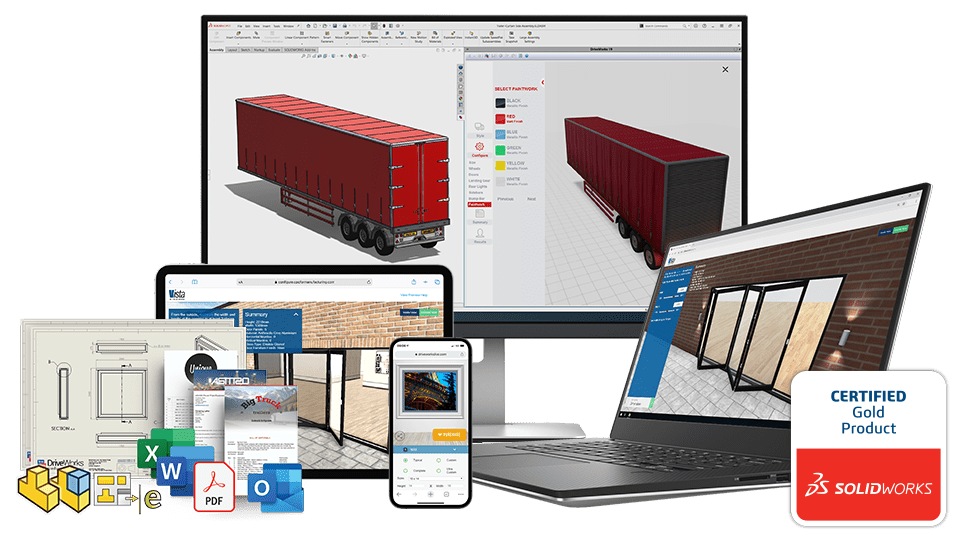

DriveWorks is used by manufacturing companies from a range of industries. DriveWorks is modular, scalable and incredibly versatile so our customers use DriveWorks in many different ways, customising their Design Automation and CPQ solutions to suit their needs.

We’re always interested to hear the different ways our customers use the software we’re proud of, we regularly post customer case studies on our blog. Here are a selection of quotes from some of those case studies…

“What I knew of DriveWorks was that it was a CAD automation system. But, once we started exploring the product, it became very obvious that it could do much more —reaching into our existing business systems to reuse data that could change how we connect with end-users and distributors to drive more sales.”

-Pete Robinson, Manager of Engineering Systems with WernerCo

Introducing DriveWorks has revolutionised the way IMA design their products. They have now configured DriveWorks for layout and component designing.

“DriveWorks has played a crucial role in our day to day work, helping us to achieve two important goals; time-saving and accuracy.”

– Mr Mayur Patil, Manager, IMA PG

“We really believe that it has made it very easy to specify a system, so our biggest benefit from implementing design automation into our company is the user experience, giving the customer the ability to configure our product and be able to see all the different configurations available from that product in real-time. ”

– Jonathan Beattie, Managing Director, Dolphin Solutions

HSI has been using DriveWorks since 2017, to automate the design process of their cranes. They started initially using DriveWorks Solo.

“End users are so happy that they don’t have to sit around waiting for a quote, that they keep returning faster and they can do it on the site too”

– Michael Townsend, Lead Mechanical Designer, Handling Systems International Inc

“Thanks to DriveWorks, we provide quotes and drawings for each custom order, at no extra cost. Customers can get a quote anytime they want it, 24/7/365. With every order, customers receive everything they need. We are building customer loyalty, increasing sales and avoiding mistakes.”

– Richard Twiddy, Design Office Manager, F.H.Brundle

“For us, the most important thing about DriveWorks is the ability to create custom bespoke software utilising visual wizards rather than heavy coding. This allows our company to build and customize quickly and easily. We now have more time to focus on our workflow and business analytics ”

– Adam Baker, Operations and IT Manager, BKW Instruments

“DriveWorks has allowed us to automate the routine processes that we undertake day in and day out, with traditional bridge design. This automatic creation of models and drawings rapidly improves the turnaround time to reach sign-off on designs and makes all downstream benefits possible”

– Dr Scott McGovern, Digital Engineering Lead, Laing O’Rourke

“DriveWorks has allowed us to automate the routine processes that we undertake day in and day out, with traditional bridge design. This automatic creation of models and drawings rapidly improves the turnaround time to reach sign-off on designs and makes all downstream benefits possible”

– Dr Scott McGovern, Digital Engineering Lead, Laing O’Rourke

“We use DriveWorks for quoting and approval drawings for almost 160 teams and 530 users. We also use DriveWorks for production part component generation for various product lines and a whole bunch of other great stuff!”

– Christopher Zona, Manager – Systems Automation, Blue Giant

“We value many things about DriveWorks.

Most importantly is the ability to take a design standard and use the configurator software to produce an error free streamlined custom

bearing design.”

– Ray McDaniel, CAD Engineer, Oiles America Corporation

“For us, the most important thing about DriveWorks is definitely the time saving benefits. We can accommodate much tighter delivery schedules and still have the room to innovate and adapt to meet our customers’ requirements.”

– Chris Kinder,

Design Department,

Pattern Forme Ltd

“With DriveWorks Pro, we have been able to design our products with greater accuracy, consistency and productivity. We’re pleased with our experience so far and we’re excited about where we can take this experience in the future.”

– Design Team,

ZCL Composites

Inc.

