Industry Spotlight

Medical

Overcoming industry challenges

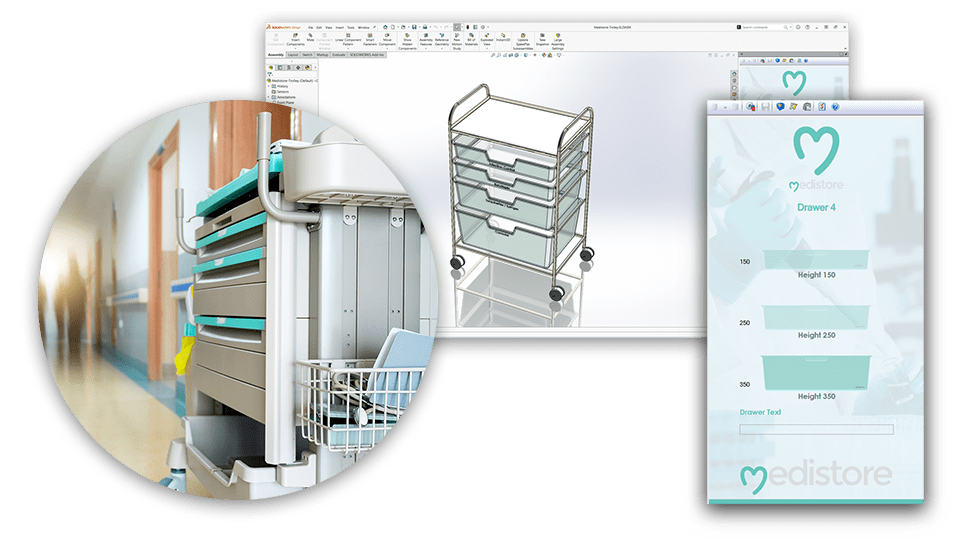

DriveWorks design automation, 3D configurator, and CPQ solutions streamline design engineering workflows, ensure quality, and speed up design and sales cycles for custom medical equipment products.

Customization

Medical equipment manufacturing includes a wide range of products, from hospital equipment such as patient beds and diagnostic machines to dental equipment and surgical instruments. Customization can be complex, with equipment designed to meet specific patient requirements.

How DriveWorks helps

DriveWorks enables customization without additional engineering workload. Custom models, drawings, and BOMs are generated automatically, saving engineering time and ensuring accuracy.

Configuration rules prevent incompatible options, ensuring all specifications are accurate. This reduces rework volumes and improves customer satisfaction.

Regulatory compliance

Regulatory compliance in medical equipment manufacturing is crucial for ensuring patient safety and quality of care.

Compliance with regulations enables healthcare providers to foster trust with their patients. Reliable delivery of compliant medical equipment is also key for manufacturers to build trust with their customers.

How DriveWorks helps

DriveWorks ensures that every configuration follows engineering rules and parameters, guaranteeing accuracy. Drawings and BOMs match customer specifications, and models and drawings are generated consistently.

Guided selling enables sales teams to accurately configure complex enclosure configurations without the need for extensive product knowledge or training.

Error-free engineering

Error-free engineering is key to ensuring medical equipment quality, safety, and reliability while significantly reducing costs and waste.

How DriveWorks helps

DriveWorks automates medical equipment design by embedding rules, enforcing standards, validating inputs, and eliminating manual errors.

Medical equipment manufacturers use DriveWorks to deliver consistent, high-quality, and compliant product configurations, drawings, and BOMs.

Engineers have more time to focus on product development, leading to improved job satisfaction and a culture of product innovation.

Customer Success Story

Learn how Monmouth Scientific have improved customer experience and streamlined their sales cycle with DriveWorks.

Get started with DriveWorks

Getting started with DriveWorks is quick and easy.

Get started for free

DriveWorksXpress is free inside SOLIDWORKS and you can try DriveWorks Solo free for 30 days.

Explore solutions

Learn more about how the features in DriveWorks can be utilized.

Compare software

Compare the features in DriveWorksXpress, DriveWorks Solo, and DriveWorks Pro.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.