Configuring a Custom Picture Frame

Personalised and custom products are becoming the norm. Customers are looking for products that meet their exact needs and are expecting better buying experiences.

Implementing an interactive online sales configurator enables your customers to configure their product, get instant quotes, accurate delivery dates, and even place their orders, in one simple session.

Online sales and digital manufacturing are key aspects of digital transformation.

Manufacturers using DriveWorks rules-based software can embrace digital transformation to improve customer experiences and make selling their custom products quicker, easier and more profitable.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action. Anyone can use the online configurators, created using DriveWorks software.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom picture frame online.

With DriveWorks 18, our team have added lots more 3D capability to bring the product to life. The picture frame is positioned in a 3D scene to give it context, you might recognise the scene from our Custom Furniture Configurator example.

I’m going to step through a series of options to specify my custom picture frame. I’ll choose a size – preset or custom – select frame and mount style, change colours, add optional extras and even upload a picture.

With every change I make and every option I select, DriveWorks software is working in the background to update the model on screen, change selections and show an up to date price throughout.

Once I’ve completed my selections, DriveWorks will create all the sales documents and manufacturing details automatically. That includes the SOLIDWORKS 3D parts, assemblies and drawings, cut lists, BOM and much more.

Realistic 3D

The picture frame in this online configurator example is shown in a realistic house interior 3D scene. The scene uses many of the 3D features in DriveWorks to add more visual interest to the configuration experience.

Screen-space reflections create a more realistic visual appearance, reflecting the walls, furniture and decorations on the floor and the cupboard.

Lighting effects such as Ambient Occlusion and Bloom are used to give realistic dark contrast and highlights.

An environment map has also been added to this scene, enabling glossy reflectiveness to appear on various surfaces.

Notice how the 3D textures change as selections are updated. Diffuse textures, specular textures and normal maps are crucial to creating a visually appealing scene.

The combination of all the 3D effects together adds high-quality realism to the configuration experience.

