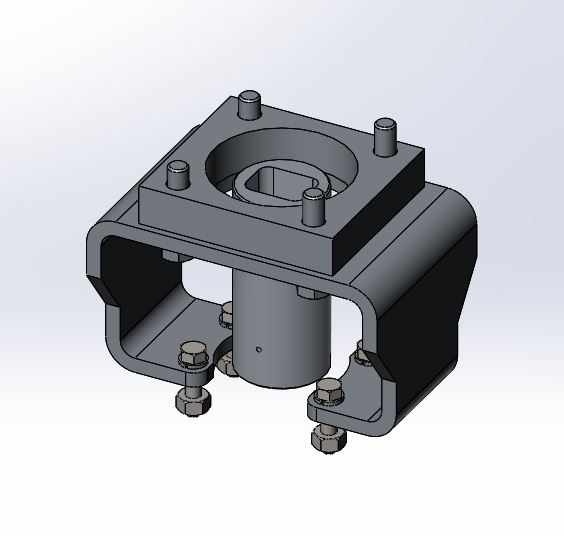

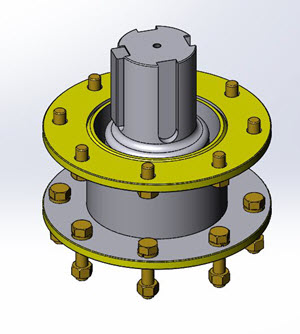

VanAire Inc, headquartered in Gladstone Michigan, develop Engineered Valve Automation Hardware. The company predominantly works with metal and makes parts that connect valves and actuators on pipelines.

We caught up with Ismael Lopez, CAD Administrator at VanAire, at a recent DriveWorks Drivers event where he spoke about his experience of using DriveWorks over the last 7 years.

Ismael is the DriveWorks Administrator at VanAire and was first introduced to DriveWorks at DriveWorks World in 2014.

Beginning the DriveWorks Journey

VanAire have been using DriveWorks since 2006. Initially, the software was used solely as a design automation tool for the engineering team. Engineers with SolidWorks were able to configure new brackets using DriveWorks Pro User to generate the manufacturing data.

When Ismael joined the team, the company wanted to see what more they could achieve. The first step was to further streamline their Design Automation projects.

Although the original projects saved time, they relied on stepping through several forms and had not been optimized for user experience. Ismael reduced the number of forms, streamlining the process. By doing this VanAire sped up their design automation project even more.

What used to take 15-20 minutes has now been cut down to 3-4 minutes. This includes generating all the manufacturing data and drawings.

As the company had already invested in DriveWorks they knew it would make good commercial sense to expand its use to other teams.

Introducing DriveWorks to the Shipping Team

The Shipping Team were one of the first non-technical teams to be introduced to DriveWorks, with the target of automating the creation of shipping labels.

Before using DriveWorks, the manual process of creating shipping labels involved using an excel spreadsheet and a member of the design team creating the label, attaching it to the PO and then sending it over to the Shipping Department.

To automate this process, VanAire used DriveWorks Autopilot. All the information required is saved in SQL, and a database connector is able to pull that information at the back end.

The project itself creates a label, saves a label and prints out the correct number of labels automatically.

Ismael expands on this, saying:

“Everything is done automatically and DriveWorks has made that very easy for us, as we used to have lots of issues with the previous manual system.”

Integrating DriveWorks with their ERP System

With the label project exceeding their expectations, VanAire moved on to their next DriveWorks project; integrating DriveWorks with their ERP system.

Using ODBC connectors, they were able to start pulling information from their ERP system, into DriveWorks.

They then took this integration a step further and decided to connect their ERP system even more by including SOLIDWORKS designs in the ERP system.

Now, using DriveWorks, they can create a specification, have it in the ERP system, and print it.

Before implementing DriveWorks, this process could take up to two hours, before the information was even created within their ERP system.

Automating Costings with DriveWorks

VanAire wanted to implement DriveWorks into even more of the company’s systems. Costings was the next division to implement the software.

Ismael has been able to pull some information from the ERP system itself and he has also created a feature-driven costing system.

The new costing system takes into account specific features and sizing, as well as how long it actually takes to make the parts.

Before implementing DriveWorks, it could take up to a week to get actual costing if it was a big order. Using DriveWorks, Ismael has been able to drop it down to seconds for each part.

The sales team were introduced to DriveWorks at this point and the software has now been implemented company-wide.

Sales Team Running Specifications

The Sales team can now run specifications themselves, meaning the design team have more time to focus on innovative R&D projects.

The sales team can also instantly access information, such as the customer’s purchase history.

This means they know their customers better, which in return leads to more positive relationships and continued custom.

Ismael says:

“DriveWorks has made the whole process from the customer’s initial inquiry, to getting a quote and receiving their order much easier and quicker.”

VanAire’s Response to Covid-19

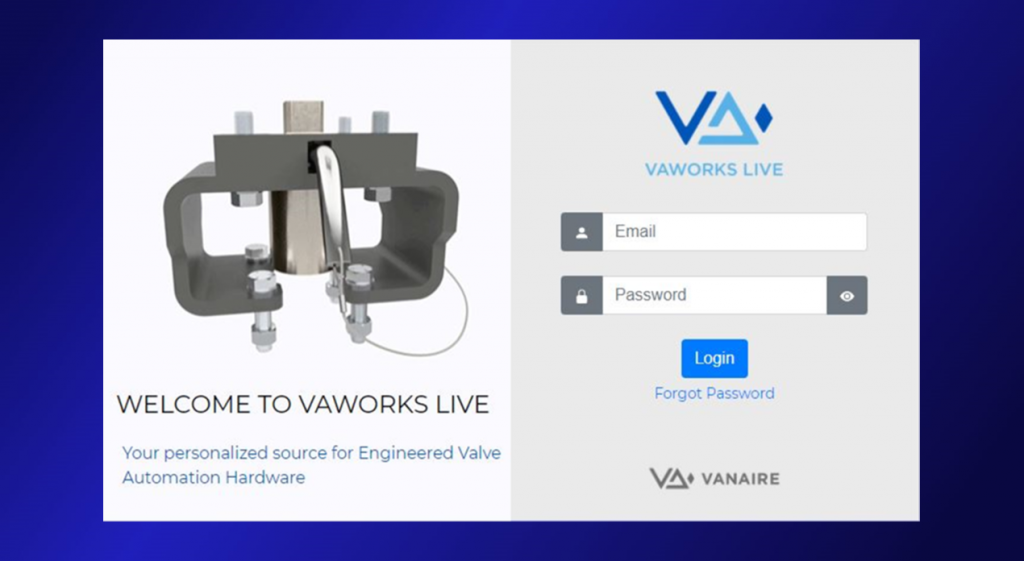

In 2020, in response to the COVID-19 pandemic, VanAire decided to create an online configurator for their customers to use.

A customer can access the site and select their product combination. This information is not only submitted to the website but directly to DriveWorks.

All the data is generated automatically, including the model. It also triggers an email that is sent to the customer with the quote for their selection.

Continued Success

Over the past 14 years, VanAire have achieved a lot with DriveWorks and completely innovated the way they work using the software.

DriveWorks has been implemented across the whole business and as we can see through the creation of their online sales configurator, the company is showing no signs of slowing down.

We can’t wait to see what the next 15 years holds for VanAire and DriveWorks!

Suitable for Any Industry

DriveWorks product configurator software is used by companies of all sizes. It’s suitable for any industry where quotes or 3D files and drawings are part of the sales to manufacturing process.

See how versatile and customizable it is by having a go with our online configurator examples on www.driveworkslive.com