For DriveWorks World 2025, we introduced a new feature, designed to showcase our technology and the expertise of our team. The DriveWorks World 2025 live implementation was a real-time implementation that members of the DriveWorks team worked on throughout the event. They joined us live in the DriveWorks World studio at different points in their implementation process to share their progress and discuss how and why they had implemented specific features and functionality.

Throughout the implementation, DriveWorks World attendees had the opportunity to influence the direction of the work by taking part in polls to determine the actions the team took. Using the DriveWorks World event app, they were also able to put questions to the team directly to get their feedback and insight.

In our May Tech Talk on 15th May, we’ll catch up with the live implementation team and learn about the progress they have made since DriveWorks World, and what their next steps are.

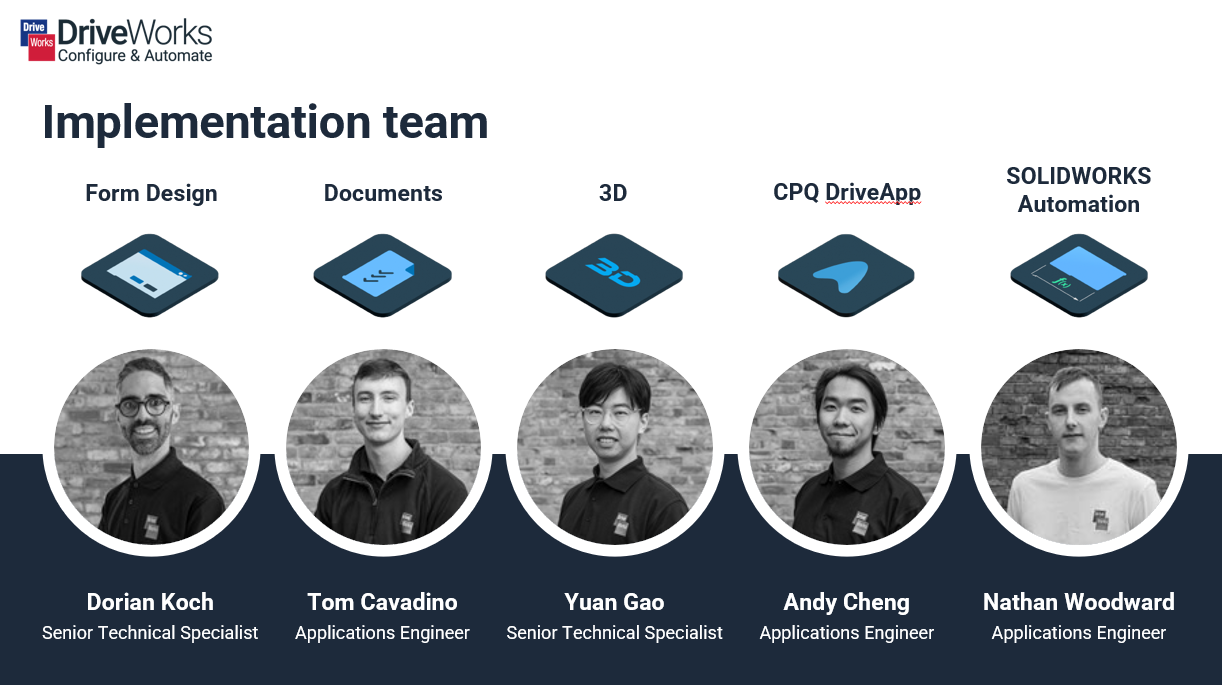

The live implementation team

The live implementation team worked collaboratively across two locations, with Dorian Koch, DriveWorks Senior Technical Specialist, working from his base in France, and other team members working from DriveWorks HQ.

Each team member worked on a different part of the implementation, using their DriveWorks expertise on either forms, documents, 3D, CPQ DriveApp, or SOLIDWORKS automation.

The team joined us live in the studio to share their progress and discuss how and why they have implemented specific features and functionality. At the final check-in, DriveWorks Key Account Manager & Implementation Consultant, Phil Gilbanks, shared the finished configurator with the DriveWorks World audience, with the implementation team also joining from implementation HQ, and Dorian joining from France.

The implementation brief

The team was given the task of building an online 3D configurator solution for a fictitious gate company – Manor Premium Electric Gates.

Gates are often highly customized products with customers configuring bespoke products to fit their needs. Configurations can vary based on multiple criteria, such as style, size, color, finish, material, etc.

Online gate configuration is also a process that benefits from 3D visualization, enabling the implementation team to showcase DriveWorks UI and 3D functionality.

The team followed the tips that had been shared in an earlier live stream on the best practices that make companies implementing DriveWorks successful and profitable.

