Configuring a Custom Conveyor

The global pandemic has led to fewer face to face meetings. And it’s also making 3D visualization and online configuration, essential commercial tools for manufacturers of custom or customizable products.

Creating custom products and delivering a personalized digital experience can increase profitability for manufacturers who sell to other businesses.

More buyers are also looking for products that meet their exact needs and expect shorter sales cycles and better buying experiences.

Implementing an interactive online sales configurator enables your customers, distributors, or inside sales teams to configure a custom product, get instant quotes, see accurate delivery dates, and even place their orders, in one simple session.

Online sales and digital manufacturing are key aspects of digital transformation.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action. Anyone can use the online configurators, created using DriveWorks software.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom conveyor system online.

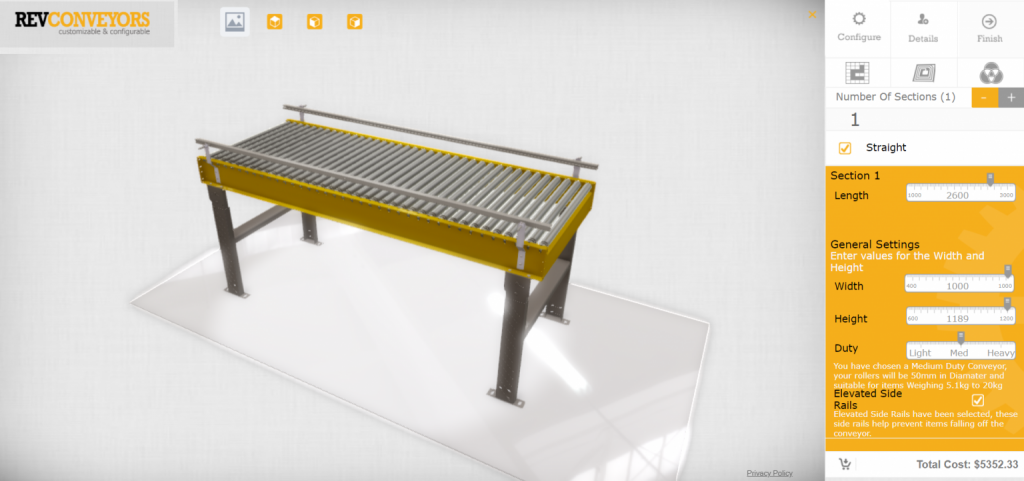

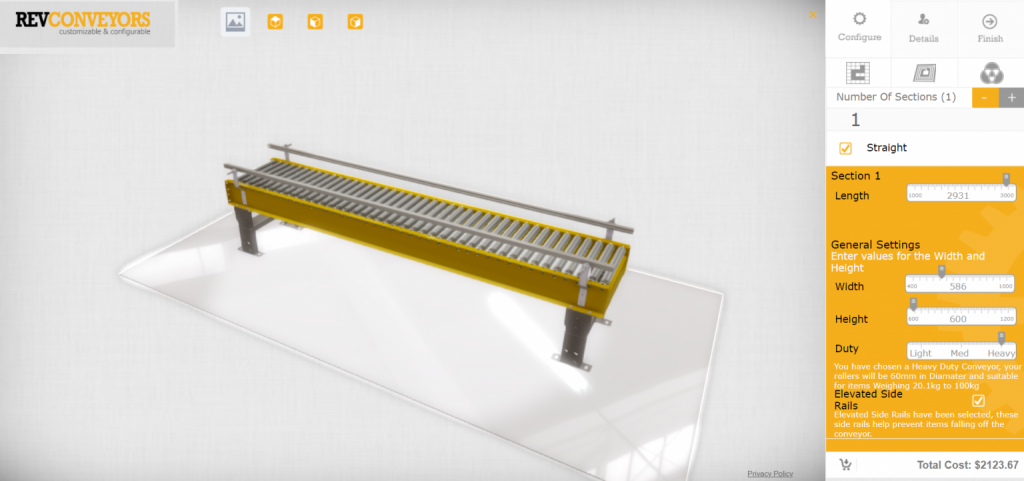

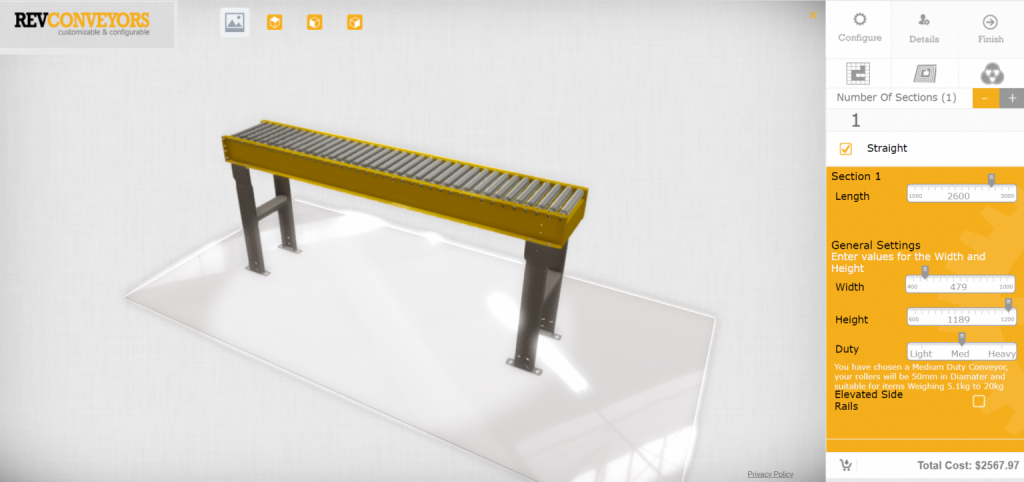

