Industry Spotlight

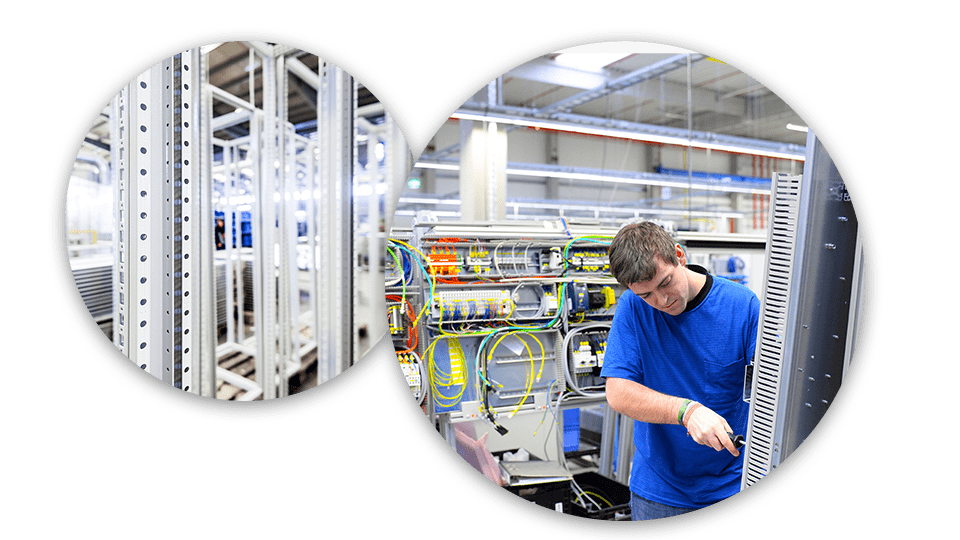

Enclosures

Overcoming industry challenges

Enclosure manufacturers face several challenges, including highly variable sizes, materials, and environmental ratings, a growing demand for custom builds, compliance requirements, slow sales cycles, and the risk of costly design errors.

