Companies in the HVAC industry are using DriveWorks design automation & sales configurator software to improve manufacturing processes and sell more.

The HVAC (Heating, Ventilation and Air Conditioning) industry includes manufacturers of air conditioners, industrial electric fan heaters, large heaters, commercial dehumidifiers, coolers, fans and more. HVAC is essential to all modern building designs and has seen a surge in demand following the pandemic. With more demand for products, and increased urgency, HVAC manufacturers are turning to digital technologies to do more with less.

Read on to learn how HVAC manufacturers are improving processes and selling more with DriveWorks.

Carrosserie Cazaux

Based in France, Carrosserie Cazaux was founded in 1983. Carrosserie Cazaux is a leading manufacturer of custom-made refrigeration units for carrier vehicles of up to 26 tonnes, as well as containers, cold rooms, trailers and custom units.

Carrosserrie started using DriveWorks Solo in 2019 and used it to develop a configurator inside SOLIDWORKS that drives dimensions and appearances.

They have also automated the placement of different features on a model.

When describing how DriveWorks has benefitted the company, Guillaume Guerin, design engineer at Carrosserie Cazaux says that “DriveWorks is interactive and fun to use, more flexible, and benefits from the excel syntax in the rules builder.”

At Carrosserie, DriveWorks is used internally by the engineering team.

Since implementing the software, they have found it much easier to train up new members of the team, owing to the simplicity in writing the rules and in using the software itself.

Carrosserie Cazaux also uses DriveWorks Solo to automate the creation of manufacturing data and drawings.

The image on the right shows an example of a custom 2D drawing that has been automatically generated by DriveWorks Solo inside SOLIDWORKS. Each drawing is updated and customized with the company logo, the designer, the date and the client. It is then ready to be sent to the manufacturing floor.

Carroserrie Cazaux have also benefitted from the ability to design their own forms inside DriveWorks Solo. These then appear in the SOLIDWORKS task pane.

Learn more about how Carrosserie Cazaux are saving time by driving new variations with DriveWorks Solo:

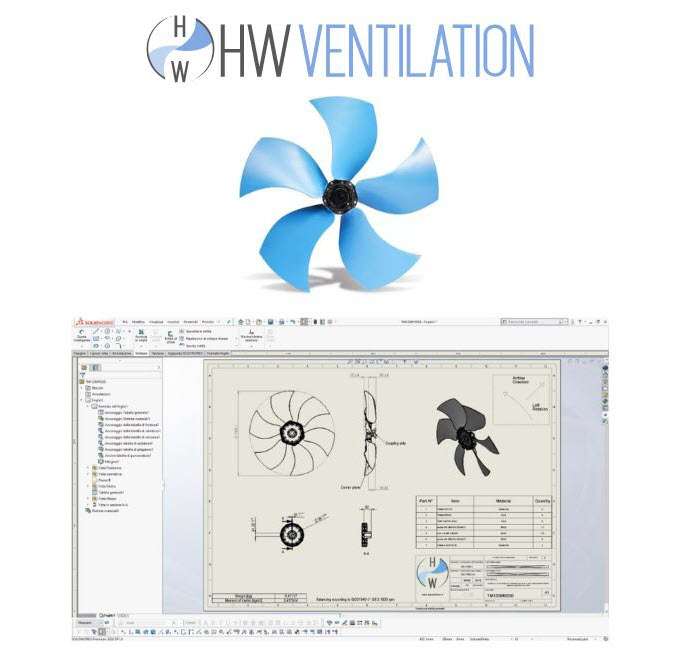

HW Ventilation

HW Ventilation, based in Rescaldina Italy, is a leading manufacturer of ventilation and air movement systems. They design, produce and sell axial impellers and ventilators for industrial use. This includes engine cooling systems, compressors, industrial plants and HVAC systems.

HW Ventilation’s lengthy design process required an engineer to draw every new product or variation of an existing product from scratch inside SOLIDWORKS.

Now, with DriveWorks, they spend a lot less time drawing the same but different designs.

Automating repetitive modelling tasks has enabled HW Ventilation to quickly generate 3D models of any type of fan, based on a set of standard variables, such as blade and hub types, fan diameter, material and colour rotation.

The DriveWorks Solo project also automatically generates brand new SOLIDWORKS files and manufacturing data, such as bills of materials and 2D drawings, based on each individual form input.

They achieved their target of reducing engineering time spent on repetitive and low value-add activities.

As a result, they are able to respond to customer demand faster and with more efficiency. HW Ventilation are making plans for what’s next with DriveWorks. Matteo Morlacchi says that their next step will be to scale up their current DriveWorks Solo projects to DriveWorks Pro and implement an online configurator that will enable their customers to configure products online.

Learn more about how HW Ventilation’s design process is 10 times faster with DriveWorks Solo:

Monmouth Scientific

Monmouth Scientific are UK market leader in clean-air solutions. They specialise in filtration and ducted fume cabinet installations. Monmouth Scientific offer a standard range of products and also design and manufacture bespoke systems.

Monmouth Scientific’s end goal with DriveWorks was to have a clean room configurator that would enable the customer, assisted by the sales team, to design their own bespoke cleanroom. This was developed using DriveWorks. One of the key features of the configurator is the 3D preview functionality as it allows the user to see an interactive 3D model of the item they are configuring.

Users can also dynamically interact with 3D in the configurator to create interactive 3D layouts. For example, a user can click around the form to build their bespoke clean room, with the model automatically updating in 3D on the form. They can rotate the model, add walls to the cleanroom and see what their end product will look like.

Introducing the 3D configurator has saved both the sales team and the design team a lot of time in the design-to-order process.

Previously the sales team would manually do some rough sketches of the customer’s layout, or they would ask the design team to create a 3D layout in SOLIDWORKS, which was understandably time-consuming.

Now they can have a 3D image for every quote and they can interactively work through the layout with the client. The design information that comes through to the design department is much more accurate.

Learn more about how Monmouth Scientific use 3D to enhance user experience with DriveWorks Pro.

Explore our DriveWorks Configurator examples, and see different examples of how DriveWorks can be used for design automation and digital selling. Our HVAC configurator example shows what’s possible with DriveWorks. Explore and interact with this and other examples at DriveWorksLive.com

Try DriveWorks Solo for free

Get instant access to DriveWorks Solo for 30 days. No credit card required.