“Before using DriveWorks

we would create 20 quotes in a month, now we can do 20 in a day.

The process in the past was labour intensive as prices need to be calculated each time and

drawings all had to be prepared manually.”

– David Martin, Managing Director, Elite Balustrades

“We truly hope and believe DriveWorks will generate

an extremely short

pay-back in getting

Clear Vision Cooling off the ground”

– Jurnjan van den Bremer, Commercial Direction, Clear Vision Cooling

“There was the need for a time saving process to reduce engineering time, so called Zero Effort Engineering (ZEE). When implementing DriveWorks Pro, our target for order-engineering was to go back from 2 hours to 15 minutes. This target has been achieved with DriveWorks.”

– Rob Beffers, Manager Integrated Process Control, Rademaker BV

“We implemented DriveWorks Pro and saw a 55-minute process go down to 30 minutes. The benefits of Design Automation are very, very real.”

– Dave Mandl, New Product Development Engineer,

Séura

“At NGI, my main challenge is to create documents

for a lot of parts, and this has proven pretty

difficult to do

without DriveWorks.”

– Tomas Hecht Olsen,

R&D Manager,

NGI A/S

“One consistent software package that simplifies quoting and ordering and is easy to use, for our in-house customer service and our external distributors.”

– Terry McGowan, President and CEO at Thordon Bearings

Software

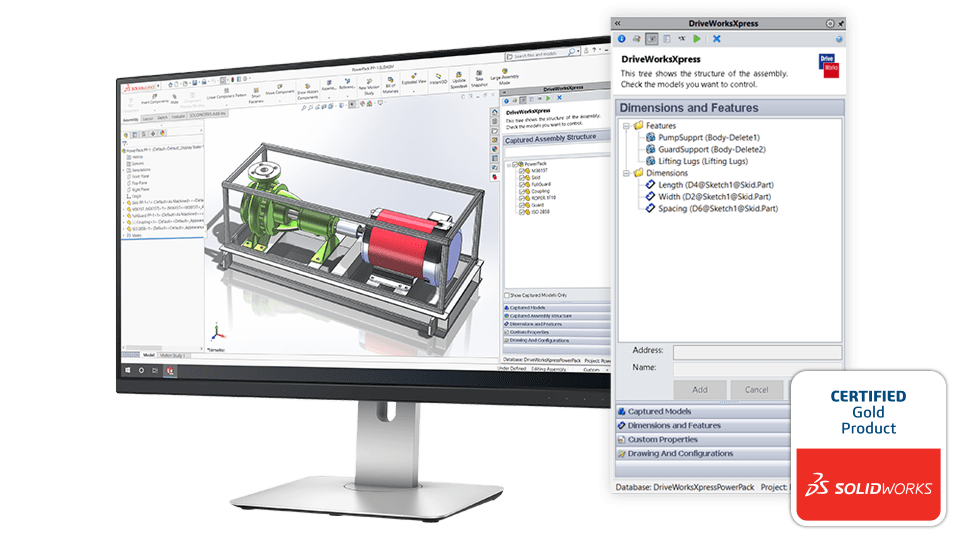

SOLIDWORKS® design automation and product configurator software

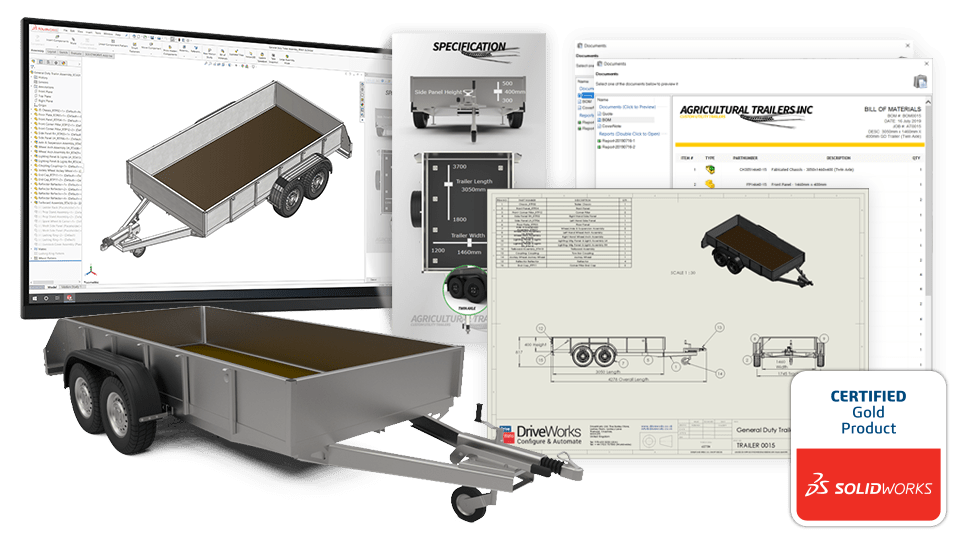

DriveWorksXpress

DriveWorksXpress entry-level design automation is included free in every seat of SOLIDWORKS®. Upscale to DriveWorks Solo or DriveWorks Pro anytime.

DriveWorks Solo

Powerful SOLIDWORKS® design automation. Download your 30-day free trial of DriveWorks Solo.

DriveWorks Pro

Complete SOLIDWORKS® automation and online 3D CPQ configurator software. Try one of our configurator examples now.