Markets are changing, and customers are expecting more from the products and services they are buying. Consumers want products faster, cheaper and easier than ever before, without compromising on quality. This is presenting a challenge for many buisnesses. To meet demand, manufacturers are looking to automation.

Design Automation

Design automation is enabling businesses to turn around proposals quickly, design and manufacture efficiently and deliver on promises consistently, all whilst maintaining a healthy profit.

By automating time-sensitive and often repetitive activities, businesses can focus on innovation and adding value to their products, improving throughput and quality to meet customers’ requirements.

Becoming smarter, agile and much more flexible means manufacturers are able to achieve increased productivity and stay competitive.

Mass Customisation

According to Digitalist Magazine, “manufacturing is transforming from mass production to an industry characterized by mass customisation”.

Customer expectations are growing, and the demand for personalisation and customization is rising. Unlike the second industrial revolution, customers don’t want mass produced identical goods. They want value-adding customised products.

Gartner emphasizes that the goal of digitalisation is to create and deliver new value to customers, not just to improve what is already being done or offered. To adapt to this, enterprises and manufacturers are changing strategies, embracing new technologies and ‘going digital’.

By offering customers exactly what they want, businesses are increasing demand for their products and increasing revenue.

Automation in Manufacturing

The Annual Manufacturing Report 2019 suggests that digital technologies are driving modern manufacturing machinery, allowing for mass customisation. Modern customisation is bringing change, allowing even small companies to serve a wide variety of customer demands on the production line.

Offering customized products and services is a great competitive differentiator, leading to more sales, higher revenues, and happy customers.

However, manufacturers offering custom products are often putting their engineers under pressure. They’re squeezed to create proposal documents and drawings as fast as possible. This leads to best guess costings, for orders that aren’t guaranteed.

Engineering departments are wasted on tasks that could be automated. They have less time to update drawings and carefully check every detail. Jobs are then left open to errors, rework, backlogs and delays. All of this can affect profit margins and damage reputation.

Benefits of Automation

With DriveWorks, many manufacturers are already seeing the benefits of design automation.

Automation is freeing up engineers, giving them more time to focus on improving product quality and developing new products.

Sales teams are becoming more proficient meaning customer inquiries are being dealt with faster and throughput is increasing.

Automation is leading to more orders, reduced operational overheads, and better customer service one step at a time.

Activate to Automate

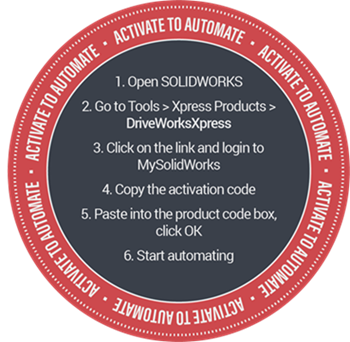

Ideal for configuring designs that are the Same but Different, DriveWorksXpress provides entry-level Design Automation inside world-leading, 3D CAD design software, SOLIDWORKS.

Use it to create multiple variations of SOLIDWORKS Parts, Assemblies and Drawings quickly and accurately.

Save time, reduce repetitive tasks and minimise costly errors.

DriveWorksXpress is the time-saving Design Automation tool included free inside every licence of SOLIDWORKS, all you need to do is activate it.

This is the fourth blog in our new digital transformation series. Each week we will be sharing our insights about the importance of embracing digital transformation and automation. Keep reading to learn more!