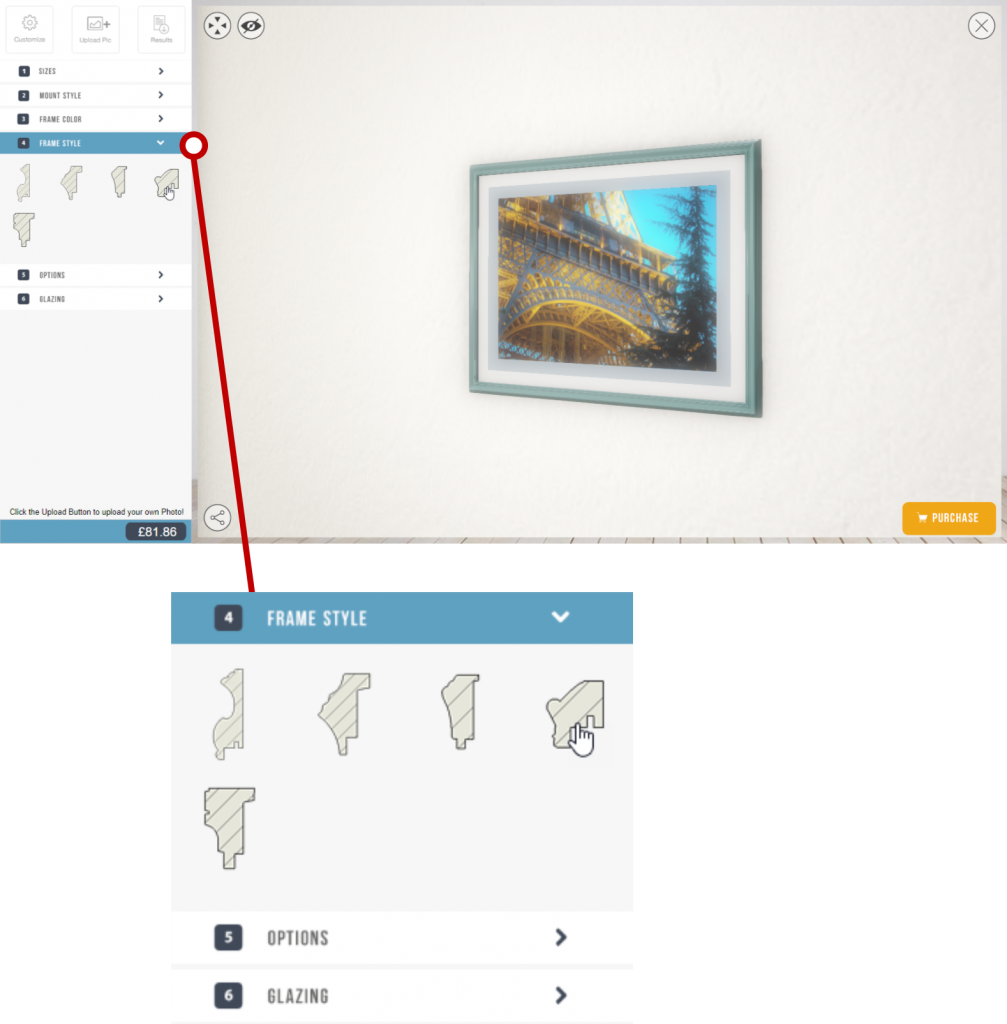

We can move around the 3D space to see the picture frame from all angles – this is great when choosing the profile for the frame style.

This configurator example also has the option to turn the 3D scene on and off so users can focus on the picture frame if preferred.

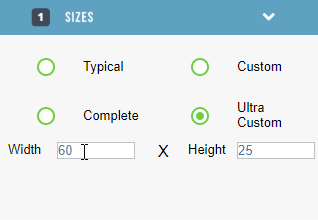

Changing Dimensions

The Form Designer in DriveWorks has several form control options. You design your own forms to suit your product, choose the form controls that make configuring your product easy.

In this example, we added standard sizes for users to select from a drop-down menu. We’ve also added the option to input completely custom dimensions so users can order the specific size they need.

You can set up your forms to suit your own products. You can set limits for dimensions, input your own set of standard sizes and control what users can configure.

As we make changes to the dimensions, the model changes immediately. DriveWorks works in the background to automate the changes made to the SOLIDWORKS model.

The price also updates to reflect changes in size.

The standard and custom sizes are driven by rules in the DriveWorks project.

When setting up a DriveWorks project, your engineers input their design rules and product knowledge. The rules and logic ensure users can only configure products that can be manufactured. This guided selling makes it easy for anyone to design a product that meets their specification, specific to your products and design constraints.

