Using DriveWorks, Extronics have streamlined processes, reduced lead times and driven product development, all whilst ensuring consistency and quality.

Extronics are headquartered in the UK, and operate around the world. They specialize in developing and manufacturing equipment for use in hazardous areas. Their aim is to to deliver world-class products and solutions that help their customers work smart, safe, and connected.

We recently visited Extronics to chat with Nick Saunders, Operations Director, who has led the implementation of DriveWorks at Extronics.

We saw where they design and manufacture their products, and learnt more about why they chose DriveWorks, and what they’ve achieved as a result.

Putting Customers and Quality First

Extronics were seeing increased demand for wireless products. They were receiving more and more inquiries for different devices, not just industry standard devices.

When a customer came to them with a request for a custom solution for a wireless product, it would need to go through an assessment process. For each custom request, a member of the Extronics’ technical sales team would need to review the device before they were even able to provide a quote.

Extronics’ lead times were extending and they recognized they needed to make a change.

As Extronics’ specialize in products for hazardous environments, it’s vital their products are correct and safe. They needed a solution to improve lead time, without taking shortcuts.

“Bringing wireless technology into hazardous areas isn’t easy. Extronics made a conscious decision to invest in technology to streamline this process.”

– Nick Saunders, Operations Director, Extronics.

Speeding Up Processes, One Step at a Time

Extronics decided automating their processes would remove friction and barriers for their customers. It would make it quicker and easier for them to deliver products to their customers.

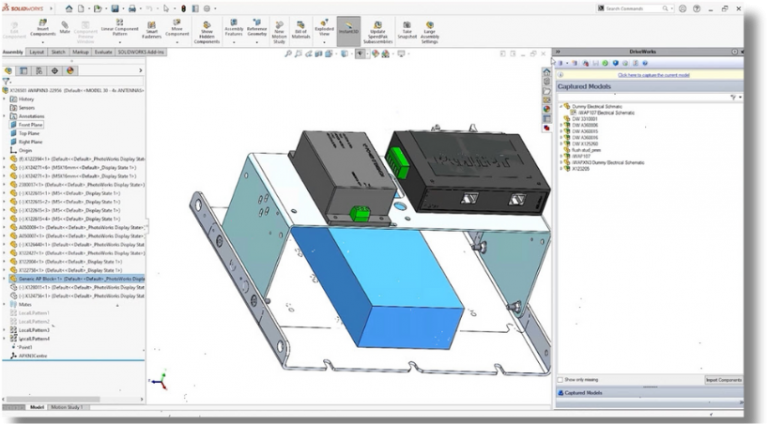

All Extronics’ CAD models are in SOLIDWORKS so they were looking for a solution that integrated well with SOLIDWORKS. DirveWorks was the obvious solution.

Extronics have a team called the Configured Products Group (CPG). They are the solutions experts, any bespoke or custom orders would go through the CPG team. It made sense that that CPG team would implement DriveWorks, to put their knowledge and expertise in to their DriveWorks project.

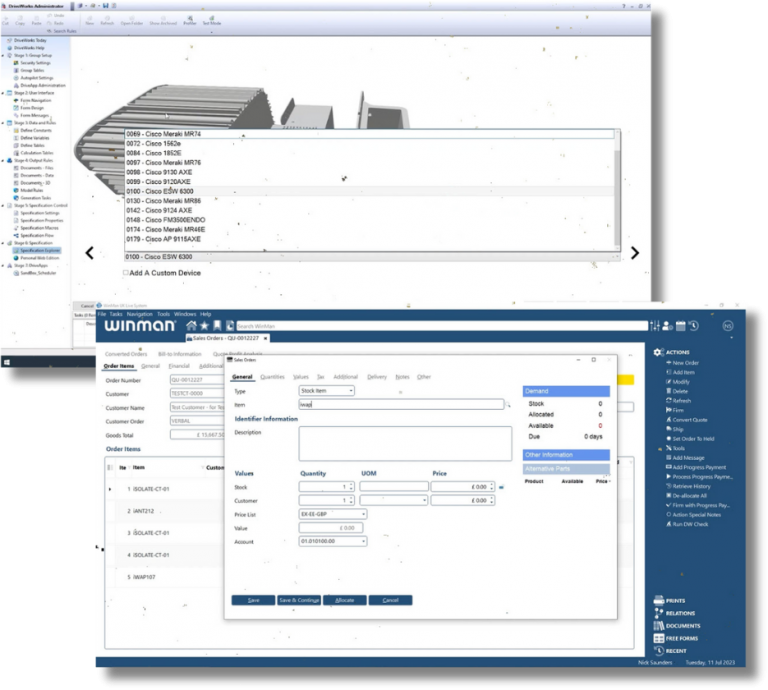

They started by creating a price configurator for their Sales Team. Extronics have integrated DriveWorks with their existing ERP solution, so the Sales Team can generate quotes directly within the ERP system. This was a big win for the Sales Team, as this was previously a manual and time-consuming process requireing specific technical knowledge.

After implementing the price configurator, Extronics then moved on to automation of the CAD models. Automated documentation came a bit later.

Extronics have taken an iterative approach to implementing DriveWorks. They built specific solutions that resulted in wins for the company, got value from those and then moved on to another part of the project.

Driving Product Innovation

When reviewing their SOLIDWORKS models, Extronics realised they needed to make some changes to their models, to make them more suitable for automation.

This prompted Extronics to look at their products in a different way and opened up opportunities that they hadn’t previously considered. They were able to do new things with their products, and allow customers to configure solutions in a way that they couldn’t do before.

Reducing Errors and Driving Consistency

Before using DriveWorks, Extronics would sell a product, it would then need to be engineered, then it would be sent to manufacturing. This was all done manually and there was high potential for misalignment between departments.

DriveWorks has driven consistency.

At the point of placing an order, sales are able to give documents to the customer to confirm what they have ordered. The engineering of the solution is automated and rules-based.

Extronics now have consistent outputs that are used by all teams, including manufacturing, ensuring the customer gets exactly what they need.

Extronics have taken a complicated assessment process, that was taking days previously, and reduced it down to a matter of minutes with DriveWorks.

Next Steps with DriveWorks

Extronics are planning on taking the benefits of DriveWorks even further. Their plan now is to build an online product configurator, so customers can configure their ideal product on the Extronics website, without needing to get in touch with anyone from the Sales Team. This will give customers the ability to configure their desired product, see what’s possible and really understand what Extronics can do for them online, anytime.

“DriveWorks is a tool that allows us to accelerate our digitalisation strategy”

– Stuart Milne, Marketing Manager, Extronics.

Try DriveWorks Free for 30 Days

Get started with DriveWorks.

Download and use DriveWorks Solo free for 30 days.

Available to anyone with SOLIDWORKS.