Configuring a Custom Canopy

Architectural design is one of the many industries already benefitting from the power of an online 3D sales configurator such as DriveWorks.

Providing your customers with the chance to custom create something such as an entrance canopy allows them to take into consideration the unique characteristics of their building as well as their brand.

DriveWorks allows manufacturers to create an online sales tool to not only improve the overall customer experience but to also save time and eliminate redundant engineering tasks.

With automation built into DriveWorks, an online sales configurator provides for quick turnaround on sales proposals as well as eliminating time spent on repetitive tasks and reducing the amount of errors that could be made making constant manual changes to designs.

DriveWorks technology makes selling custom products such as this canopy much quicker and easier and saving valuable engineering time.

We will work through a few quick and easy steps in this custom configurator to design the canopy. By utilizing Interactive DriveWorks Form Controls we will be able to make changes to the design of the canopy easily.

We soon see how easy it is to design this product in DriveWorks and get a full set of engineering drawings when our configuration is complete, and order submitted.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom canopy online.

Realistic and Interactive 3D

With DriveWorks 19, our team have added lots more 3D capability to bring the model to life. We’ve positioned the canopy in a scene to give it context and a more realistic feel.

I’m going to step through a series of options to specify the size of my canopy. I have the ability to choose dimensions as well as construction components and colours.

With every change I make and every option I select, DriveWorks software is working in the background to update the model on screen, update selections and show an up to date price throughout. Once I’ve completed my selections, DriveWorks will create all the manufacturing details automatically. That includes the SOLIDWORKS 3D parts, assemblies and drawings, cut lists, BOM and much more.

The entrance canopy is situated in a 3D environment to give the customer a realistic perspective.

By adding things such as shadows, contrasts, and other attributes such as lighting effects and textures the model is not only visually appealing but also brings a realism to the experience for the customer.

In addition to the 3D attributes, DriveWorks allows the user to pan and zoom and rotate around a bit in the 3D environment to get a better feel for how the canopy may look in place.

Currency Choice

Form controls and rules built into DriveWorks let the user choose the currency they wish to work in as part of their order.

Manual and time-consuming conversions are no longer needed because this work is being done quickly and accurately in the background, by DriveWorks.

By choosing a currency, the calculations throughout the process will update in the appropriate currency.

This is a great feature to add to your configurator if you host an international customer base and need to work in different currencies.

Choosing Dimensions, Support and Color

As with other DriveWorks configurator examples we have seen, we once again can use DriveWorks Form technology to design our canopy.

As forms are the primary user interface of your configurator, they should work well for the customer as well as make sure they capture what’s needed for the design.

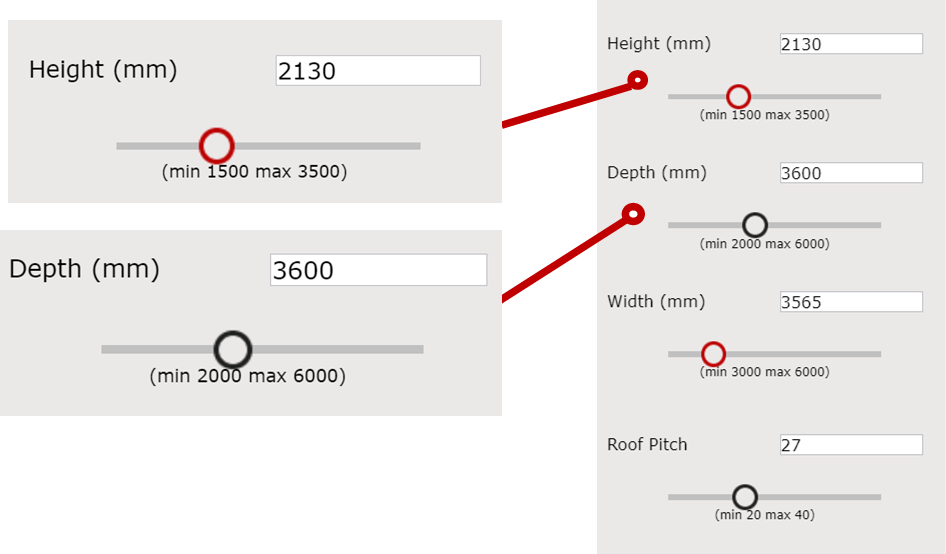

Using these form controls, we can choose the dimensions of the canopy.

The forms offer both the use of the slider tool or a text box to input our required dimensions.

Rules built in the background control and guide our inputs and once changes are made on the form, the model is updated right away.

DriveWorks has fully automated SOLIDWORKS so the models and drawings are both updated. The price is also updated as changes are made.

