Overcoming challenges in transportation manufacturing

Transportation manufacturers face several challenges. In an increasingly customized and competitive industry, manufacturers need to streamline processes and maximize sales. Some of the more significant challenges include complex configuration demands, the cost and availability of resources, regulatory compliance, and maintaining efficiency in design and production processes.

Manufacturers in the transportation industry use DriveWorks design automation, sales configurator, and CPQ solutions to streamline their manufacturing and sales processes, enabling them to operate more efficiently and competitively.

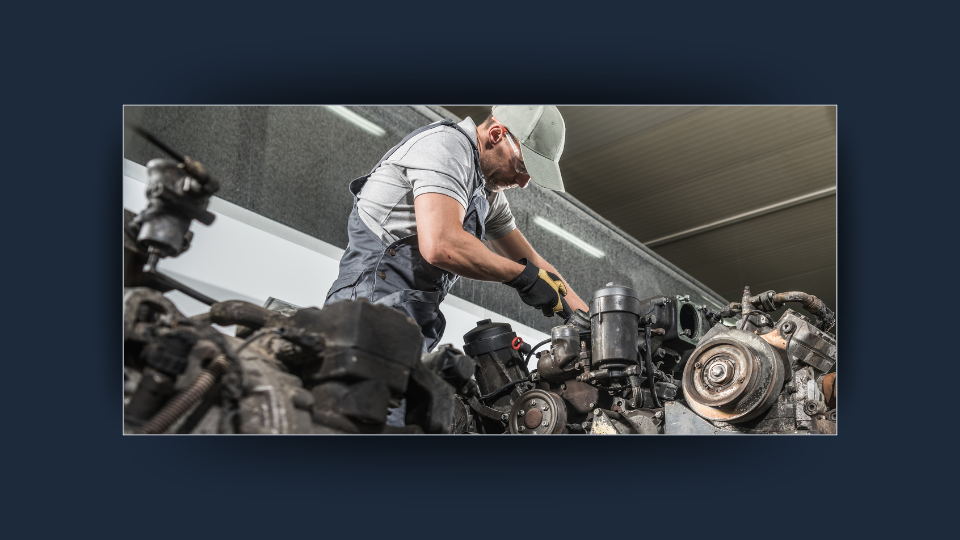

Complex customization requirements

One of the biggest challenges for manufacturers in the transportation industry is meeting the increasing demand for complex configurations. This can lead to design and production inefficiencies, with each unique order requiring significant time and effort to design.

DriveWorks enables transportation manufacturers to create configurable design templates. Engineers can define rules and parameters that guide the customization process based on customer requirements. This ensures that each order, even if highly customized, follows a standardized and automated design process.

Automating repetitive and mundane design tasks delivers improved accuracy, quicker design turnaround times, and less rework. Additionally, design engineers have more time to focus on value-added tasks such as new product development.

Long sales & engineering cycles

The design engineering workload for custom trucks, trailers, and transportation products can be time-consuming and prone to error. Manual design processes for “same but different” products are labor-intensive and often develop bottlenecks. This leads to longer sales & engineering cycles and potential lost sales.

DriveWorks enables transportation manufacturers to save time and speed up sales & engineering cycles by automatically creating accurate SOLIDWORKS manufacturing drawings.

Transportation manufacturers rapidly generate quotes and proposals based on customer inputs, enabling them to respond promptly to inquiries and secure orders more efficiently. Faster turnaround times for quotes increase sales and improve customer satisfaction.

Compliance & regulatory requirements

Ensuring safety and regulatory compliance is an integral part of assembling trucks and trailers. With numerous regulations, compliance can be complex and require additional resources.

DriveWorks enables transportation manufacturers to add compliance and regulatory requirements into their design rules. This ensures that each custom product complies with relevant safety standards.

DriveWorks guided selling tools enable sales teams, customers, and distributors to access up-to-date, compliant configuration options. Ensuring all product configurations are compliant enables sales teams and resellers to sell confidently, with the knowledge that every product configuration is valid and accurate.