Customization and variability

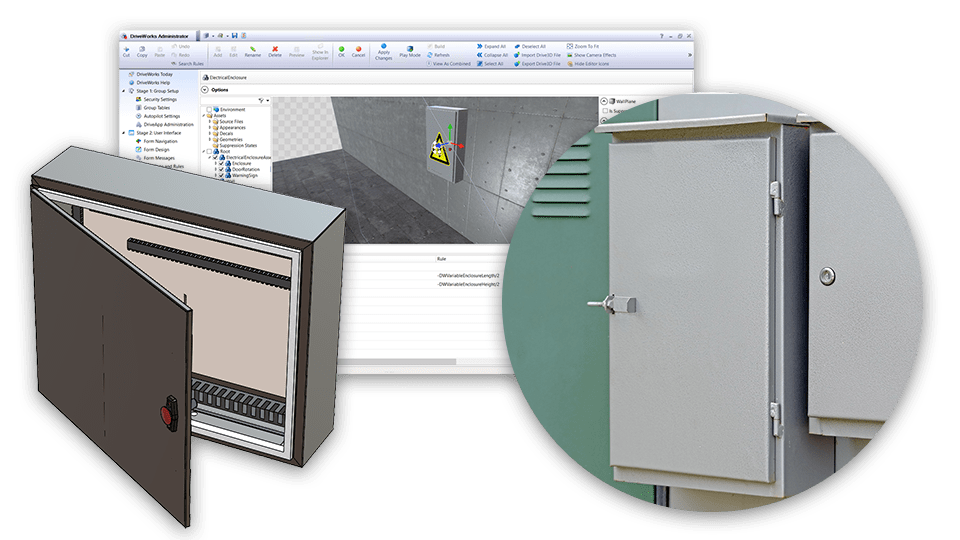

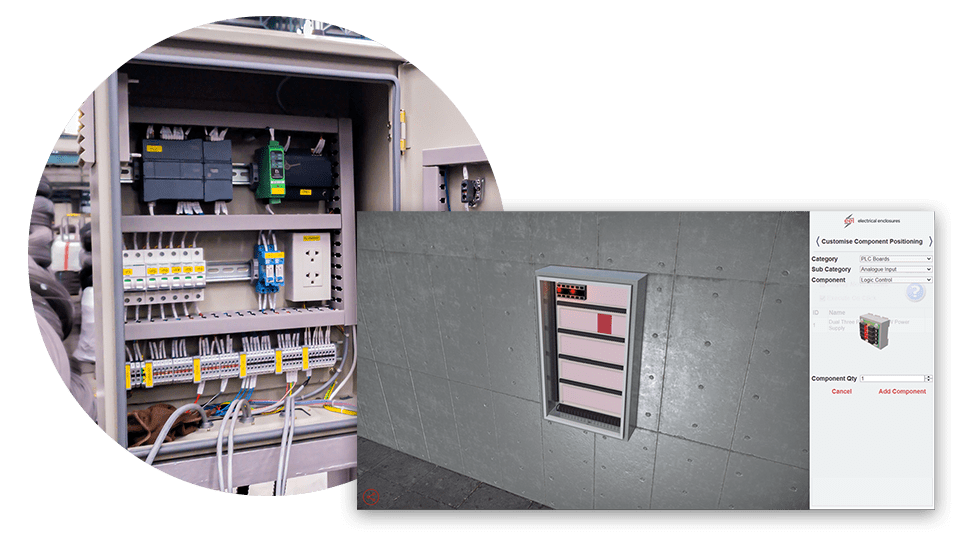

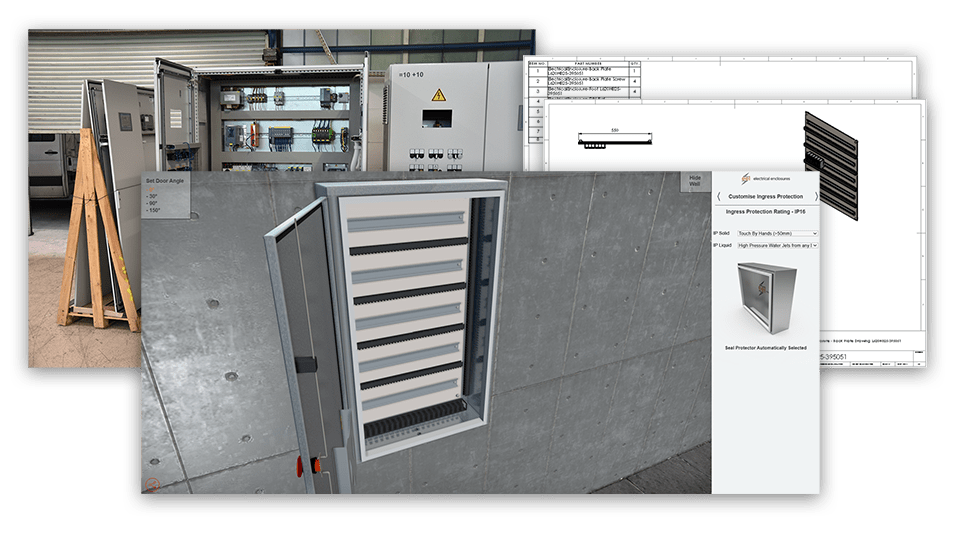

Enclosure configurations can be complex with multiple variables for dimensions, cut-outs, accessories, internal layouts, etc. Enclosure configurations can be complex with multiple variables for dimensions, cut-outs, accessories, internal layouts, etc.

