The HVAC (Heating, Ventilation, and Air Conditioning) industry plays a key role in domestic, commercial, and industrial building design, construction, and maintenance.

The industry faces several challenges in a saturated market, from rapid technological advancements and fluctuations in demand to supply chain disruptions and skilled labor shortages. HVAC manufacturers use design automation and CPQ technology to enhance their manufacturing and sales processes, enabling them to operate more efficiently and competitively.

Keeping pace with technological advancements

The HVAC industry is rapidly evolving with the integration of smart and connected technologies. This continuous innovation challenges manufacturers to update their products while remaining cost-effective. Sales teams also need easy access to the latest product information to sell the best solutions without sifting through multiple product documents.

Guided selling tools give sales teams instant access to updated and configurable product options. This ensures salespeople can confidently recommend solutions, while engineering teams are freed up to focus on strategic, high-value projects instead of repetitive design tasks.

With design automation technology, HVAC manufacturers can seamlessly integrate new technology configurations into their products. By eliminating the need for extensive manual redesign, design automation solutions enable quicker adoption of new features, helping HVAC systems remain technologically competitive.

Adapting to supply chain challenges

Global supply chain disruptions—caused by natural disasters, geopolitical tensions, or health crises—can affect the availability of raw materials and components for HVAC systems.

Design automation solutions improve manufacturing agility by enabling quick reconfiguration of designs to accommodate alternative components or suppliers. This flexibility enables HVAC manufacturers to mitigate production delays and adapt to supply chain disruptions effectively.

Addressing skilled labor shortages

Recruiting and retaining talent is an ongoing challenge for manufacturers. The HVAC industry depends on skilled technicians and engineers, however, there’s a growing shortage of qualified personnel.

Design automation solutions reduce reliance on skilled labor by automating repetitive design tasks. This not only alleviates labor shortages but also enables existing teams to focus on complex, high-impact projects. By automating and streamlining routine work, HVAC manufacturers maximize their workforce’s productivity.

Standing out in a saturated market

In mature HVAC markets, manufacturers must find ways to differentiate their products to stay competitive. Innovation and customization are critical to standing out.

Design automation and CPQ solutions enable manufacturers to offer a wide range of customizable HVAC products. Sales teams can quickly configure and visualize tailored options for customers, showcasing unique product features, and enabling the design, production, and delivery of unique custom products with speed and precision.

Educating customers

Many consumers remain unaware of the long-term benefits of energy-efficient and smart HVAC technologies, including cost savings and reduced environmental impact.

CPQ solutions provide real-time pricing and savings calculations, helping sales teams demonstrate the economic and environmental benefits of energy-efficient HVAC solutions. Interactive, visual configurations enable customers to better understand the features and value of modern HVAC systems, making education an integral part of the sales process.

Ensuring regulatory compliance

Navigating complex and ever-changing environmental regulations and building codes is a constant challenge for HVAC manufacturers and their sales teams.

Design automation and CPQ solutions built on rules-based technology ensure that HVAC designs automatically comply with the latest regulations entered into your implementation. This eliminates the risk of non-compliance and simplifies the adaptation process for new standards and differences in international requirements. Sales teams can sell with confidence, knowing that all product configurations meet regulatory requirements.

Managing seasonal demand fluctuations

The HVAC industry experiences seasonal peaks in demand, especially during extreme weather conditions. Manufacturers must balance inventory, production, and staffing to handle these fluctuations.

Design automation streamlines operations during periods of fluctuating demand. By automating configuration and quoting processes, HVAC manufacturers can adjust production schedules, optimize inventory, and quickly respond to market shifts, ensuring efficient operations all year round.

HVAC manufacturers achieving success with DriveWorks

HW Ventilation has achieved 10x faster design times using DriveWorks Solo.

DriveWorks Solo has increased the speed Carroserrie Cazaux get their products into production

With DriveWorks, Monmouth Scientific has improved design accuracy and reduced their design to order process time.

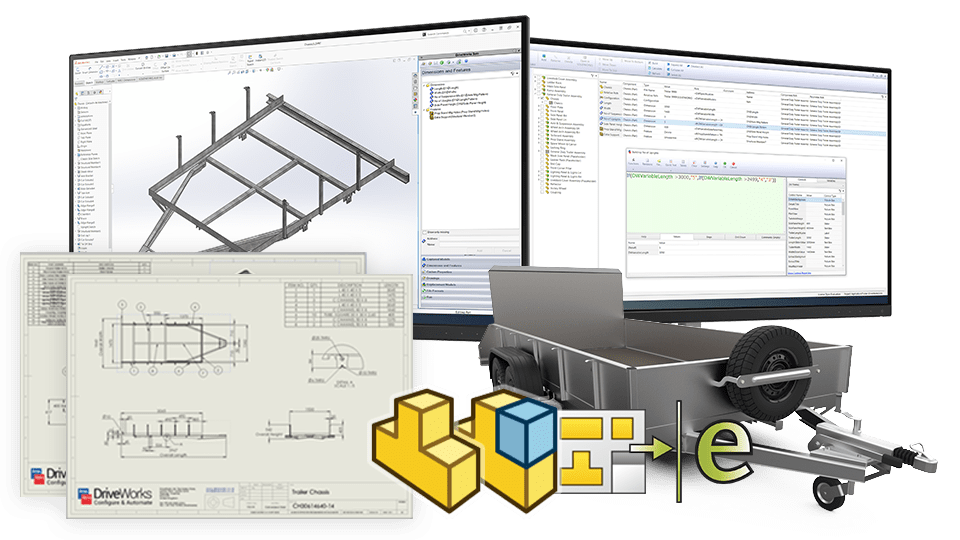

Powerful SOLIDWORKS® part, assembly, and drawing automation for HVAC manufacturers

DriveWorks Solo is the ideal solution to transform how you design, configure, and sell custom HVAC products. Using DriveWorks Solo, HVAC design engineers automate repetitive SOLIDWORKS® tasks, freeing up more time to work on new product designs. Automating and streamlining the process of designing, configuring, and selling HVAC products drives sales and improves business growth.

Make the most of a DriveWorks Solo 30-day free trial by setting clear goals, testing key features on real projects, and using the whole host of free training material provided. Use the time to evaluate its impact on your workflows and ensure it meets your needs. You can also set up a meeting with a technical expert from the DriveWorks team to help you get off to the best start.