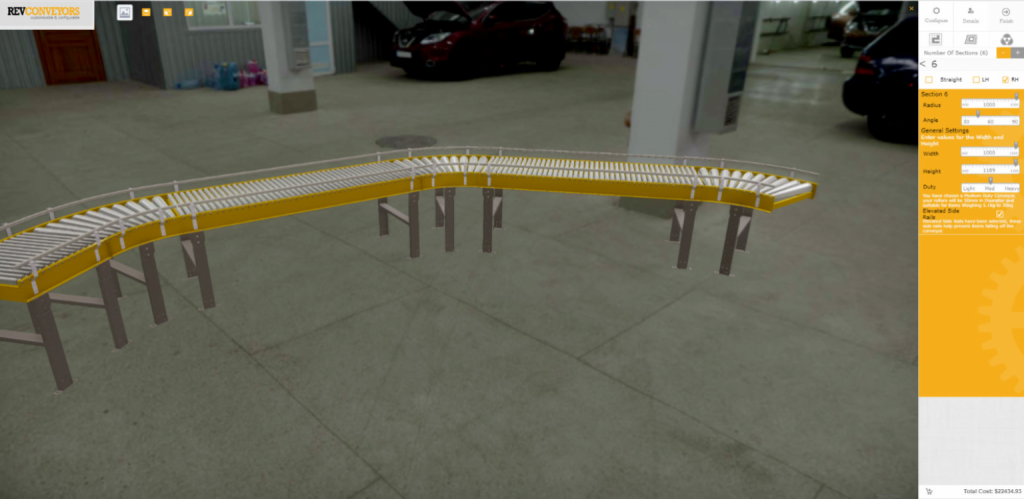

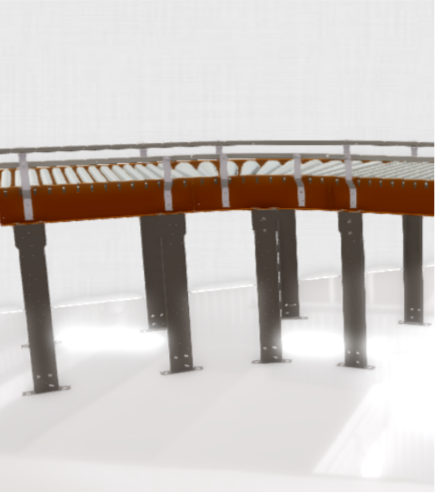

With DriveWorks 18, our team added lots more 3D capability to bring the product to life. The conveyor positioned in a 3D environment has context, just as real-time 3D visual configuration means the effects of the design changes can be viewed almost immediately.

In this example, I’m going to configure a custom conveyor. I’ll choose the number of sections, alter dimensions and angles, and all based on engineering rules and know-how.

With every change I make and every option I select, DriveWorks design automation software is working in the background to update the SOLIDWORKS model on screen, change selections and show an up to date price throughout.

Once I’ve completed my selections, DriveWorks will create all the sales documents and manufacturing details automatically. That includes the SOLIDWORKS 3D parts, assemblies and drawings, BOM and much more.

This automation built into DriveWorks allows for not only a quick turnaround of proposals for the customer, but by automating repetitive tasks it frees up engineering time.

Now, engineering can use the time to innovate, focus and grow other areas of the business.