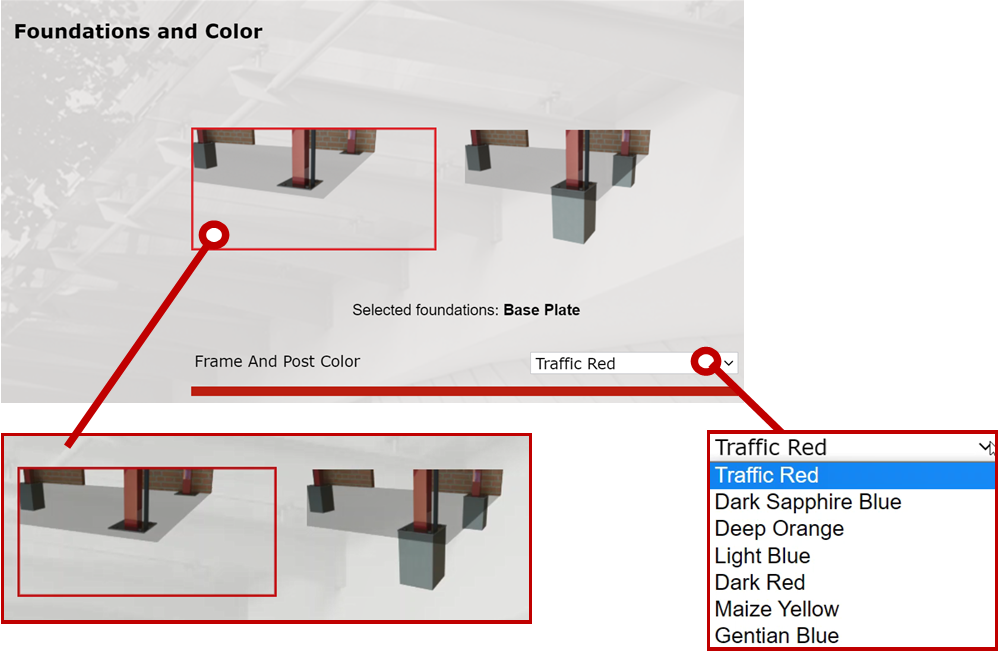

In addition to the dimensions, we also choose different foundation footings as well as colors for the canopy.

There are several ‘out of the box’ options available for forms in DriveWorks. In this example, a picture box is used to select the foundation footings and for color choice there is a drop-down menu.

All these forms have rules built into the background that drive the changes to be made to the model.

In addition to the out of the box form controls, there are also custom and styled form controls created that meet the needs of your business.

As we complete the design of the canopy, we have a few more items that need our attention.

We have some add-on options that relate to the sale, service, and installation of the canopy.

Remember – this is your chance to not only provide the customer with a complete experience but also to sell your product!

Again, with simple DriveWorks forms in place, simple check boxes are available for the customer to choose what they would like to add onto their order.

These changes are added to the order and quote is adjusted based upon our inputs.

Results Page

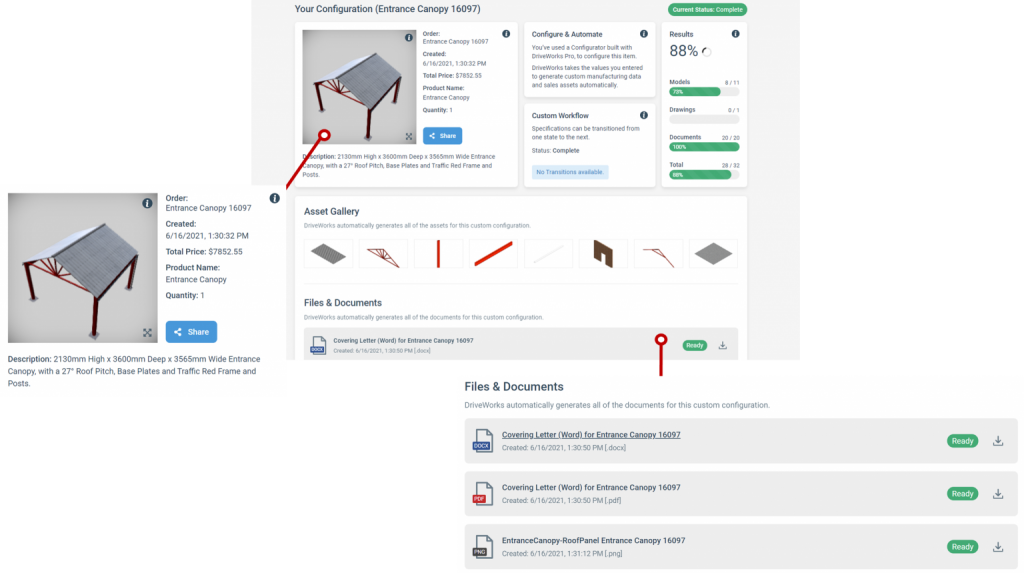

Once we click submit the configurator takes us through to the Results Page. Here we can view and access all of the files, documents and other digital assets generated by DriveWorks. In an easy to view window, we can see the details of the order including price, order name & number, the date it was created and a full description of the order.

You can click through and view all of the assets DriveWorks automatically generates for this custom configuration. Click through the asset gallery to view each individual asset in turn.

