Configuring a Custom Cupboard

The furniture industry is one of many industries that can use the power of 3D for online sales and digital manufacturing.

Offering customisable products is a growing opportunity for many. Furniture designers and manufacturers using DriveWorks rules-based software can embrace digital transformation to improve customer experiences and make selling these custom products quicker, easier and more profitable.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action. Anyone can use the online configurators, created using DriveWorks software.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom cupboard online.

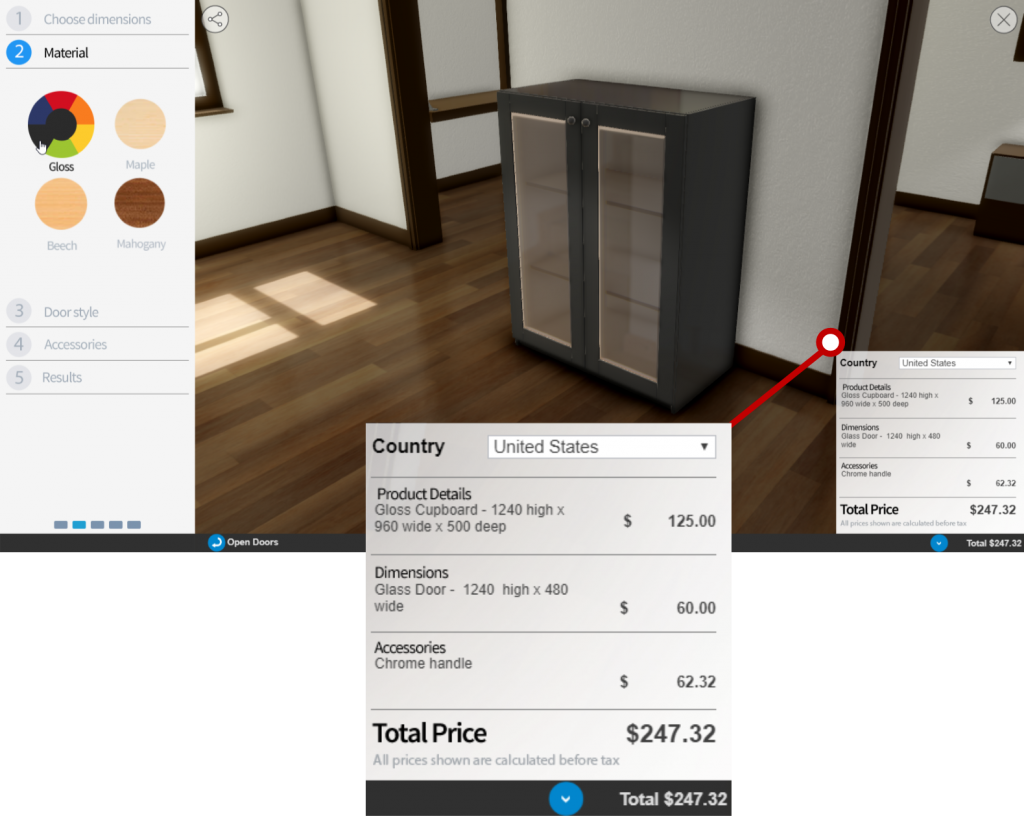

With DriveWorks 18, our team have added lots more 3D capability to bring the furniture to life. We’ve positioned the cupboard in a scene to give it context and a more realistic feel.

I’m going to step through a series of options to specify the size of my cupboard. I’ll enter measurements for the height, width and depth, and then select the material that I want my cupboard to be made from.

With every change I make and every option I select, DriveWorks software is working in the background to update the model on screen, update selections and show an up to date price throughout. Once I’ve completed my selections, DriveWorks will create all the manufacturing details automatically. That includes the SOLIDWORKS 3D parts, assemblies and drawings, cut lists, BOM and much more.

Realistic 3D

The cupboard in this configurator example is shown in a realistic house interior 3D scene. The scene uses many of the 3D features in DriveWorks to add more visual interest to the configuration experience.

Screen-space reflections create a more realistic visual appearance, reflecting the walls, furniture and decorations on the floor and the cupboard.

Lighting effects such as Ambient Occlusion and Bloom are used to give realistic dark contrast and highlights.

An environment map has also been added to this scene, enabling glossy reflectiveness to appear on various surfaces, especially the wooden finish cupboard.