Implementation direction surveys

We wanted this to be an interactive implementation, so we gave DriveWorks World 2025 attendees the opportunity to influence how the implementation was built. Through a series of polls launched in the DriveWorks World 2025 event app, attendees voted for the functionality they would like to see included in the implementation as it progressed.

The outcomes of the implementation direction polls led the team to focus on the DriveWorks features and functionality attendees wanted to learn more about. It provided an opportunity for the implementation team to showcase DriveWorks technology and show how it can be used in a realistic scenario.

Form UI

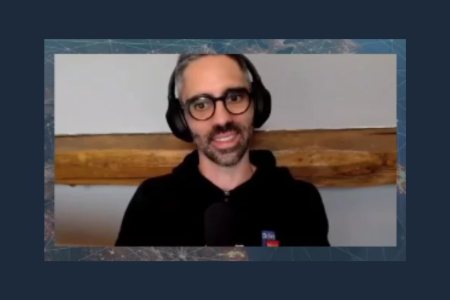

DriveWorks Senior Technical Specialist, Dorian Koch focused on building the configurator forms and incorporating best practice UI.

During his live implementation check-in, Dorian shared his insight on using pre-designed layouts for consistency, ensuring the flow of the forms is logical and user-friendly, simplifying the user experience by reducing unnecessary fields, and the most voted for feature – creating search functionality.

He used a white-label project template to:

- Speed up development

- Provide a consistent and professional design foundation

- Take advantage of ready-to-use layout patterns

- Help focus on functionality and user experience

He also shared how designing the navigation structure, with flow charts or wire frames to help with visualization, ensures you have clarity before starting your UI design.

Documents

DriveWorks Applications Engineer, Tom Cavadino, worked on the output documents of the implementation.

During his live check-in, he shared how he had created 2 final documents:

- Quote document with pricing information & 3D images

- Manufacturing pack with a BOM, weldment cut list, and drawings

Documents were created using markdown text documents & specification macro tasks. Tom also covered the most voted for feature – getting data from SOLIDWORKS modules into documents.

3D

DriveWorks Senior Technical Specialist, Yuan Gao, worked on the 3D functionality of the configurator.

During his live check-in he covered:

- 3D document structure (the most voted for feature)

- 3D extrusion

- PBR (Physical Based Rendering) appearance

He shared 3D functionality, including animation transitions, enabling users to see the gates opening and closing, and switch between night-time and daytime views.

He shared the node structure that he’d developed using document replacers, polygon functions, and extrusions to deliver a highly responsive and scalable 3D solution.

CPQ DriveApp

DriveWorks Applications Engineer, Andy Cheng, worked on the CPQ DriveApp functionality.

The most voted feature for this functionality was data synchronization. DriveWorks Product Manager – CPQ, Tom Wormald, shared his insight on the data sync tool in the DriveApp. Using the tool enables you to sync accounts, contacts, and items (including files and pricing) directly into the DriveApp database.

He also shared how Andy had used a project template to map fields in a third-party system to the CPQ DriveApp.

The UI on the DriveApp was also customized to match the Manor UI and branding.

SOLIDWORKS automation

DriveWorks Applications Engineer, Nathan Woodward, worked on the SOLIDWORKS automation functionality of the gate configurator.

Nathan explained the value in taking time at the start of your implementation to think about what you want to automate.

He shared his insight on the most voted for feature – using Generation Tasks to insert components and create mates, and using a calculation table as a “single source of truth” for all of the gate variables.

He also showed how he used multiple component sets from one specification and how he used configuration-specific dimensions.

Explore the Manor gate configurator

The product configurator examples on driveworkslive.com are a great way to see what’s possible with DriveWorks software in a range of different scenarios. They enable you to get hands-on and see what it is like to use a configurator built using DriveWorks software, and take your website and online sales to the next level.

DriveWorks product configurator software is used by companies of all sizes. It’s suitable for any industry where quotes or 3D files, and drawings are part of the sales to manufacturing process. Our configurator examples show how versatile and customizable DriveWorks is and provide great inspiration for your DriveWorks projects. DriveWorks software is not limited to what you see in our examples, our technology enables you to build a custom solution that suits your needs and is easy to maintain and update

We’ve embedded the finished Manor gate configurator on driveworkslive.com so you can see the output of the implementation and try it out for yourself.

May Tech Talks: DriveWorks World 2025 live implementation recap

Tech Talks webinars provide an opportunity to learn directly from DriveWorks experts, sharing valuable insights and technical tips to help you extend your knowledge, get the most out of your software and learn how you can improve your DriveWorks implementation.

In this Tech Talks, we’ll be catching up with the live implementation team, getting a reminder of the work they did during DriveWorks World, seeing the progress they have made since the event, and finding out what their next steps are.

This webinar is exclusively for DriveWorks Pro Customers with Subscription, DriveWorks Resellers and Authorized Partners.