“I used to mail Christmas cards to my friends and family. When the time came to write the addresses on the envelopes, I’d dig out my diary and look through my handwritten list, which had grown and grown over the years. It wasn’t well sorted, it had started as a list, and been added to as I’d met people. It wasn’t sorted by A to Z or by country, sometimes it grouped people together as a family, and sometimes it was an individual name. Some people had lines through them and an arrow to a new line – they’d got married, changed their names or moved at some point and I’d hastily scrawled a new address – hmm was that a 5 or an 8 there? In other cases I’d added birthdays. As the list grew, it began getting out of hand.

So several years ago I took a step back and decided to invest an hour sorting out my list. I “digitized” all the information in it. But I didn’t just copy the list, I gave it structure. I thought about how to organize the information, and what I wanted to be able to do with it, now and in the future.

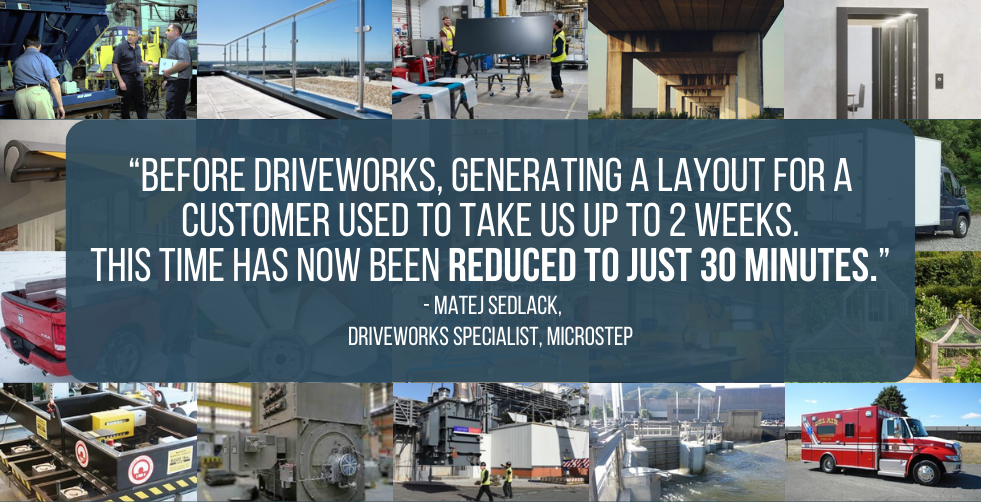

Once I had done that the rest was easy. I picked up the task for 30 minutes each day over a coffee, and within 2 weeks, I’d moved everything over.

Now that it was digitized, I didn’t need to handwrite the addresses, I could automatically print labels to stick on the envelopes. Or I could use the data at other times of the year to show me all the people with birthdays coming up in the next month.

With the data now in digital format it’s now so easy to upload all my contacts, keep them up to date in one place and send personalized messages throughout the year. Thanks to companies like Moonpig and Funky Pigeon I can even send customized cards and don’t need to go to the post office to buy stamps. A massive time saver for me and a guaranteed personal message for my friend!

That time spent transforming a mundane task has resulted in massive time savings for me and guaranteed thoughtful personal messages for my friends, ensuring we keep in touch despite our busy lives!

And although this is a personal example, the same principle applies in so much of what we do in the workplace too, especially when Digital Transformation is linked to automation.”

“So Digital Transformation doesn’t have to be daunting and doesn’t mean you need to stop everything else you’re doing. It’s a means to an end. And whilst I’m a fan of the bigger vision, it’s good to break things down, start small and little by little use saved time to Automate More.”