Industrial Magnetics

Industrial Magnetics accelerate product development, reduce the cost of custom designs and orders, enhance product quality and provide fast responses to customer requests using DriveWorks design automation and product configurator software.

Challenge

A significant piece of IMI’s business is creating custom products as per customer requests. With hundreds, and in some cases, thousands of legacy models, keeping pace with design changes to support these customizations while maintaining the desired pace for standard product releases proved challenging.

Solution

Already using SOLIDWORKS® 3D CAD software, IMI wanted to take an integrated approach to improve operations, with tools to accelerate product development, reduce the cost of custom designs and orders, enhance product quality and provide fast responses to customer requests.

Results

With DriveWorks at the core, the company has integrated its CRM and ERP system, creating a centralized platform to support day-to-day operations. IMI has cut the task of creating a Bill of Materials down to a single click from within SOLIDWORKS — a step that used to take up to four minutes and was conducted by all eight engineers multiple times per day.

Company overview

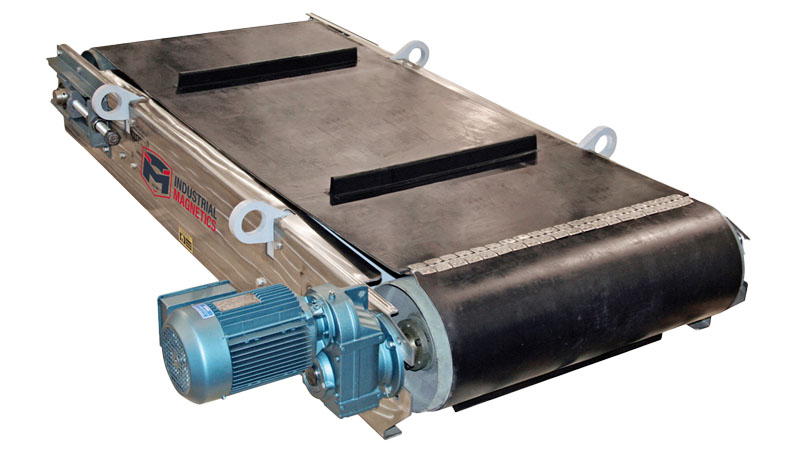

IMI is an industry leader in providing both permanent magnets and electromagnets for work holding, lifting, fixturing, conveying and magnetic separation.

The company specializes in providing personalized service, innovative solutions, and custom fabrication — designing, engineering and manufacturing industrial-grade magnetic products to meet customers’ specific requirements.

Challenge

Keeping pace with custom product enquiries

A significant piece of IMI’s business is creating custom products as per customer requests. With hundreds, and in some cases, thousands of legacy models, keeping pace with design changes to support these customizations while maintaining the desired pace for standard product releases proved challenging.

Already using SOLIDWORKS 3D CAD software, IMI wanted to take an integrated approach to improve operations, with tools to accelerate product development, reduce the cost of custom designs and orders, enhance product quality and provide fast responses to customer requests.

We pride ourselves on building just about anything to meet a customer’s needs and we’re looking for efficiency improvements to work smarter and faster.

David Dewey – Engineer

Industrial Magnetics

Solution

Reducing a four minute task to one click

With DriveWorks at the core, the company has integrated its CRM and ERP system, creating a centralized platform to support day-to-day operations.

“Everyone in the process stream — customers, sales, engineering, and manufacturing — can now see the same information,”. “DriveWorks serves as the interface to all our business systems, tools, models, terminology, and users.”

Customers can now see exactly what was configured and what they will receive, long before engineering has to sink the time in to generate a complete model with full production details.

David Dewey – Engineer

Industrial Magnetics

Results

Automating away the mundane

As a result of the integration of DriveWorks and SOLIDWORKS with the company’s ERP system, IMI cut the task of creating a Bill of Materials down to a single click from within SOLIDWORKS — a step that used to take up to four minutes and was conducted by all eight engineers multiple times per day. Now, the process is automated, adding in extra layers of error checking and streamlining the steps to eliminate manual intervention.

IMI recognizes that tapping into the creativity of staff plays a key role in maintaining success, supporting a trajectory of 10 percent year-over-year revenue growth. Removing repetitive tasks has allowed employees to focus more time on tasks that add value and cultivate a culture that values and supports talent.

Future

Adding more users

IMI’s long-term goal is to expand its use of DriveWorks and SOLIDWORKS, adding more users along the way — looking for opportunities to automate mundane or error-prone processes within engineering, marketing, sales, and management.

Try DriveWorks Pro configurator examples online.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.