The glass appearance feature in Driveworks is used on the glass panels on the cupboard doors, giving them a shiny appearance, so they stand out and look more visually appealing.

Diffuse textures, specular textures and normal maps are crucial to creating a visually appealing scene.

The combination of all the 3D effects together adds high-quality realism to the configuration experience.

Changing Dimensions

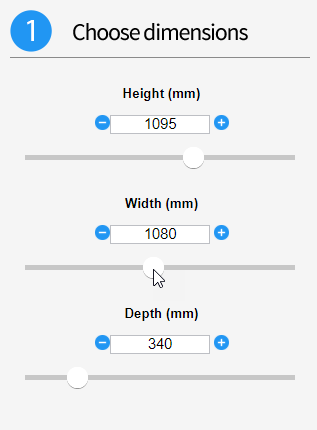

The DriveWorks Form Designer has many different Form Control options you can use to make it easy for anyone to configure your products.

For changing dimensions, this example uses slider controls with a text input, as well as options for incrementally increasing and decreasing the values.

There are minimums and maximums set for each value, controlled by rules in the background.

As the height, width and depth changes, the model updates and you can immediately see the new configuration in the room.

DriveWorks technology has fully automated the SOLIDWORKS model and makes the changes upon input.

With every change made, the price and the details in the bottom right corner are updated to reflect the latest selections.

Choosing Materials

There are many DriveWorks Form Control options for displaying material and colour options.

This cupboard configurator has 4 material options – maple, beech, mahogany and gloss. When choosing gloss, a colour wheel appears to allow the user to choose from 6 colour options.

As a material is selected, the cupboard is updated, and the pricing reflected.

Selecting Door Style

There are 3 door styles available to choose from – flat, glass or shaker.

When choosing any of these options, the model is updated again and the price is adjusted.

This is just the start of what could be added to a cupboard configurator, you could also add options for number of doors, number of panes of glass, number of shelves, adding a lock – the possibilities are endless.

DriveWorks is flexible and scalable so you can start with the basics and add to it.

Interactive 3D

To improve interactivity and responsiveness, this cupboard example includes animation.

The doors open and close when clicked, or when using the Open/Close Doors button at the bottom of the form.

Whilst this doesn’t make any changes to the configured product, it gives the user a more interesting configuration experience, and is a good way to allow a clearer view of the product interior.

As you make changes to the cupboard, the transitions are smooth thanks to more animation. This smooth transition makes it much easier to see the difference each selection makes, for example when changing dimensions, the cupboard size updates as you move the slider.

3D is a key feature in DriveWorks and there are many other ways to make models interactive.

For example, in this cupboard configurator, you could add the ability to move and position shelves and handles based on where the user clicks on the model.

Adding Accessories

There are three handle options in this example and with intelligent rules and logic inside DriveWorks, if the colour of the model changes, the colour of the handle changes too.

