The Success of Digital Technologies within Manufacturing- How Can Organizations Measure?

Digital transformation is the adoption of digital technologies to create new, or modify existing, processes within an organization. Adopting digital technologies is enabling companies to increase efficiency, improve accuracy, streamline business-to-consumer relations, boost speed, and innovate.

Digital Transformation can have an enormous impact on an organization and its processes. Monitoring and measuring is key to knowing what is working and why.

Here are some of the ways you can measure success:

- Identifying and measuring Key Performance Indicators (KPIs)

- Calculating return on investment (ROI)

- Gathering employee feedback

- Gathering customer feedback

- Measuring organization agility and innovation

Technology enables manufacturers to design quicker, communicate better, and transform the customer experience. What works for some, may not work for others. Measuring the success of technologies is critical to ensuring that your organization is digitally transforming in the most appropriate way.

Why are Digital Technologies Important for Manufacturing Businesses?

Digital technologies are important for organizations in the manufacturing industry for many reasons. Digital technologies like automation help to improve the efficiency and productivity of manufacturing processes. Eliminating errors improves the quality of products and services and reduces time-consuming, costly delays.

Implementing digital technologies into the manufacturing process improves an organization’s agility, making them more responsive to meeting customer needs and giving them flexibility on product lines.

Digital technologies have so many possibilities and can provide manufacturing companies with helpful insights and data that become integral to decision-making. Organizations can gather data on production processes, customer feedback, and product quality to make more data-driven decisions.

Map Out Before Measuring

When planning out your approach to digital, it’s often difficult to know where to start and what will work. It’s important to create a roadmap that highlights the areas you want to improve and document where in these areas are the processes struggling. By doing this, not only are you able to apply the appropriate technologies easier, but you can revisit this to see the progress made. After implementation, do these bottlenecks still exist? Have the technologies you implemented removed or reduced the problems within those progresses? It can be easy to get carried away and use technology that helps but doesn’t solve the problems you were initially wanting to resolve. Regular reviews of your roadmap can help you stay on track.

It’s also important to find an appropriate and achievable strategy. No matter what the end goal for digital transformation is, the key is to start small. Pick a strategy that suits your organization’s current aims, with the ability to scale when appropriate. It’s important to research and experiment, learning from, and building on, your successes.

Setting Targets

The prospect of creating long-term goals to digitally transform can seem daunting. It’s important to remember you don’t have to make big changes all at once. Digital transformation is scalable. Sometimes, with what feels like a ‘big problem’, it can be easy to assume it needs a big solution, requiring a lot of time, money, and change. This doesn’t need to be the case, there are ways to effectively consider the cost and make time for a digital transformation strategy.

Help yourself by setting targets.

First, define your objectives- what is it you want to achieve by implementing digital technologies? Are they specific and measurable? Without measurable targets, you will be unable to easily see the difference it has made to the business. Undocumented data can cause problems further down the line too, particularly when you may be proposing the help of new technology for other projects or processes.

Identify key performance indicators (KPIs)- Use your defined objectives to identify areas and know the kind of results you’d like to see from the implementation of digital technologies. This will help you to measure progress towards the objectives.

Setting specific targets- Use both your objectives and your KPIs to set specific targets that you’d like to hit. An example of this might be to make the design to manufacturing time 30% faster per project.

Create an action plan- Look at your objectives and the targets you’d like to achieve and then review what digital technologies would be appropriate to apply to your processes. Focus on what your goals are and act accordingly. It can be easy to become overwhelmed by the number of technology offerings and you run the risk of implementing initiatives that don’t solve current problems. Simplify current processes and then build on this.

Monitor progression- You can track the progress of a project using data and analytics from digital technologies too. Regularly doing this helps you to see if you are working towards success, or if you need to alter your action plan.

Setting targets when digitally transforming is important for staying on track to achieving your objectives and focusing efforts exactly where the original problems were highlighted.

Focusing on initial goals reduces the time and cost required to plan and implement the strategy and also helps with employee engagement. Small changes over a period of time are much easier to accept and adapt to. Breaking down the task makes it more attainable and there’s also a quicker sense of satisfaction. Seeing results sooner boosts attitudes toward digital transformation and increases adoption and acceptance.

Key Metrics to Track

According to McKinsey, there are 5 key metrics for business leaders to track when measuring the success of digital within a company.

- Return on digital investments- Measuring ROI is a standard and necessary process for anything that a business invests in. Digital technologies are no different. Leaders should look at the value provided by the implemented digital initiatives and consider that not acting on investing when competitors are can mean falling behind.

- Percentage of annual technology budget spent on bold digital initiatives – With investment comes risk. But risks can pay off. Those who are only using a small amount of their technology budget to implement the most obvious strategic digital initiatives are unlikely to see much of an ROI. How business leaders allocate budgets to things like digital can be telling of how a company will react to a technological future.

- Time to market of digital apps- In the fast-paced world that is constantly evolving to technology, the speed at which companies adopt technologies is integral to success.