How DriveWorks helps

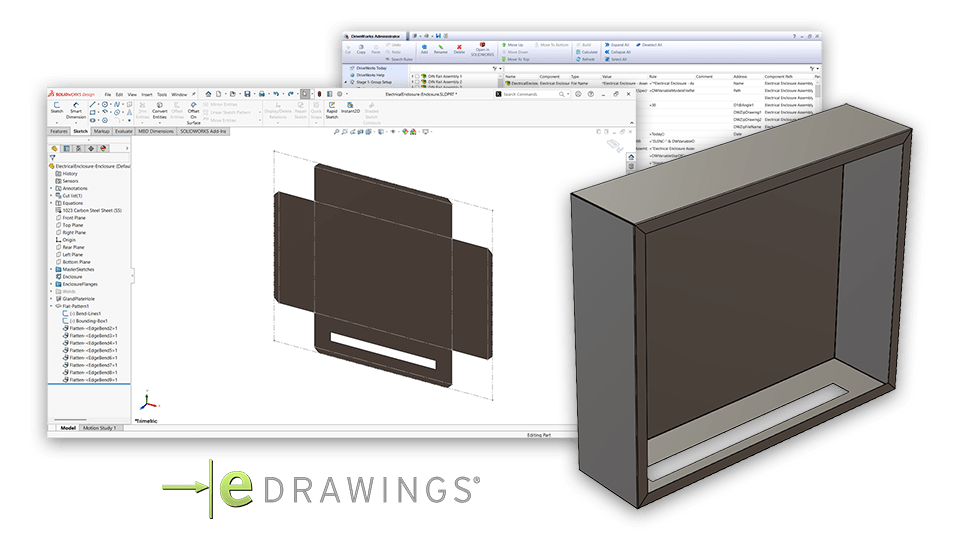

DriveWorks enables customization without additional engineering workload. Custom models, drawings, and BOMs are generated automatically, saving engineering time and ensuring accuracy.

Configuration rules prevent incompatible options, ensuring all specifications are accurate. This reduces rework volumes and improves customer satisfaction.

Accuracy

Maintaining accuracy levels is difficult with overloaded manual sales and design configuration processes.

How DriveWorks helps

DriveWorks ensures that every configuration follows engineering rules and parameters, guaranteeing accuracy. Drawings and BOMs match customer specifications, and models and drawings are generated consistently.

Guided selling enables sales teams to accurately configure complex enclosure configurations without the need for extensive product knowledge or training.

Regulatory compliance

Regulatory compliance is an important requirement of enclosure manufacturing. Supplying compliant products is non-negotiable and a key component of building customer trust.

How DriveWorks helps

DriveWorks ensures only compliant configuration options can be selected, ensuring that compliance is maintained for even the most complex customized products. Automatically-generated manufacturing documents, data, and drawings also reflect compliance requirements.

Optimized pricing

Custom enclosures have many different configuration options, making pricing difficult.

How DriveWorks helps

DriveWorks automates pricing for custom enclosures, dynamically updating prices as different product options are configured. Even for the most experienced salespeople, calculating pricing is complex and requires constant reference to pricing spreadsheets and recalculation. With automated pricing, the risk of errors is reduced, and sales teams can easily handle complex pricing models.

Shorter sales cycles

For manufacturers of custom enclosures, long sales cycles are a common challenge. Custom enclosure sales cycles involve extensive dialogue with customers, from the initial design phase through to quoting, pricing, and order confirmation.

How DriveWorks helps

DriveWorks empowers sales teams to configure products without help from engineering. Customers can visualize their options with 3D previews, and quotes are automatically generated. Additionally, quote approvals, where required, are automated, ensuring a streamlined approval workflow.

Scalability

As custom manufacturing businesses grow, manual processes become bottlenecks, slowing down growth and limiting expansion opportunities.

How DriveWorks helps

For both small companies just starting out and established manufacturers looking to grow their operations, DriveWorks scales to meet business needs. Its flexible architecture ensures that as the business grows, the technology can easily handle the increased complexity.

Customer Success Story

Extronics speed up quoting, ensure consistency, and reduce lead times using DriveWorks.

Get started with DriveWorks

Getting started with DriveWorks is quick and easy.

Get started for free

DriveWorksXpress is free inside SOLIDWORKS and you can try DriveWorks Solo free for 30 days.

Explore solutions

Learn more about how the features in DriveWorks can be utilized.

Compare software

Compare the features in DriveWorksXpress, DriveWorks Solo, and DriveWorks Pro.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.