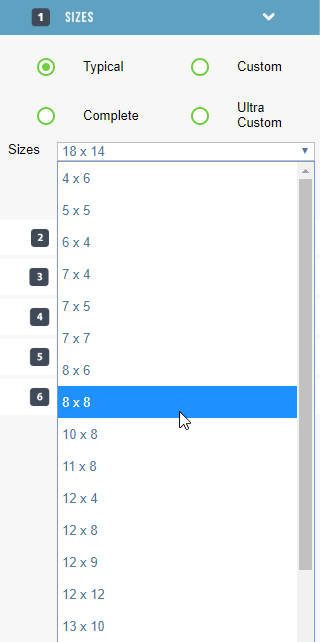

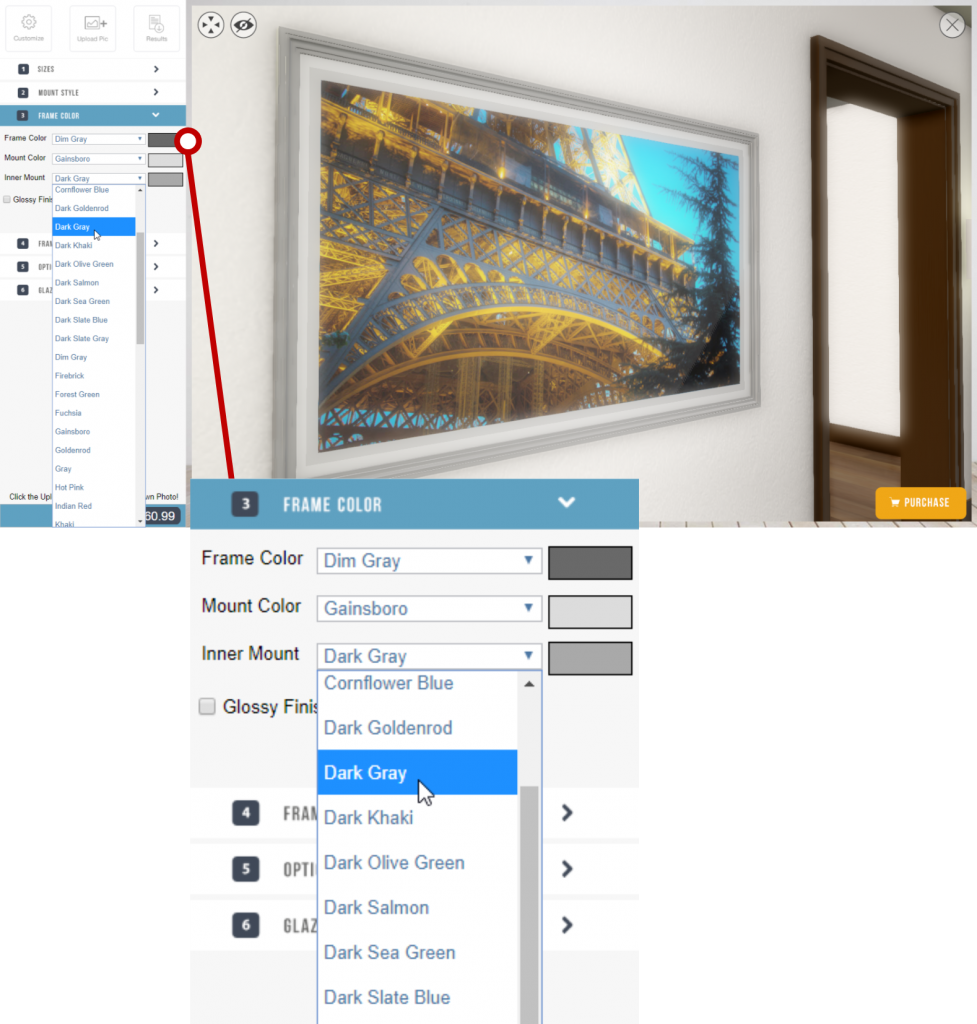

Choosing Colours

The colours in this picture frame example can be completely customised. We can change the colour of the frame, the mount and the inner mount. We can also choose a glossy finish.

Simple dropdown menus are used for colour selection. As we make a colour choice, the colour box on the form updates so we can see the selected colour. The model also updates so we can visualise the changes immediately.

Dropdown menus are just one of the ways you can display colour choices on your forms. DriveWorks has many different form control options so you can choose a format that suits you. For example, you could use colour wheels – like in our Cupboard Configurator example – or colour palettes – like in our Watch Configurator example.

Customising Frame Style

There are different frame and mount options to choose from.

We can explore the options and make changes in the configurator forms. As we make selections, the model updates to show how they look in the 3D model. The design and textures change whilst the price updates to reflect the options selected.

Choosing Glazing

There are four glazing options in this example – Acrylic, Glass, Mirror and None.

The 3D model changes as we select different glazing options. The glass appearance feature in DriveWorks is used and changes depending on the glazing option selected. The light reflects off the glass in different ways for each glazing option.