On this page, you can also view and download all of the files and documentation automatically generated for this order including:

•Manufacturing Data

•Sales Documentation

•Data Outputs

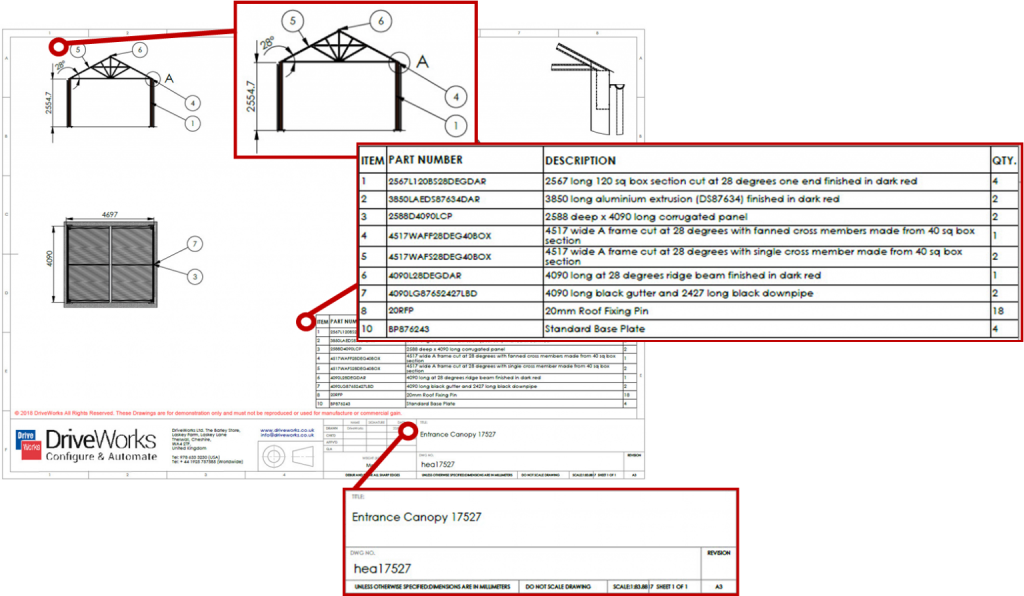

Once we have submitted the order, DriveWorks automatically generates an order confirmation as well as the quote and bill of materials.

Each document is unique and provides the customer with information specific to their order.

As you control what the customer receives through the rules-based workflow created in DriveWorks, you can include your logo, branding and any other messaging you wish to send the customer as part of this process.

For manufacturing, it is a huge time saving to have the CAD models and associated drawings automatically created with DriveWorks.

Having the manufacturing information automatically created not only saves time on repetitive design, it also helps reduce errors and decreases time to market, giving you a competitive edge over your competition.

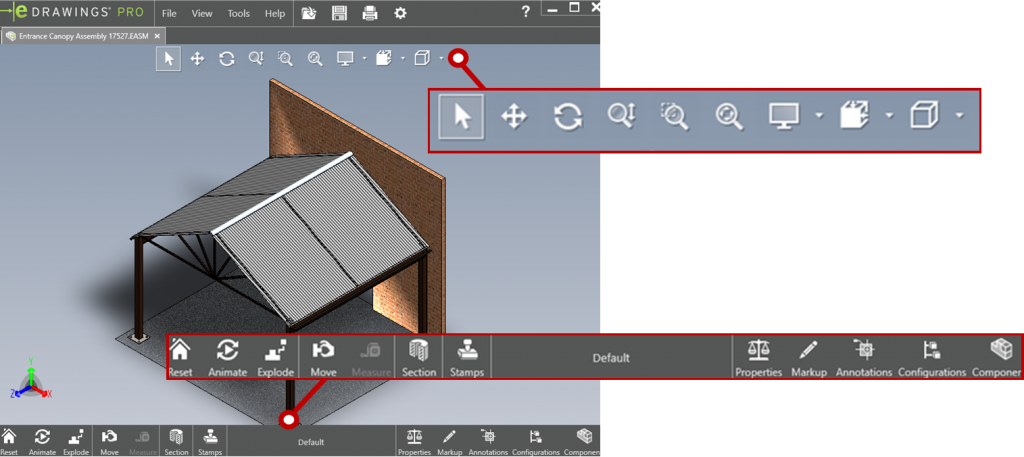

Additionally, DriveWorks generates an eDrawing of the assembly as another way to allow for quick viewing and approval.

DriveWorks technology is in use from start to finish when configuring this entrance canopy. Starting with the form controls in place to capture dimensions and basic design inputs, to the rules that have been created to drive the models, there is a lot going on in the background yet it’s seamless to the customer. When the product design and knowledge is captured in DriveWorks, the data required to create new versions of the product is generated quickly and accurately. It then ties into sales, engineering and then on to manufacturing.

Creating sales documentation for the customer as well as manufacturing documentation gives you a huge advantage in quality of design, cost savings and by reducing time to market.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This canopy configurator is just one example of how DriveWorks can be used and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.