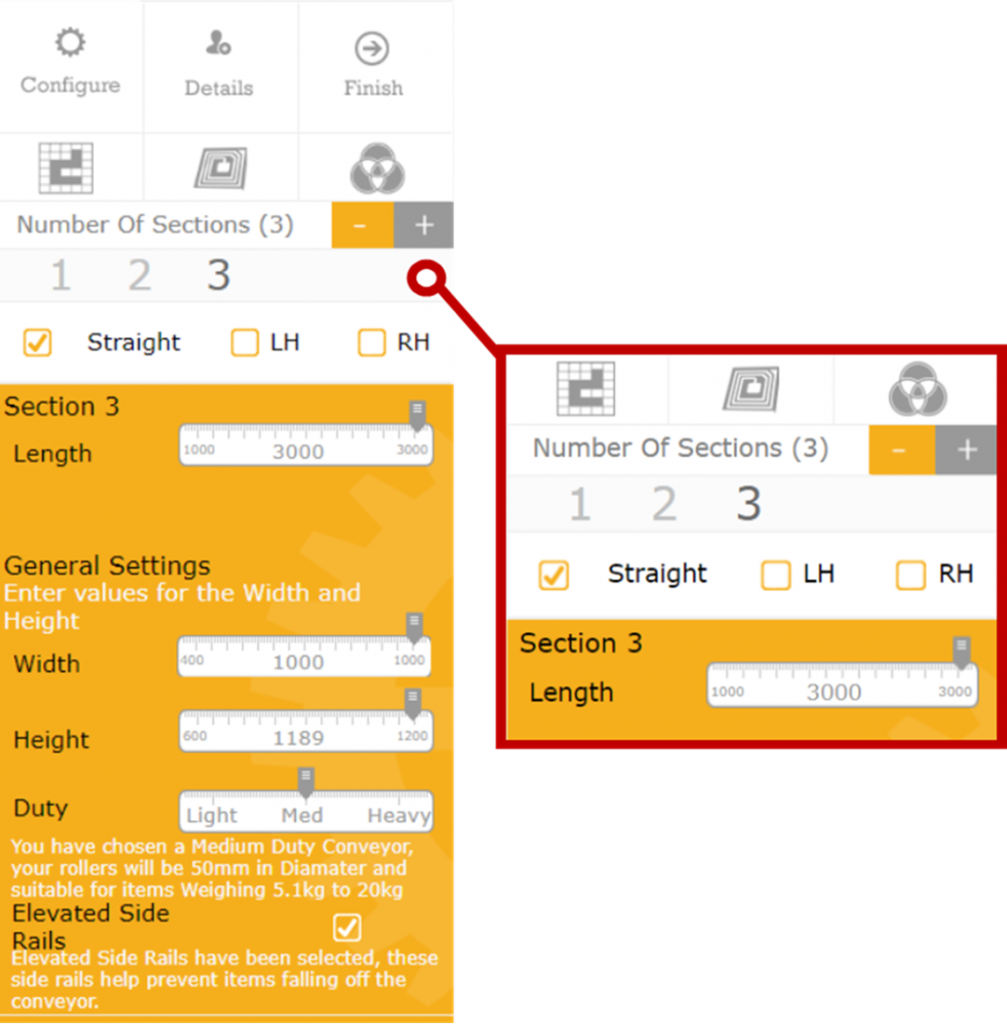

Form Options and Controls

DriveWorks has an in-built form designer which means you can give your Configurator the look and feel that you want. Reflect the colours and styling of your brand and add form controls and options to make configuring your product easy.

In this example, there’s an easy to follow path, that guides us through every step of creating the custom design.

Many controls are available. This example uses out of the box slider controls that have been re-skinned and then used to make it easy to change the values for each conveyor section.

Simple checkboxes allow the user to select different sections types such as straight, right-hand turn, left-hand turn.

The minimum and maximum values on the forms are also driven by rules that have been set in the background.

Rules link the inputs entered on the DriveWorks form to the 3D file and SOLIDWORKS models so that custom designs can be created automatically.

With every change made in this example, we’ve also chosen to display the updated price and the details in the bottom right corner to reflect the latest selections.

Realistic 3D

As we work through this conveyor configurator example, you can see we’ve included different environments to view our model in.

A rule in the background means that a simple click on a checkbox allows us to view the conveyor in either a simple 3D layout form, or in a 3D realistic environment.

When viewing our conveyor system in a 3D environment, being able to rotate the model and move it around the room, helps gives a realistic perspective of the system in situ.

Placing the different conveyor configurations into a real-life space such as this shop floor also provides a more immersive and realistic experience.