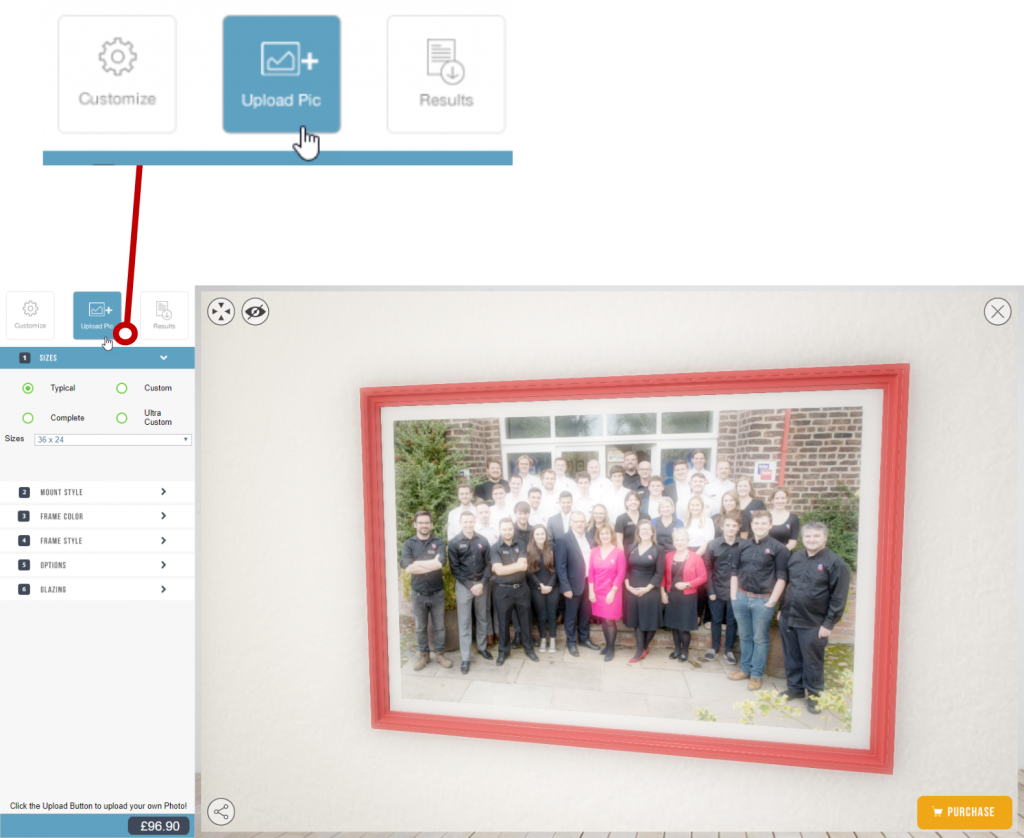

Picture Upload

Using DriveWorks technology, you can add a picture upload option to your forms. In this example, picture upload is used as a way of adding a photo to the picture frame – the ideal way to see exactly how the finished picture frame will look.

We click on the “Upload Pic” button located in the DriveWorks Form Controls and choose the photo to load into the picture frame.

This is just one example of how the picture upload option can be used. It’s useful in a variety of ways, in a variety of product configurators. For example, you could use this as a way of letting your customers add their logo to your product. See how you can upload graphics in our Kiosk Configurator example.

Order Review

Once we have finished configuring our picture frame, we can review our choices before submitting the order.

This is a great opportunity to review all of the selections made and at this point, it’s really easy to go back and make any changes to the custom design.