- Percentage of leaders’ incentives linked to digital- All leaders within a business must be aligned and held accountable on the theme of digital transformation. Within companies, there can be different views due to traditional and more modern-style of technical leadership roles. It’s important to review this and make sure that there is an ability to align incentives to support digital company-wide.

- Top technical talent attracted, promoted, retained- As digital technologies scale, having appropriate talent is a crucial driver in the success of a company. Companies that have individuals with expertise in data engineering, analytics, design and user experience, and core technology are in good stead for the technological future.

Measuring More Than Numbers

Often numbers, targets, and KPIs are what come to mind when thinking about measuring the success of a project. However, beyond this, the people behind the implementation of this technology within an organization are integral to its success. It is important to consider how they feel, and how technology will make a difference to your workforce.

Gaining employee feedback is critical for successful digital transformation projects. By involving employees, and acting on their feedback, you can improve the user experience, increase or decrease adoption, and identify areas for improvement. All of this goes towards measuring the success of the implementation of digital initiatives.

As employees will be the ones using the technology, they are in the best position to feedback and help leaders stay well-informed on the effect it is having beyond the numbers. As implementing technologies is an ongoing process, there will be areas that workforces will comment on to suggest areas of improvement. When workforces feel valued they are more likely to be better engaged in the transformation.

All teams can feel the benefits of digital transformation. Automating mundane, repetitive tasks and reducing errors improves job satisfaction. Using digital technologies frees up employees to be more productive, and focus on what humans do best – adding value.

Customer feedback is also useful to gain insight into how your business processes can be, or have been, improved. Perhaps a returning customer comments on how an order was quicker this time, with no detriment to the quality. Or you gain more orders after implementing an online configurator, and the sales team reports back on customer satisfaction with the online tool.

Digital transformation reaches beyond hardware, data and analytics. Understanding that success can be measured not only in numbers but in feedback from human workforces and your customers can help to accelerate the promise of digital within businesses.

Adam Baker

Product Manager – Integration, DriveWorks

“Success should be considered at all levels of the business, the most successful projects give time back to the employees so they can focus on the innovating aspects of their role whilst automating mundane day-to-day activities. This then feeds back to the management team, who can focus on supporting their team instead of firefighting.”

How are DriveWorks Customers Embracing Technology?

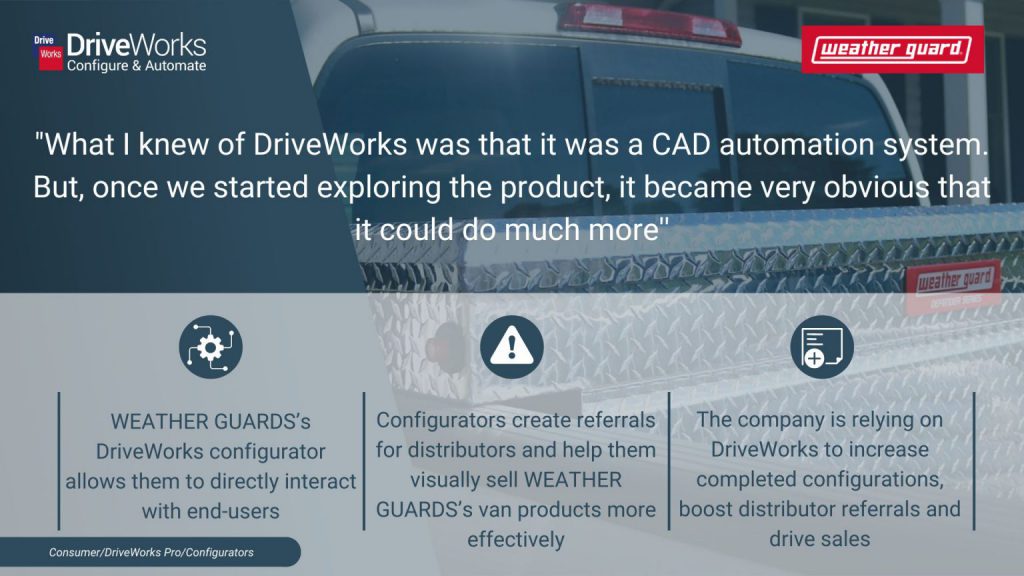

WEATHER GUARD, a WernerCo brand, is an industry leader in truck and van storage equipment, including truck boxes, drawer units, shelving, cabinets, and racks for trucks, vans and utility vehicles.

Since implementing DriveWorks, WEATHER GUARD has achieved a number of goals:

- Generating more revenue than ever before.

- Allow stakeholders to know exactly how much revenue is coming through the configurator to measure ROI.

- Dramatically reduced their engineering time, saving at least one full day of labor per configurator request received.

- Achieve longevity, and ease of use while bringing an intuitive and engaging experience to end users.

Read more about WEATHER GUARD’s success with DriveWorks here.