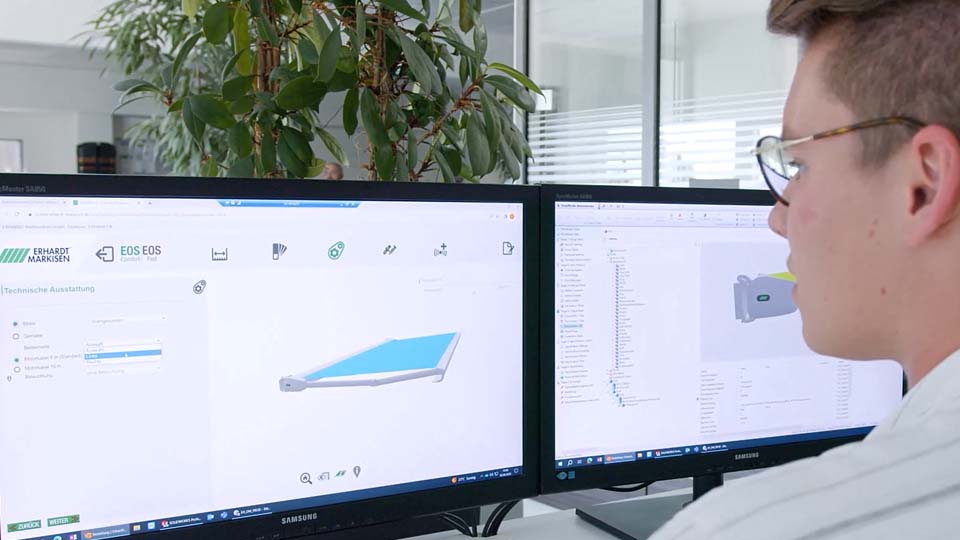

ERHARDT’s product configurator updates to show customers their configured marquee in 3D after every configuration change, along with exact pricing.

Accurate up-to-date pricing for sales partners

DriveWorks Live enables employees, sales partners, and distributors to securely access their own accounts in ERHARDT’s CPQ system through a web browser on any device. They can configure new products and manage existing orders.

DriveWorks CPQ for Manufacturing has enabled ERHARDT to provide their specialist retailers with the same pricing information they use internally. This is possible with a direct integration between DriveWorks and ERHARDT’s ERP system. For every option available in the ERP system, accurate pricing information is shared live.

“Producing in large quantities and very high quality can only be achieved using automated processes” – Thorsten Winkelmann, Area Sales Manager at ERHARDT Markisenbau GmbH.

ERHARDT also use DriveWorks Autopilot to automatically process tasks in the background. When an order is submitted, DriveWorks Autopilot automatically sends emails, generates quotations, and automatically creates the SOLIDWORKS data required for manufacturing.

Results

Connecting sales and manufacturing

Connecting sales and manufacturing has enabled ERHARDT to improve customer experience, streamline the sales process, reduce errors, and optimize engineering and manufacturing processes.

The accuracy and reliability of DriveWorks Design Automation for SOLIDWORKS has enabled ERHARDT to manufacture the products configured by the retailer without further modification by the design department.

Implementing DriveWorks Design Automation and CPQ for Manufacturing has enabled ERHARDT to keep pace with increasing demand while maintaining its reputation for high-quality products.

Try DriveWorks Pro configurator examples online

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.