3D Perspective

To gain additional 3D perspective of our conveyor, we can zoom, pan and rotate the model while in the online sales configurator.

This can be done by simply clicking on the model and using different mouse commands to move the model.

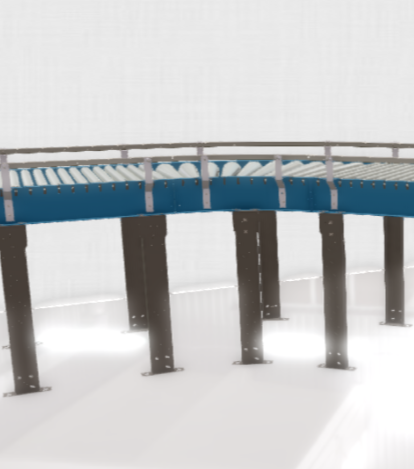

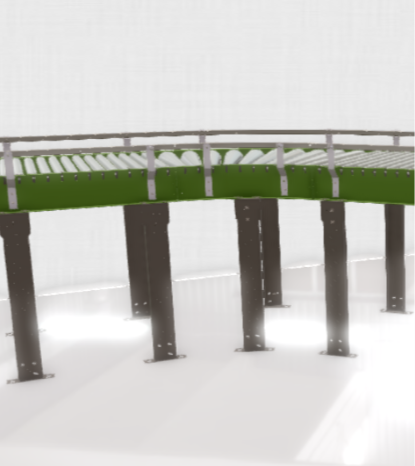

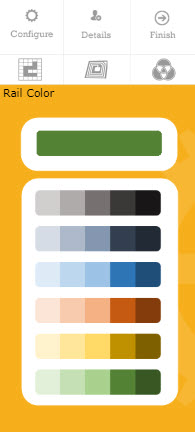

Choosing Colours

Additional design options, such as colour, can be made in the DriveWorks forms as well.

We can change the colour of the conveyor rail system. As the colour is chosen, the change is applied immediately to show how the model will look. These colour changes are powered by the rules that have been built in the background in DriveWorks.

The DriveWorks Form designer provides many options for changing colours. This configurator uses a colour palette to display colour options. This is just one of the ways you can display colour choices on your forms.

DriveWorks has different form control options that let you choose what format suits you. You could use a colour wheel, like in the Cupboard Configurator or a drop-down menu like in the Picture Frame Configurator.

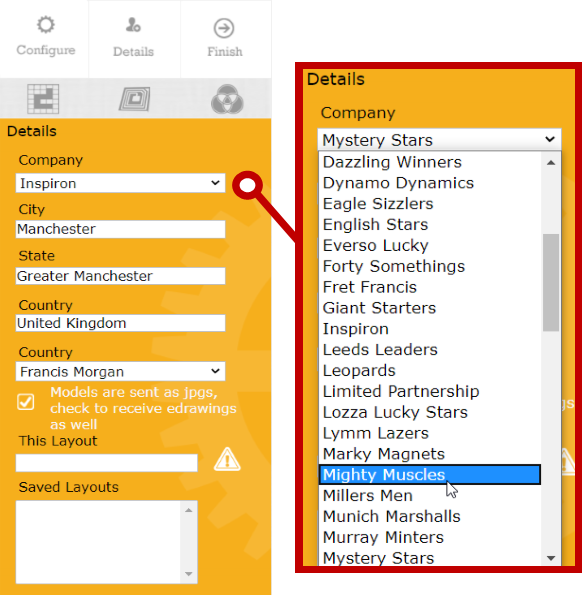

Integration with Business Systems

Once we have configured the conveyor, we can review the order details and customer information before submitting the order for processing.

Customer information can be entered into a text box, or automatically pulled through from other company systems.

DriveWorks can easily pass data to and from your 3rd party systems.

For this example, we see that there are company details listed and we can choose our business.

As DriveWorks is built on its own API, it is very easy to integrate with other business systems (CRM, ERP or otherwise).

