Rademaker

Rademaker reduces engineering time to 15 minutes and increases quality by automatically creating SOLIDWORKS® models and drawings with DriveWorks.

Challenge

Rademaker needed a solution to save engineering time by automating the creation of SOLIDWORKS drawings. They also wanted to integrate with their existing SAP Product Lifecycle Management (PLM) system to streamline company processes.

Solution

Implemented DriveWorks Pro as a product configurator and SOLIDWORKS automation solution to optimize engineering processes. Rademaker integrated DriveWorks with SAP using native SQL integration.

Results

Engineering time was reduced to less than 15 minutes for modular units and a 30% reduction in time was achieved using standardisation. Integration with SAP has increased production process efficiency and improved quality.

Company overview

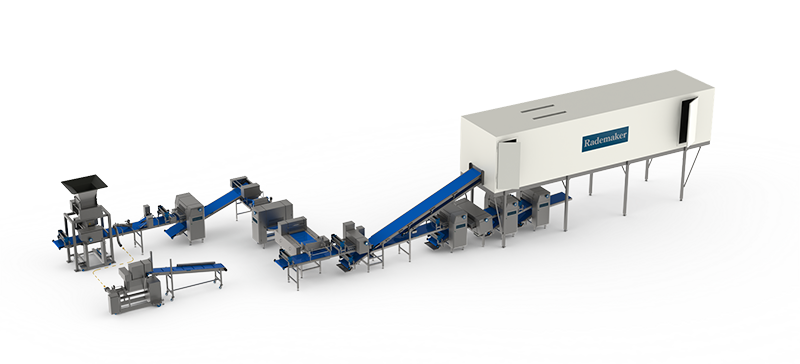

Rademaker have over 40 years of experience providing solutions for the food processing industry. Their broad portfolio of production lines includes bread, laminated dough, croissants, pastry, pies, and pizza. The Rademaker brand is recognized across the globe for its knowledge and experience in automation, engineering, and hygiene.

Challenge

Substantial engineering time

Previously, the engineering time required to prepare an order for manufacturing was substantial. SOLIDWORKS models had to be manually updated to create the production drawings and bills of materials (BOM).

Rademaker identified the need for a product configurator and SOLIDWORKS automation solution to optimize their engineering processes. They wanted the ability to fill out the specifications of a machine and have the 3D models, drawings, and BOMs automatically generated.

Integration with SAP PLM

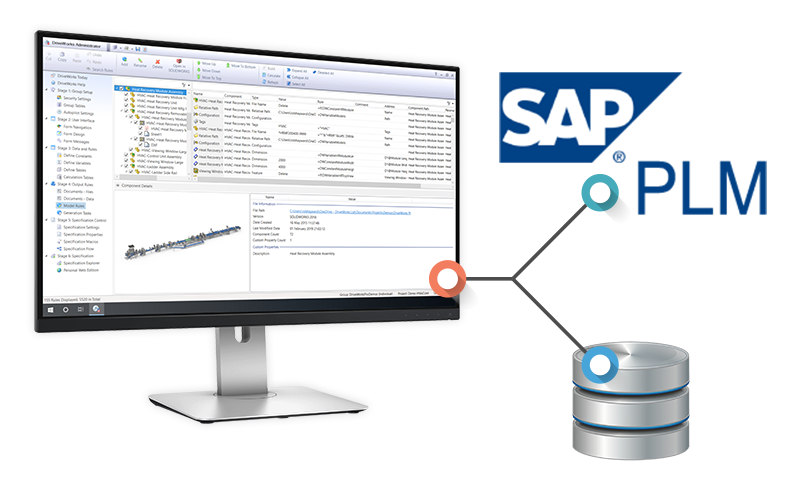

Rademaker also wanted to increase production process efficiency and achieve a higher level of quality by integrating the new solution with SAP-PLM.

Solution

DriveWorks Pro

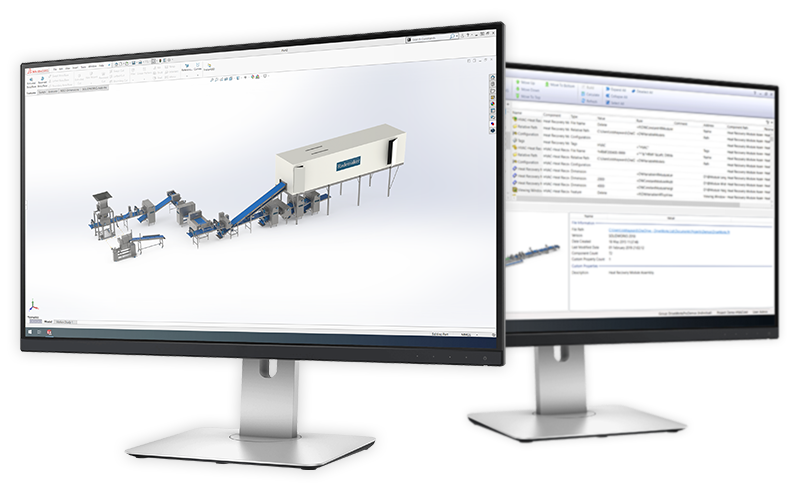

Rademaker were introduced to DriveWorks Pro by their SOLIDWORKS reseller, Visiativ. They evaluated the software and opted for the modules DriveWorks Administrator and DriveWorks Autopilot.

DriveWorks software is modular and easy to scale, allowing additional modules and functionality to be added at any time to suit business needs.

Custom product configurator and SOLIDWORKS automation

Using the DriveWorks Form Designer, Rademaker built custom input forms to specify their products. Rules set by the engineers guide product configuration and ensure only valid options can be selected.

The product specifications are used to automatically update the SOLIDWORKS parts, and assemblies and create production-ready engineering drawings. This removes repetitive tasks from the engineering team, freeing valuable resources for other tasks.

Modular implementation of DriveWorks has allowed Rademaker to reuse projects, driving standardization and improving engineering efficiency.

SAP PLM Integration

Rademaker also integrated DriveWorks with their existing SAP-PLM solution facilitating the process of standardization, change control, logistics, and sales.

DriveWorks integrates with other systems using ODBC connections, web services, static files, DriveWorks PowerPacks, and the DriveWorks API.

Results

Engineering time reduced to under 15 minutes

Rademaker achieved their target of reducing engineering time to less than 15 minutes for modular units. They also achieved a 30% reduction in time during the standardization process as DriveWorks enabled them to optimise their way of working with product structures.

Expanding product offering

Implementing DriveWorks has allowed Rademaker to increase flexibility, variants, functionality and the number of options they can handle.

Try DriveWorks Pro configurator examples online.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.