Businesses are using technology to work smarter. In manufacturing, technology is improving traditional processes, driving the industry forward and addressing inefficiencies.

The benefits of digital transformation can reach all corners of a business. Digital transformation is improving communication and promoting collaboration. Digital-focused companies are more agile, enabling growth. These benefits are resulting in increased efficiency, more productive workforces and improved customer experiences.

There is a growing global commitment to embracing digital technologies. Businesses around the world are expected to spend $2.8 trillion on digital transformation, twice as much spent in 2020.

Businesses are levelling up, conscious of not wanting to fall behind as the world shifts to a technological-based future.

This estimated global spending can make the prospect of digital transformation daunting. It can seem out of reach for many companies.

However, with the benefits digital technologies bring, and the rate at which consumer expectations are changing, it’s important for companies to embrace digitalisation.

Whilst there are initial investments, companies are quickly seeing a good return on investment. 56% of CEOs say digital improvements have led to increased revenue.

It’s also important to find an appropriate and achievable strategy. No matter what the end goal for digital transformation is, the key is to start small. Pick a strategy that suits your organization’s current aims, with the ability to scale when appropriate. It’s important to research and experiment, learning from, and building on, your successes.

Digital Transformation in Manufacturing

We’ve spent a lot of time researching and learning about how manufacturers can embrace digital transformation. We’ve worked with customers and learnt about how they are using digital technologies.We’re seeing traditional manufacturing processes being enhanced with new advancing technologies. Technology has a huge scale of capability. While using technology to optimize these processes can imply great costs, there are ways to make it more economical.Read our tips below to find a strategy that works for you and learn how you can implement digital technologies, without huge budgets.

Digital Transformation is Scalable

Digital Transformation is not one-size-fits-all.

It is important to remember that digital transformation is scalable. The costs are relative to your organization.

You can invest as much, or as little as you like. It’s important to decide which processes are worth investing further into and start with these.

Starting small is both cost-effective and low-risk. These things could feel like minor adjustments but they often pay off straight away – they are ‘quick wins’.

Once you’ve identified these quick wins, and you’ve started to see the changes paying off, you can build on this to do more.

Identifying Quick Wins for Your Organisation

Quick wins are low risk, easy to identify, have a high probability of creating a positive impact, and don’t have to take a lot of time to implement. They also do not require large budgets.

With this, enterprises can scale digital transformation at their own pace. Doing this means that implementation is relative to capability and financial means.

Quick wins provide an opportunity to save time and costs, allowing more time and resources to be directed toward plans for a longer-term strategy and further implementation.

Here are some tips to identify quick wins in your organization:

Making the most of existing technologies

What existing technologies do you have in your business? Are you using them to their full potential? Are there features and functionality you’re not using? Does one team use a digital tool that would also be useful for another team? Do you have access to additional tools that you’re not using? For example, if you have SOLIDWORKS, are there any xpress products you could use? Xpress tools are available for free with all SOLIDWORKS licenses.

Testing technologies with free versions & trials

Free versions are a great way of identifying how useful a tool is for you and your teams. Free versions offer entry-level functionality to help you identify what you need from a tool to reach your goals. Free trials give the opportunity to test out features, and give you a head start on implementing a tool. Both options are a great way of figuring out what works for you, before committing to a tool and investing time and money.

Identifying constraints within your teams

There are often issues within processes that team members get used to, and are happy to work around. Or, perhaps because it’s always been that way, they don’t want to raise it as an issue. However, empowering teams to question processes and suggest improvements encourages them to highlight where inefficiencies could be reduced. Identifying bottlenecks, and areas where processes are often delayed is key to making improvements.

Investing in Your Workforce

Investing in digital also means investing in your workforce.

All teams can feel the benefits of digital transformation. Automating mundane, repetitive tasks and reducing errors improves job satisfaction. Using digital technologies frees up employees to be more productive, and focus on what humans do best – adding value.

From sales and engineering, all the way to HR, there will be opportunities to streamline processes. This will change the way your business operates and improve customer experiences too.

Digital transformation is different for every company so it can be hard to pinpoint where to start and what to do. Adopting a team-by-team approach helps to break the task down, and find what’s appropriate for each team.

Small steps add up. Each team could digitize one aspect of their workload, see the results and then build on this to do more.

How to Digitally Invest in Your Workforce

The implementation of technology empowers employees, giving them the means to complete tasks quickly and efficiently. Fewer errors and reduced constraints boost confidence and drives employee satisfaction.