Design Automation

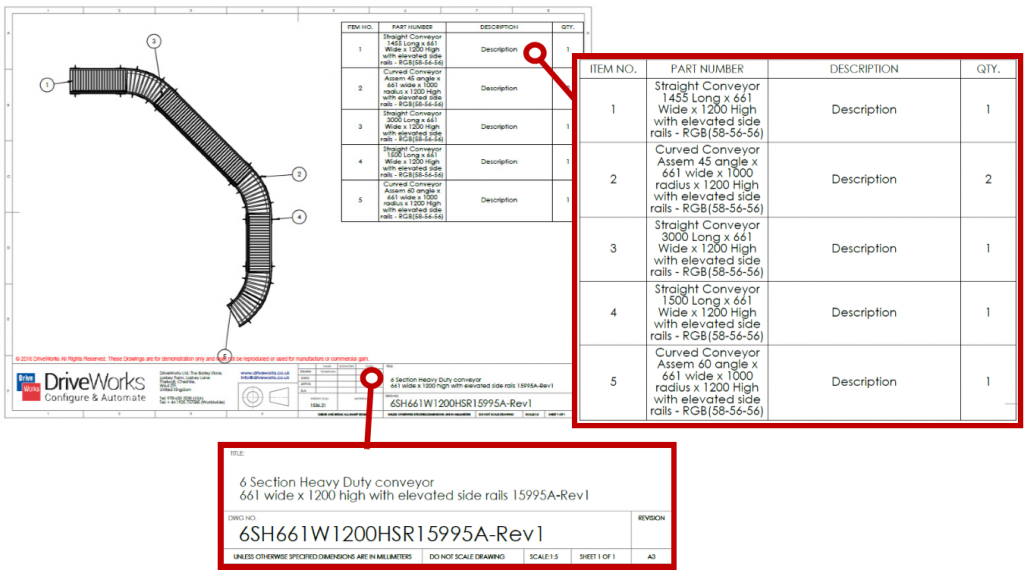

Order-specific models, drawings and documentation are created automatically by DriveWorks.

Once the order is submitted, DriveWorks immediately starts to generate the custom models, drawings, and associated documentation for this conveyor system.

Each document is unique and provides different information specific to the order. We start to receive some of these items via email so we can review them.

While we may receive the sales information, engineering documentation is also being sent.

As DriveWorks is a rules-based system, you can decide what to share and how much to show.

Automated Drawings

In this example, we receive a personalised cover letter, quote, bill of materials and a cut list.

We also receive a fully dimensioned drawing file for the conveyor that we have designed in DriveWorks. You can see on the drawing there are details of the conveyor system along with a description of each section that we designed.

As rules and logic and engineering knowledge have already been entered into DriveWorks, manufacturing of the conveyor can start without engineering needing to check every detail.

The process has been fully automated to reduce errors, improve quality and allow product designers and engineering to focus on innovating and improving.

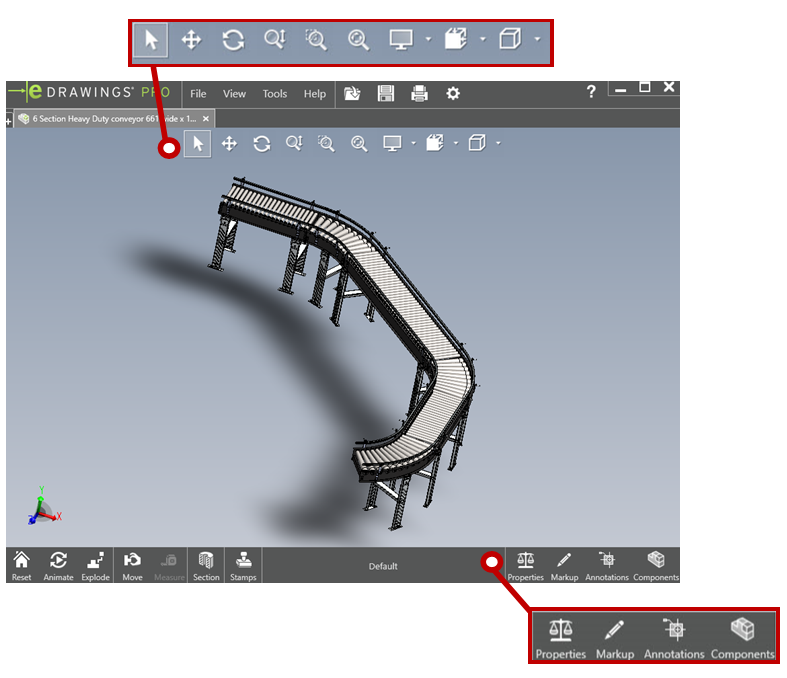

In addition to the SOLIDWORKS drawings, an e-Drawing of the conveyor is generated as well.

This is an example of another file format that can be been generated by DriveWorks. It allows someone that may not have access to SOLIDWORKS to view the model.

Anyone reviewing this can now make comments, annotations, and get views of the model.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This Conveyor Configurator is just another example of how DriveWorks can be used to create a robust 3D online sales configurator and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.