Order Review

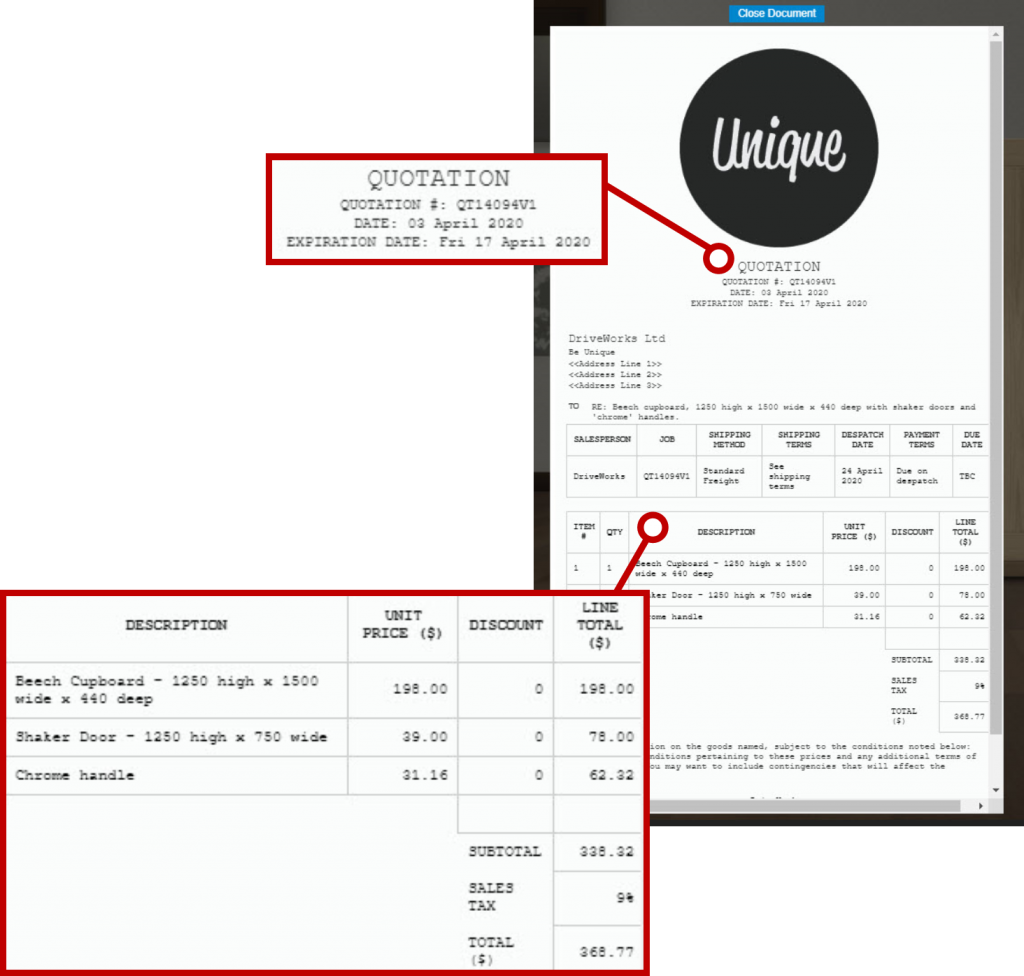

After following through each step on the easy to use forms, I now have a completed cupboard design.

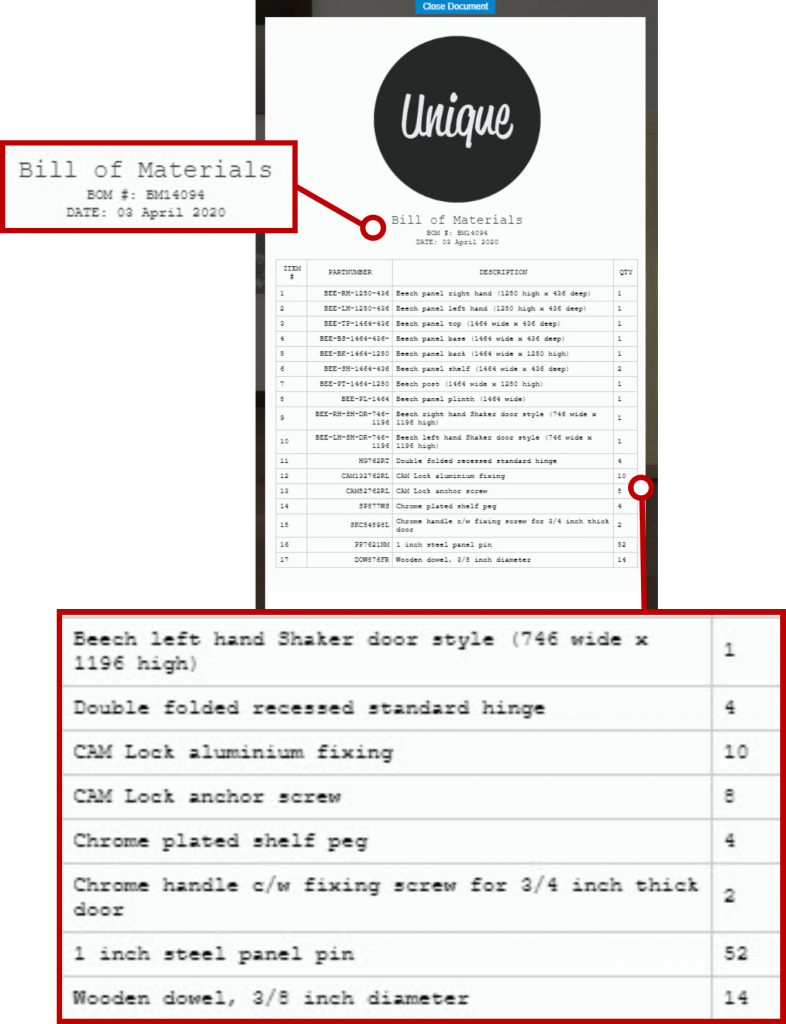

In the review section, there are documents showing details of this custom order. There’s a cover letter, quotation, bill of materials and the cut list.

