Manufacturing bottlenecks directly impact revenue. However, by implementing a digital transformation, you can minimize their impact and maximize your profit.

This blog, written by DriveWorks Reseller GoEngineer looks at those common bottlenecks and how you can use DriveWorks to fix them.

Welcome to the world of modern manufacturing, where precision and efficiency are the name of the game. In this blog, we’ll look at the challenges that can disrupt the smooth flow of production, affecting timelines, costs, and overall operations.

These challenges are often referred to as bottlenecks—critical points in the process where things slow down or get stuck. We’ll unravel these bottlenecks, from the complexities of rework to the intricacies of quoting practices. And we’ll also shed light on how a digital transformation, facilitated by tools like DriveWorks, can help streamline these processes.

Imagine a system that connects all the dots, ensuring that sales orders seamlessly integrate with your ERP, instantly and accurately capturing customer demands. This is the power of digital manufacturing, and it has significant potential to revolutionize the manufacturing landscape.

Bottleneck #1: Rework

The Problem with Rework

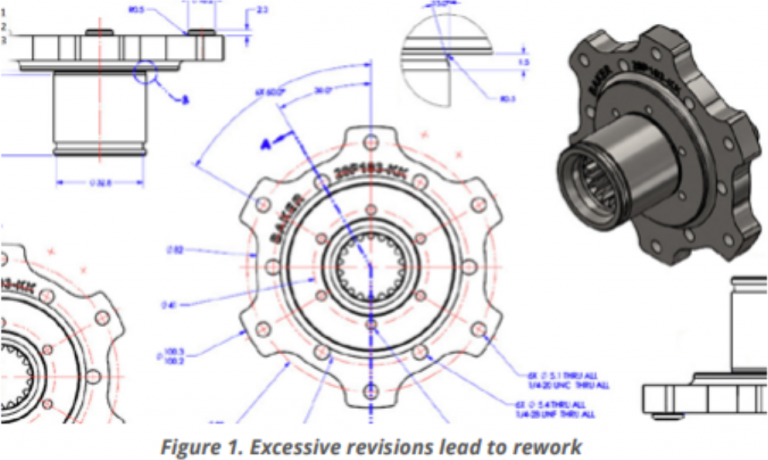

The cost of rework isn’t just the materials; it encompasses the time spent addressing customer concerns, the opportunities lost by delaying other projects, and a range of other implications. Each project leaving the production line must meet high standards, as any imperfections directly impact the bottom line. Poorly implemented quality control processes, a lack of communication between departments, and human error are among the countless potential causes of rework. To address this, a strategic approach involves integrating design automation tools like DriveWorks, as part of a broader digital transformation strategy.

How to Measure Rework

One essential metric to gauge the cost of rework is First Pass Yield, also known as throughput yield. This measures the proportion of flawless units produced compared to the total units initiated in the process. For instance, if the goal was to manufacture 100 units and 97 emerge from the process flawlessly, the First Pass Yield is 97%.

How DriveWorks Reduces the Need for Rework

Although reaching 100% is often unattainable, integrating design automation tools like DriveWorks early in the production process significantly improves the consistency of product flow. Instead of relying on manual calculations and data entry, DriveWorks applies the same equations, the same way, every time – giving you dependable results. By doing so, you reduce the chance of human error and increase the likelihood of consistently achieving the desired product, ultimately lowering the costs and efforts associated with rework.

Bottleneck #2: Inconsistent Quoting

The Problem with Inconsistent Quoting

Ensuring a streamlined and consistent quoting process is vital for timely product deliveries. Ideally, clients could furnish all necessary information upfront, swiftly receiving an accurate quote within moments. However, reality often demands us to explore alternatives and imperfect estimations.