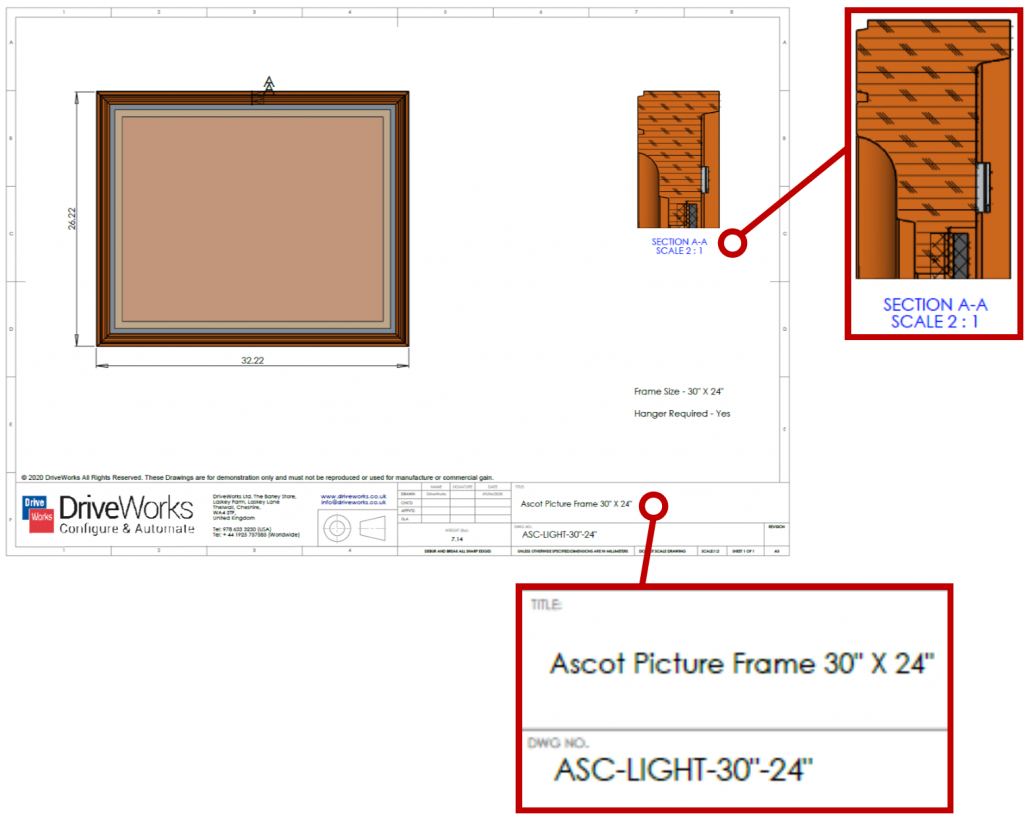

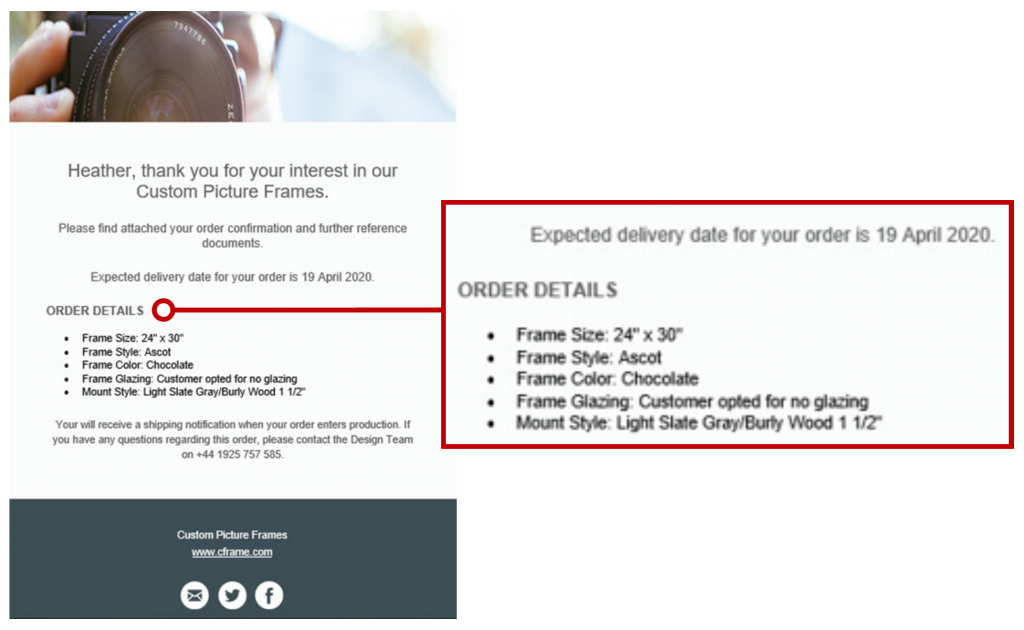

Automated Documents

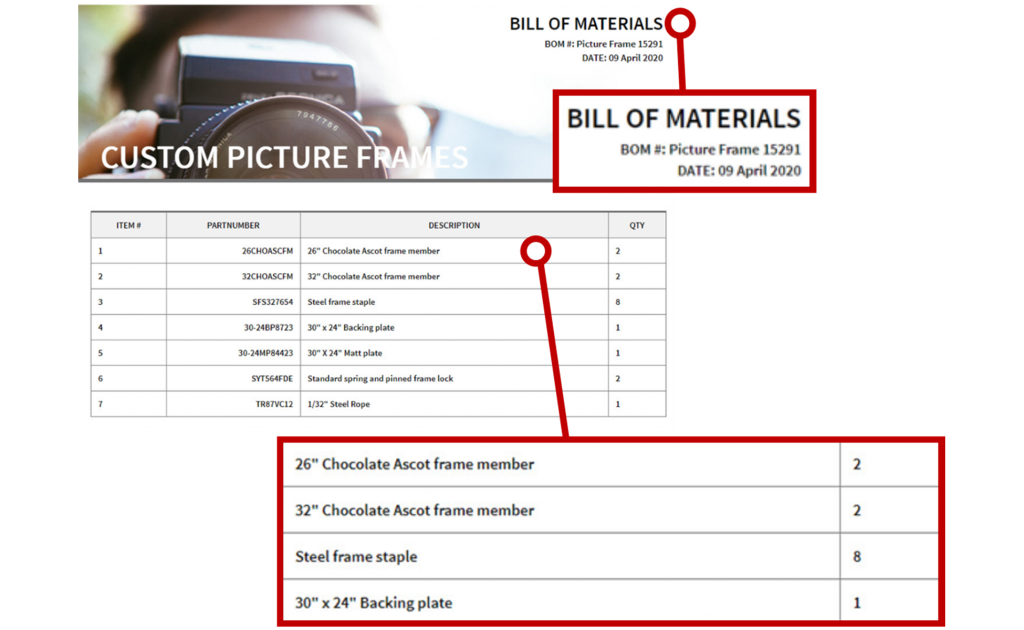

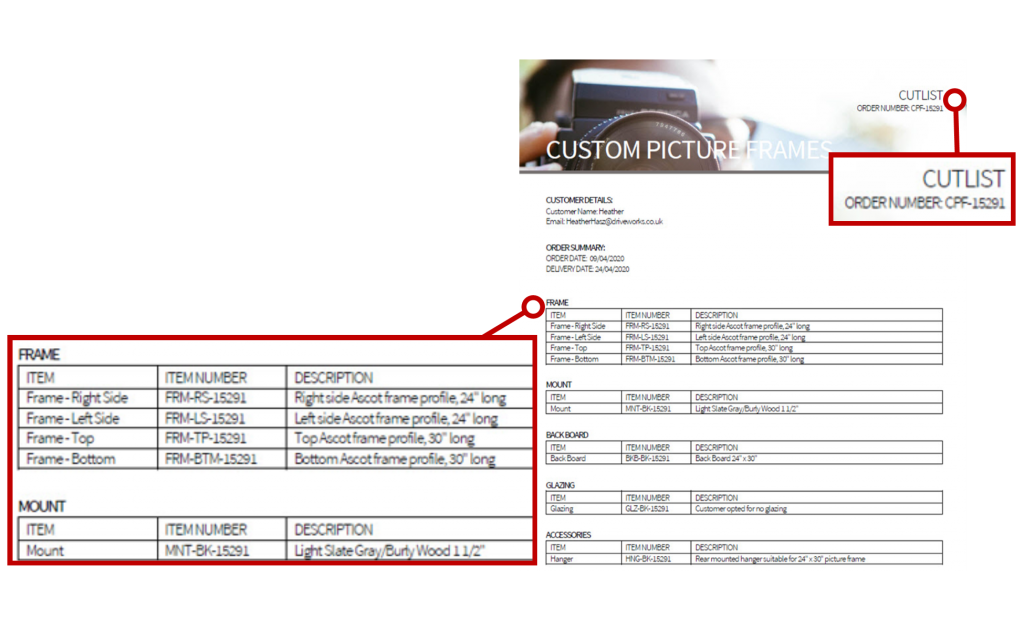

Once the order is submitted, the custom documents are automatically created. We receive a personalised cover letter, quote, bill of materials and a cut list.

Each document is unique and provides different information specific to this order.

In addition to receiving the cover letter and quote, DriveWorks also creates all of the manufacturing information.

A fully dimensioned drawing is generated automatically, saving valuable engineering time. The Drawing, Bill of Materials, Cut Lists and other files are sent to the manufacturing department so manufacturing can begin.

As the rules, logic and engineering knowledge have already been entered into DriveWorks, manufacturing can begin without engineers checking every detail and making changes to the design.

Rules mean customers, sales teams and distributors can only configure products that can be manufactured and the calculated outputs are correct.

The process is fully automated to reduce errors, improve quality and allow product designers and engineers to focus on innovating and improving.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This picture frame configurator is just one example of how DriveWorks can be used and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.