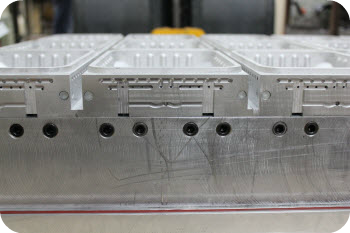

Pattern Forme Limited are one of the principle Thermoforming Tool Makers in the UK, with an excellent reputation for innovation and reliability. Their products include manufacturing Patterns, Designing and Machining Thermoforming Tooling, Punch and Die Tooling, and CNC High Precision Components using a range of materials, serving the Vacuum and Pressure Thermoforming Industry.

We recently caught up with them to discover how they are using DriveWorks Pro and the results that they’ve seen.

So how are you using DriveWorks?

Our DriveWorks configurators tend to vary with each toolset requirement, but overall we input key data from the product we are trying to form and use DriveWorks to re-configure the tool components to suit the new design.

How did you ‘Design to Order’ before you had DriveWorks?

Before using DriveWorks, we used a variety of 2D and 3D CAD packages to take the customers’ requirements from a layout to fully programmed CNC components.

However this was time consuming and using DriveWorks has allowed us to reduce the amount of time needed for the bulk work, which frees up time for our designers to work on innovative and advanced projects, helping them to produce a better designed tool.

How does DriveWorks benefit your customers?

The main benefit for our customers is definitely the quick turnaround when designing, manufacturing and subsequently delivering their orders.

Using DriveWorks enables us to cut the time needed when designing tools, which helps us to get the models into our CNC department sooner. This means that the time taken to complete the order is reduced, so the finished product is sent to the customer sooner.

Overall, what’s the most important thing about DriveWorks for Pattern Forme Limited?

With customers requiring a quick turnaround during the design and manufacturing stages, we needed a way to reduce the design time, without reducing quality or accuracy. DriveWorks has solved this problem and allowed us to adapt and advance.

For us, the most important thing about DriveWorks is definitely the time saving benefits. As we are saving time during the design stage, we are able to accommodate much tighter delivery schedules whilst still having the room to innovate and adapt to meet our customers requirements.

Find out more at patternforme.co.uk

See DriveWorks Pro in action and have a go at configuring products to your own specifications by visiting our Online Sales Configurator, Configure My Product, or by visiting driveworkslive.com