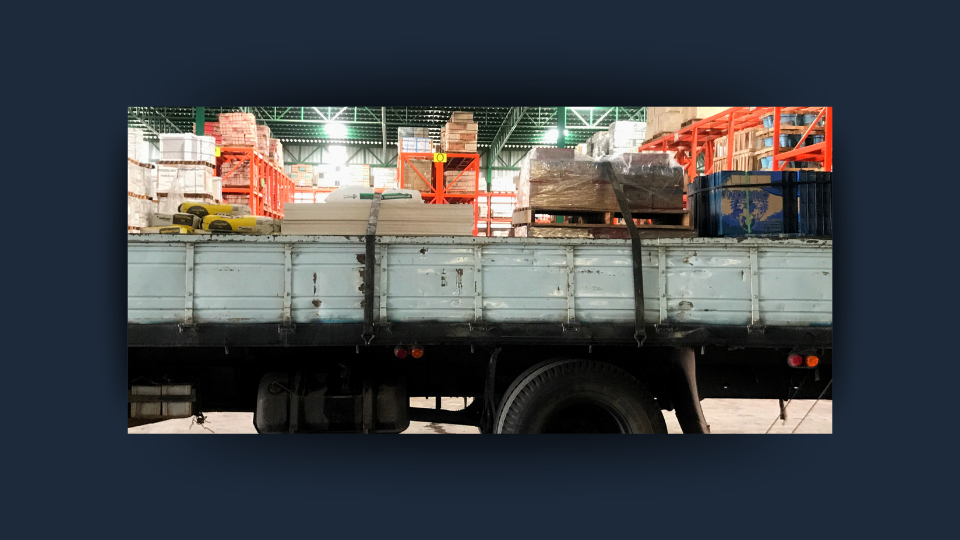

Material optimization & costs

Made-to-order vehicles, trailers, and transportation products often have specialized features that require unique materials. Inefficient use of materials can drive up costs and impact sales and revenue.

DriveWorks can be integrated with real-time data sources to monitor material costs and availability. By automating the quotation process, prices are automatically adjusted based on fluctuations in material costs, ensuring accurate and competitive pricing. This level of flexibility enables manufacturers to operate dynamically and avoid costly delays.

The automatic creation of BOMs helps streamline the material procurement process and enables manufacturers to plan out materials and resources more efficiently.

Streamlining the configuration and quoting process

Using DriveWorks, Waimea manage complex configurations with ease.

Waimea, based in New Zealand, manufacture specialist utility vehicles. Their vehicles are used across a range of industries, including power & energy, forestry, and road & traffic. They needed a solution to enable their sales teams to configure and manage their custom vehicle range.

Before using DriveWorks, Waimea managed their configurations using Excel spreadsheets. There are 30 combinations of trucks and equipment, each with long lists of build materials. Each combination required its own spreadsheet, with hundreds of rows. This became unmanageable as different members of the Waimea team made live changes in the spreadsheet, without knowing the impact on data elsewhere.

Waimea’s DriveWorks CPQ implementation enables their sales team to configure custom-built vehicles with ease and provide accurate quotes. Using a configurator solution with guided selling technology, they can configure custom vehicles with viable optional extras. Waimea integrated their DriveWorks implementation with SQL and PDM, ensuring all data is taken from one source of truth.

Waimea have added component costing to their configurator so the sales team can provide customers with fast, accurate pricing. This improves the buying experience and increases the likelihood of purchasing.

The salesperson can see a complete quote breakdown so they can be confident in telling the customer how much their truck is going to cost.

Ira Dudley-Bestow, Data & Modelling Engineer at Waimea

Configure, design, sell, and manufacture custom products faster

DriveWorks technology enables you to accurately configure custom products, calculate pricing, and automatically create documents and data for sales and manufacturing.

Learn more about DriveWorks technology and how your business could benefit with a DriveWorks demo. One of our technical experts will take you under the hood of our technology and explain the features of our design automation, product configurator, and CPQ for manufacturing solutions in more detail.