How CPQ improves accuracy in custom manufacturing

Configure, price, and quote custom products faster and with greater accuracy.

Error rates in custom manufacturing can often be high. Complex configurations are difficult to sell accurately, with the sheer volume of product options requiring detailed product knowledge. Configuration errors lead to increased rework and re-quote volumes, slowing down the quoting and sales process. Increased pressure on sales, engineering, and production teams makes workflows inefficient.

Custom manufacturers use CPQ to automate complex configuration and pricing, reduce the level of manual input, and improve accuracy levels.

Reducing errors with CPQ

Using pre-defined logic, CPQ ensures every configuration, price, and quote is accurate. For manufacturers of complex custom products, CPQ eliminates configuration errors, applies pricing rules, automates quoting, aligns team efforts, and delivers accurate data insights.

1. Eliminates configuration errors

Complex custom products can often have hundreds, or sometimes thousands, of different variations, making it difficult to guarantee accurate configurations.

With guided selling functionality in CPQ, sales teams build configurations with ease, selecting product features from a set of pre-determined manufacturable options. Therefore, only feasible configurations are selected.

This ensures accuracy and speeds up the sales cycle.

2. Ensures consistent pricing

Manual pricing for custom products often involves working with large amounts of spreadsheet data. The risk of human error is high, and ensuring data is up to date can be challenging.

CPQ automatically applies pricing rules and discounts, ensuring prices are accurate and reflect current business pricing strategies.

Consistent pricing ensures accurate quotes, improves sales, and maximizes profit margins.

3. Speeds up quoting

The risk of quote errors is high with manual sales processes for custom products. Slow quote cycles impact sales volumes and customer satisfaction.

CPQ automatically calculates prices, including any discounts, and generates accurate, professional-looking quote documents instantly based on configuration choices.

This eliminates manual data entry and speeds up quote cycles.

4. Aligns sales, engineering, and production

Workflows for custom products involve lots of communication between sales, engineering, and production teams. Ensuring all teams are aligned is challenging with different groups working on separate workflows, and miscommunication causing bottlenecks and rework.

CPQ streamlines workflows and automates approvals, enabling a smoother flow of dialogue and data. At the same time, teams can work together efficiently and cohesively.

5. Improves data accuracy

Inaccurate quotes and sales data make it difficult to analyze product demand and sales metrics. Incorrect data can lead to mistakes in forecasting and challenges for effective business analysis.

CPQ captures every configuration and pricing action accurately, and integration with other business systems, such as ERP and CRM, ensures company-wide data accuracy.

Accurate data enables informed decision-making and effective sales forecasting.

Using DriveWorks has helped us automate design processes to free up valuable design team resources, and provides our customers with quick, professional and accurate quotations for our acoustic solutions.

Dwane Brown, Group Technology Manager at Autex

Introduction to creating a CPQ solution using DriveWorks

Tuesday, 25th November, 1pm – 2pm AEDT and 3pm – 4pm GMT

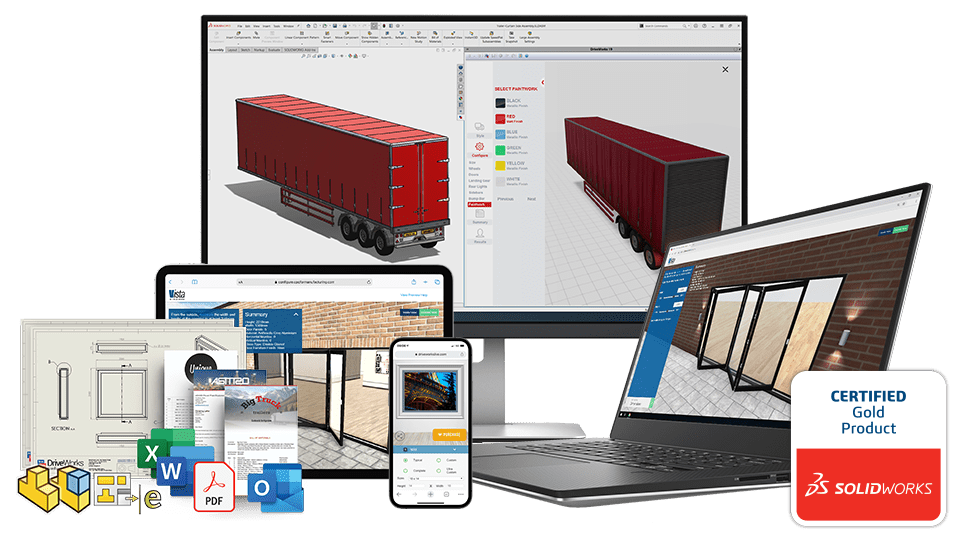

DriveWorks combines powerful SOLIDWORKS® part, assembly, and drawing automation with engaging 3D CPQ sales configurator features to enable manufacturers to implement a successful digital selling strategy, work smarter, reduce errors, and exceed customer expectations.

In this webinar, our product experts will share their knowledge of creating a CPQ solution using DriveWorks.

We run this webinar twice for users around the world. Choose the session that works best for you.

Tuesday 25th November, 1pm-2pm AEDT

Tuesday 25th November, 3pm-4pm GMT