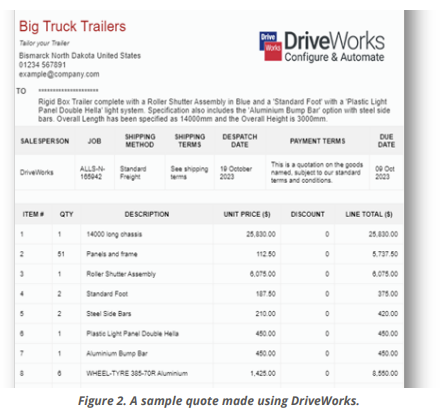

Conceptualizing a Consistent Quoting Process

When envisioning an effective quoting process, uniformity is key. Each person creating a quote should pose standardized questions in a consistent format. Simultaneously, customers should respond in a structured manner, ensuring thoroughness and clarity. An informed decision-making process for customers would involve visual aids, agreed-upon terms, and a clear expected delivery date.

Designing a tool or process encompassing these attributes requires an investment of time. Yet, the rationale behind such an endeavour is obvious. This transformation represents a move towards a standardized quoting system, minimizing unnecessary touchpoints between the customer and the manufacturer.

How DriveWorks Adds Consistency to Quoting

DriveWorks emerges as a game-changer in this scenario, offering an open canvas for reimagining the quoting process. This innovative tool not only facilitates consistent quoting but also empowers organizations to craft a seamless journey for quotes, ensuring efficiency from the client’s initial inquiry to the final manufacturing stages.

By tying the sales process directly to manufacturing, you can ensure customers only see manufacturable designs. This leads to an accurate picture of your product offerings and increases customer satisfaction. Adding on, DriveWorks uses the same template for every document and all information used to create said quote comes from a uniform source. By pulling pricing from the master location, you ensure every quote that leaves your hands is accurate and timely.

Bottleneck #3: Retraining

The Problem with Retraining

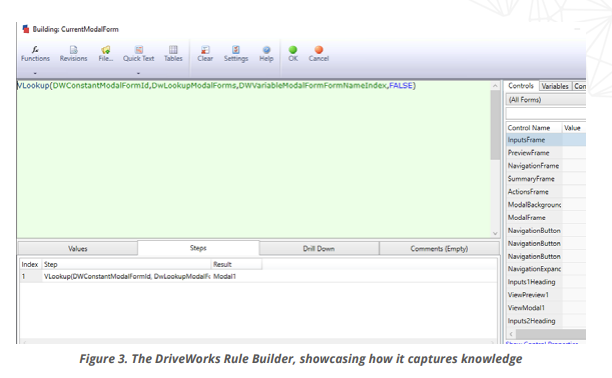

In the realm of manufacturing, the impact of a digital transformation on retraining is profound and multifaceted. The departure of an employee often creates significant bottlenecks within a manufacturing process, especially when accompanied by the loss of specialized or “tribal” knowledge. Traditional retraining to bridge this knowledge gap can be time-consuming and costly, hindering overall productivity.

However, a strategic digital transformation, utilizing automation tools like DriveWorks, can remarkably mitigate this bottleneck. By digitizing and centralizing critical knowledge and workflows, these platforms allow for efficient knowledge capture and dissemination. This includes transferring the expertise of departing employees into systems that can be accessed and utilized by a broader range of employees and external stakeholders. Essentially, it transforms “tribal knowledge” into a structured and accessible digital format, reducing the time and resources required for retraining.

What Retraining Looks Like After a Digital Transformation

A digital transformation enables the creation of intuitive, automated systems that systematically guide employees through complex tasks. This not only accelerates the retraining process but also standardizes procedures, ensuring consistency and quality across the manufacturing process. The democratization of information facilitated by digital tools means that employees can access the right knowledge precisely when they need it, promoting a culture of continuous learning and adaptability within the organization.

How DriveWorks Propels You Forward in the Face of Turnover

By converting tacit knowledge into explicit digital resources and automating key aspects of workflow, manufacturers can effectively overcome the bottleneck created by employee turnover and changes, ultimately propelling the industry forward. Explicit documentation of your processes and methodologies enables a shallow learning curve and a more robust system in the face of change.

In essence, a digital transformation, particularly with tools like DriveWorks, plays a pivotal role in streamlining retraining processes, significantly improving the overall agility, efficiency, and resilience of manufacturing operations.