Your sales and marketing team could implement digital automated replies to sales inquiries. HR could improve onboarding with digital learning platforms. Engineering could implement design automation to save time and reduce errors. IT could speed up processes and access to resources with cloud-based tools.

Learning new tools contributes to employee development, creating a workforce that is agile and adept at responding to new digital changes as we look to the future.

Boosting Sales with Digital Transformation

Aside from making improvements for employees and customers, digitally transforming can increase revenue. Improving sales processes improves customer experiences, builds customer loyalty, and increases sales. Resulting in more motivated sales teams and driving revenue for the organization.

Automating sales follow-ups results in a faster response to sales inquiries. Sales teams can focus on improving customer experience and building relationships. Implementing a digitally driven, streamlined sales process enhances customer experience from initial inquiry, all the way to the customer receiving the end product.

Streamlining processes improves communication between teams. Adding automation speeds up processes and reduces the potential for errors. Technology helps to meet the growing need for the fast-on-demand creation of products from customers.

Creating Solid Foundations for the Future

By starting small, businesses can grow with their technology, develop learning, and see a return on investment.

Identifying opportunities for improvement and adopting new processes builds a solid foundation for the future of your organization.

91% of companies have adopted a ”digital first” business strategy. Businesses are taking the opportunity to invest in the future of their enterprise. By keeping up with technology, they are creating an easier transition to a more digital future, making themselves more agile. This technological agility allows for the ability to keep pace with growing customer needs and demand.

Mike Yarwood

Head of Finance, DriveWorks

“Boards more than ever need to be considering scalable technical solutions to their businesses. With resource shortages becoming a more common theme in 2022, scaling at speed and accuracy is difficult to do. The focus of the board should be on ensuring that the quality and efficiency output of their processes is removing the need to hire or fix human mistakes. Business Process Automation is such a powerful tool for doing this, and one we should embrace particularly in the current climate.”

”The investment can sometimes be daunting, but actually if you consider the long-term investment & ROI, against traditional investments, they normally guarantee returns and typically payback quickly.”

How are DriveWorks customers benefitting from investing in digital?

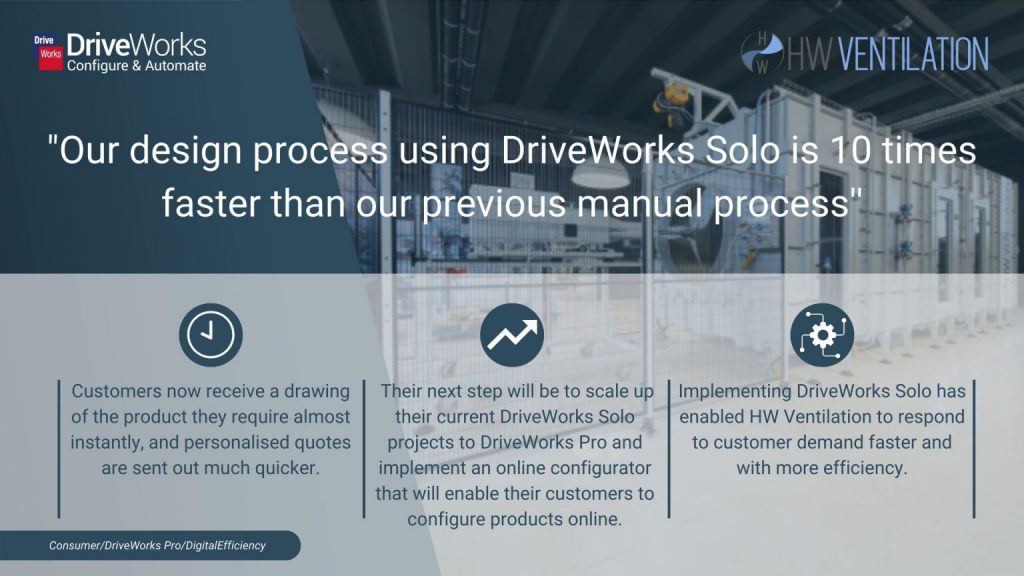

HW Ventilation, based in Rescaldina Italy, is a leading company in the ventilation and air movement systems industry. They design, produce and sell axial impellers and ventilators for industrial use.

Since implementing DriveWorks, HW Ventilation has achieved a number of goals:

- Automating their design process

- Saving engineering time spent on repetitive and low value add activities.

- Their design process is now 10 times faster than their previous manual process.

- Freed time for engineers is now spent on innovating and more reward projects

Find out more about how HW Ventilation is automating with DriveWorks here.