DriveWorks Customer Success Stories

DriveWorks is used by manufacturing companies from a range of industries.

DriveWorks is modular, scalable, and incredibly versatile. Our customers use DriveWorks in many different ways, building a Design Automation and CPQ solution to suit their needs.

Here’s what some of our customers have to say about our software.

“Thanks to DriveWorks, we provide quotes and drawings for each custom order, at no extra cost. Customers can get a quote anytime they want it, 24/7/365. With every order, customers receive everything they need. We are building customer loyalty, increasing sales and avoiding mistakes.”

– Richard Twiddy, Design Office Manager, F.H.Brundle

“For us, the most important thing about DriveWorks is our improved efficiency and reduced costly data entry errors ”

– Anthony Coombes, Design Manager, Eurobond Doors

“DriveWorks has allowed us to automate the routine processes that we undertake day in and day out, with traditional bridge design. This automatic creation of models and drawings rapidly improves the turnaround time to reach sign-off on designs and makes all downstream benefits possible”

– Dr Scott McGovern, Digital Engineering Lead, Laing O’Rourke

“For us, the most important thing about DriveWorks is that it helps us to drive consistency and maintain control of our engineering data.

Using DriveWorks, we’ve reduced the amount of time taken to complete forms from half a day to only 30 minutes.”

– Martin Clenick, Engineering Manager, Shotton Group

“We use DriveWorks for quoting and approval drawings for almost 160 teams and 530 users. We also use DriveWorks for production part component generation for various product lines and a whole bunch of other great stuff!”

– Christopher Zona, Manager – Systems Automation, Blue Giant

“We use DriveWorks for quoting and approval drawings for almost 160 teams and 530 users. We also use DriveWorks for production part component generation for various product lines and a whole bunch of other great stuff!”

– Christopher Zona, Manager – Systems Automation, Blue Giant

“Our design process using DriveWorks Solo is 10 times faster than our previous manual process. Our engineers also don’t have to waste time making drawings, and instead can focus their time on more rewarding projects.”

– Matteo Morlacci, Engineer & Main DriveWorks Administrator, HW Ventilation

“What I knew of DriveWorks was that it was a CAD automation system. But, once we started exploring the product, it became very obvious that it could do much more. The speed of DriveWorks is critical because it enables distributors to get a lead within minutes and allows us to see when the prospect was contracted, quoted and closed. ”

– Pete Robinson, Manager of Engineering Systems, WernerCo

“Thanks to DriveWorks, we have cut down design time from 40 hours to 20 hours, improving the customer experience to help enhance their decision making process.”

– Elliot Dean, Designer, Alitex Ltd

“In its current state, DriveWorks outputs 245 files, 60 of which are assemblies, 85 are drawings and the rest are parts files. With DriveWorks handling repetitive tasks, our engineers are freed up to focus on customized aspects of our designs, such as the internal cabinets of the vehicle.”

– Shawn Casebolt, Engineering Lead, PL Custom Body.

“Our order volume has increased so much since adding DriveWorks that our engineering team has more than doubled to handle the amount of requests we receive!”

– Sukhbir Singh, Mechanical Engineering Manager, Fresno Valves & Castings

“Merging projects further and adding additional functionality is a continuous process for us now, and I estimate we add additional functionality at least every couple of months. We are also currently looking into what benefits DriveWorks Pro can offer different departments outside of engineering.”

– Luke Beeson, Mechanical Design Engineer, Winder Power

“With DriveWorks we can create all drawings and manufacturing data within one day. Using SOLIDWORKS alone this process used to take three to four days.”

– Carlos Jose Bastos Grillo, Engineering Manager, WEG Energia

“Customers can now see exactly what was configured and what they will receive, long before engineering has to sink the time in to generate a complete model with full production details.”

– David Dewey, Engineer, Industrial Magnetics

“DriveWorks is interactive and fun to use, more flexible, and benefits from the excel syntax in the rules builder. The most important thing about implementing DriveWorks Solo has been the speed in getting our products into production”

– Guillaume Guerin, Design Engineer, Carrosserie Cazaux

“DriveWorks is very reliable and robust. Now I never have the feeling that I’ve forgotten something.”

“We can completely document the entire development process of a new markilux design awning”

– Alexander Metten & Daniel Becks, Designers at markilux GmbH

“Utilizing DriveWorks has allowed us to create that base model and handle that proliferation much more consistently, efficiently, and a lot faster as well”

– Justin Steele, Engineering Manager, Knapheide

“With the implementation of DriveWorks, we decrease the chance of error and repetitive tasks, and gain in quality and robustness in deliveries”

– Michael Panassol Moreira, Engineering Manager, Marelli

“Before using DriveWorks, ESLA had the capacity to handle 480 quotations a year. In 2022 they made 2000 quotations”

– Ingenieria SAMAT, Authorized DriveWorks Services Partner on ESLA, European Special Ladders

“Our configurator not only enhances the experience of current customers, but we also use it as a marketing tool to attract new clients. Potential clients can easily browse the range of products and try out the configurator for themselves.”

– Lino Peverada, CEO & Founder, PMF-System CH

DriveWorks Software

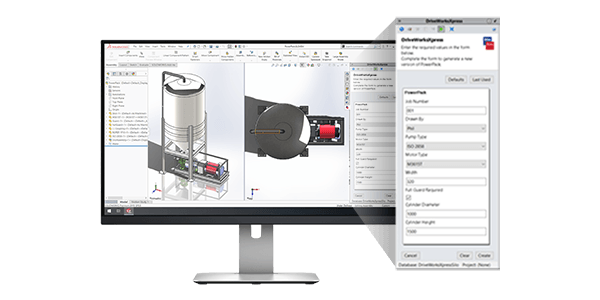

DriveWorksXpress

Free, entry-level design automation included in every seat of SOLIDWORKS.

Activate in the SOLIDWORKS Tools Menu to get started.

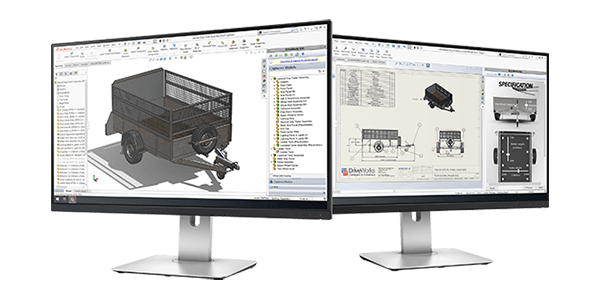

DriveWorks Solo

Powerful SOLIDWORKS part, assembly and drawing automation.

Download your 30 day free trial of DriveWorks Solo and get started today.

DriveWorks Pro

Complete SOLIDWORKS automation and online 3D CPQ configurator software.

Explore our configurator examples to see how flexible DriveWorks is.

Find Out More About What DriveWorks Can Do For You

Get in touch with us to find out more about DriveWorks, design automation and improving customer experiences.