Streamline complex configuration with CPQ for manufacturing

Configuration for custom products can be complex, leading to bottlenecks and errors in design and sales processes. Complex configuration options can be difficult for sales teams to keep track of and require a high degree of engineering involvement. Implementing a CPQ (Configure, Price, Quote) for manufacturing solution optimizes pricing and quoting, enabling businesses to manage complex configurations without compromising accuracy, efficiency, or customer satisfaction.

How CPQ for manufacturing makes complex configurations easy to manage

CPQ solutions enable manufacturers to configure complex products, determine accurate pricing, and generate quotes quickly and efficiently.

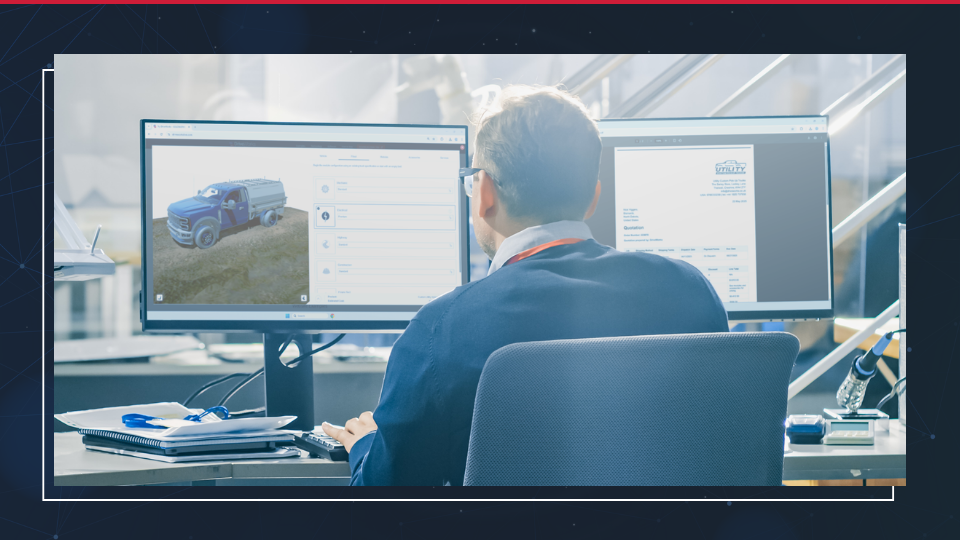

Speed & accuracy in quoting

CPQ automatically generates accurate quotes in minutes so salespeople can configure products, calculate prices, and generate proposals in real-time. Shorter quote cycles lead to improved customer experience and increased sales.

Reduced engineering involvement

By automating repetitive design tasks and freeing up valuable resources, CPQ enables engineers to focus on more strategic and rewarding activities. This not only enhances productivity but also provides more time for engineering innovation and creativity.

Improved customer experience

Guided selling in CPQ uses intelligent rules-based technology to guide customers to make valid configuration choices. Users are provided with information about compatibility issues and receive prompts for suitable alternatives, add-ons, and upgrades.

Scalability

CPQ for manufacturing enables custom manufacturers to scale up their operations to meet the growing needs of their business. Growth across markets or adding more complex product configurations is easy with rules-based technology to ensure quality and consistency.

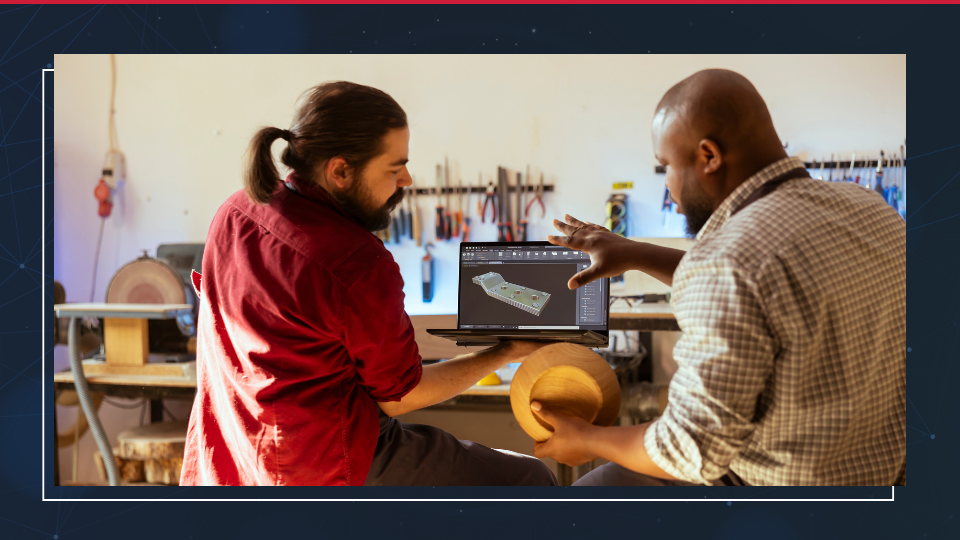

Sales & design team alignment

CPQ for manufacturing enables sales and design team alignment by automating tasks and approval workflows and streamlining communication. Streamlined workflows ensure quotes, designs, manufacturing documents, and data are with the right teams at the right time.

DriveWorks CPQ for Manufacturing in action

DriveWorks CPQ for Manufacturing solution is used by manufacturers from a range of industries. Because DriveWorks technology is modular, scalable, and incredibly versatile, customers use the technology in many different ways, building CPQ solutions to suit the needs of their businesses.

Manufacturers using DriveWorks CPQ for Manufacturing have achieved 50% faster sales onboarding, 95% faster quoting, and a 75% increase in productivity.

Dolphin Solutions, based in the UK, design and supply a range of custom products and accessories for commercial washrooms. Their sales cycle has reduced from days and weeks to minutes and hours with the implementation of DriveWorks CPQ for Manufacturing technology.

“The days and weeks are cut down to minutes and hours, because our customers are finding their final design much quicker. They can see all their options, and the drawings are generated automatically.”

Robert Allen, Product Design Engineer at Dolphin Solutions

Book a CPQ for manufacturing demo with a DriveWorks expert today

Manufacturing custom products doesn’t have to be complicated. DriveWorks CPQ for Manufacturing enables you to make selling easier, reduce errors, and improve efficiency.

Take advantage of the wealth of experience in the DriveWorks team and book a CPQ for manufacturing demo with a DriveWorks expert. They’ll help you get under the hood of different DriveWorks technology features, enabling you to identify and focus on how CPQ can transform your business. They can guide you through practical applications and explain advanced features in a way that enables you to see how the technology could enable you to implement your own DriveWorks CPQ for manufacturing solution.