Bottleneck #4: Customer Wants to See it First

Why “Seeing It First” is Hard

There’s a level of comfort that people get from seeing what they’re going to buy before they buy it. This is true for nearly any industry – buying a car, buying groceries, booking a vacation. No matter what it is, customers gain peace of mind because “seeing is believing”. The same is true in manufacturing.

The problem lies in how different industries fulfill orders. In a “build-to-order” or “assembly-to-order” business model, this may mean designing a new product before receiving a promise to purchase from the customer. Not only is this risky, but this is potentially costly due to the rework problem discussed previously.

What A Digital Transformation Means for First Impressions

By undergoing a digital transformation and embracing tools like DriveWorks, you empower your customers with digital product catalogs and detailed renderings to assist in product visualization.

How DriveWorks Improved the Buyer’s Experience

It keeps your costs down while augmenting your customers’ buying experience. Because it allows them to try an endless series of combinations, customers can better understand what they’re buying and will value the experience you provide via a digital transformation.

A configurator brings the necessary information to the user’s fingertips. By providing every potential combination of selections, a customer can get a fuller picture of how your products will fit their needs. Additionally, the prospect of guided selling increases pipeline visibility, accelerating your sales cycle and removing potential missteps.

Bottleneck #5: Inadequate Resource Planning

The Problems Caused by Inadequate Resource Planning

Inadequate planning poses a significant challenge in manufacturing operations, impacting production timelines, customer satisfaction, and ultimately the bottom line. The crux of this issue often lies in inaccurate or incomplete lead time calculations and the inability to provide reliable availability of critical items based on inventory.

Manufacturers grapple with the complexities of estimating lead times for various components, materials, and finished products. While an inventory management system is a great tool, it may not be linked directly to the quoting and design system.

How Does Ideal Resource Planning Affect Production?

When these estimations fall short of reality, they disrupt production schedules and can lead to costly delays. Additionally, maintaining an optimal inventory level is a delicate balance – too much can tie up resources and capital, while too little can halt production or lead to missed opportunities.

Implementing DriveWorks Improves Resource Planning

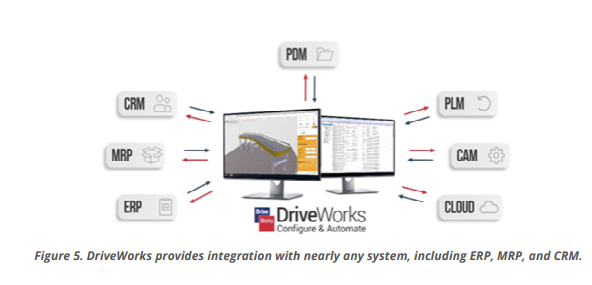

One powerful solution to tackle this challenge lies in embracing a digital transformation within manufacturing processes. By incorporating advanced tools like DriveWorks, manufacturers can revolutionize their inventory planning approach. Design automation and digital systems can provide real-time insights into inventory levels, supplier lead times, and production capacity.

This data empowers manufacturers to make informed decisions, ensuring accurate availability of items, and precise lead time calculations, thereby optimizing inventory management, and improving overall operational efficiency.

Conclusion

Maximizing revenue is all about minimizing bottlenecks. Any chance you have to remove rework, standardize quoting, and minimize retraining should be capitalized on. Additionally, giving your customers peace of mind in their purchase without expensive prototypes is key to increasing sales without an increase in up-front work by your engineering team.

A digital transformation ties your systems together. This gives you a clearer picture of the resources you need and how to best plan ahead. By automating your processes with DriveWorks, you get your entire team on board and maximize the work they provide on value-add activities.

Tailor digital strategies to work for you

There are many reasons why you may be planning a digital transformation strategy – you might want to fix a bottleneck, you might want to dedicate more time to research and development or you might be looking to set your company apart from competitors. Whatever your challenges are, and whatever your goal is, it’s important to make sure the digital technologies you implement work for your organization. Whilst you don’t need to do everything all at once – it is still important to think about your potential future needs when choosing your digital tools.

For more information about GoEngineer, visit: www.goengineer.com