Building an online configurator with DriveWorks has enabled ESLA to dramatically improve customer experience and control the entire process, from inquiry to manufacturing the end product

European Special Ladders S.A. (ESLA), headquartered in Barcelona, design and manufacture tailor-made ladders, work platforms, and scaffolding. Since investing in DriveWorks Solo in 2018, they have upgraded to DriveWorks Pro and have been working with Authorized DriveWorks Services Partner, Ingenieria SAMAT to build their online configurator.

Before implementing DriveWorks software

Before DriveWorks was added to the design process, clients would reach out to the ESLA sales team with their requirements. This information was then relayed to the technical team. They would have to analyze the information and then create a new model from scratch using SOLIDWORKS, along with the regulations, calculations, and drawings for each product. Once the client had approved the model, the sales team would then create a quotation and presentation drawing for the client.

This whole process would take at least 3 days to complete.

Their configurator is transforming customer experience

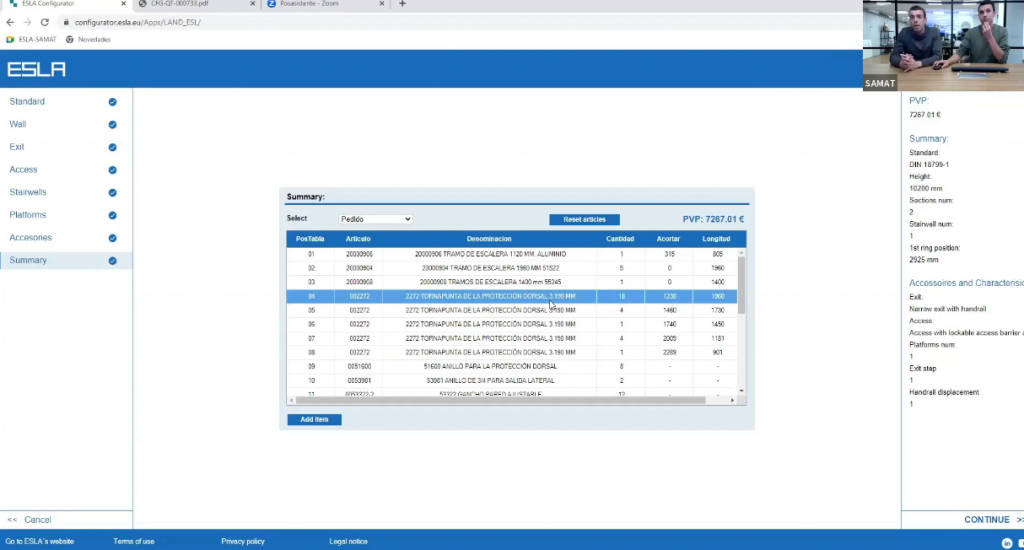

When accessing the online configurator, the customer can select the model of the ladder they want to configure. They can also select the environment on which the ladder will sit, for example, a wall. The ladder is then configured against the chosen environment and a 3D preview is displayed automatically. This helps the customer to better visualize the end product.

Every time a new specification is run, DriveWorks automatically generates a personalized PDF quotation featuring a summary of all the parts, a price breakdown for each part, as well as the final quote price for the customer. Customers are also sent a personalized cover letter. Once the customer is happy with the quotation and product, the 3D models have generated automatically in SOLIDWORKS, along with other important manufacturing documents such as the drawings, a Bill of Materials, and a Bill of Profiles.

“Before using DriveWorks, ESLA had the capacity to handle 480 quotations a year. In 2022 they made 2000 quotations”.

Ingenieria SAMAT, Authorized DriveWorks Services Partner

Minimizing chance of errors

Using DriveWorks rules technology, ESLA have ensured every ladder specified is not only manufacturable but also complies with strict regulations. If a customer inputs a design parameter that can’t be manufactured, a pop-up will appear showing that it is invalid and the customer is given a selection of configurable options to choose from.

More time for R&D

The significant time savings have enabled ESLA’s engineers to dedicate more time to research and development, along with more complex engineering tasks, improving their existing product range and developing new product lines.

Ingeneria SAMAT presented at DriveWorks World 2023

At DriveWorks World 2023 we enjoyed hearing from so many of our customers from a range of industries, sharing how they’re using the software. Ingeneria SAMAT joined us to share the story of how ESLA are using DriveWorks and it was a great opportunity to see how they have built the project.

Take a look at some of our other customers who showcased their DriveWorks journey to our community in our round up blog.

Try DriveWorks Solo for free

Get instant access to DriveWorks Solo for 30 days. No credit card required.