This is a great opportunity to review all of the selections made and at this point, it’s really easy to go back and make any changes to the custom design.

You can see how each document is unique to this specific order. DriveWorks has even calculated the number of dowells, screws and pins needed and assigned a number to each document.

There are sales documents and manufacturing documents displayed here. If your configurator is customer facing, you might not decide to show these details at this stage.

However if your sales teams or dealers and distributors are using your configurator to sell your products, the manufacturing documents are useful at this point.

Remember, this is just an example and you can set up your configurator to suit your products and business needs.

Automated & Custom Outputs

Once finished, we hit the ‘Complete’ button on the form and the order is submitted.

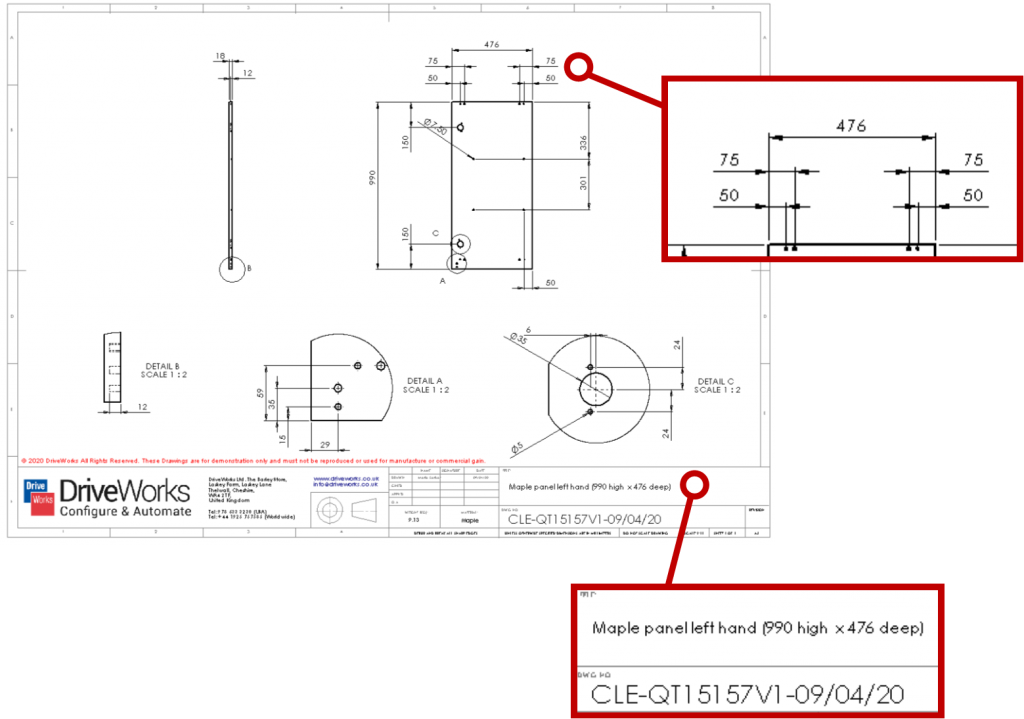

DriveWorks immediately generates the order-specific sales and manufacturing documents.

A cover letter and quote are both sent via email to the customer and the sales team.

A fully dimensioned drawing is generated automatically, saving valuable engineering time. The Drawing, Bill of Materials, Cut Lists and other files are sent to the manufacturing department so manufacturing can begin.

As the rules, logic and engineering knowledge have already been entered into DriveWorks, manufacturing can begin without engineers checking every detail and making changes to the design.

Rules mean customers, sales teams and distributors can only configure products that can be manufactured and the calculated outputs are correct.

The process is fully automated to reduce errors, improve quality and allow product designers and engineers to focus on innovating and improving.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This cupboard configurator is just one example of how DriveWorks can be used and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.