Setting Sail for Efficiency

In ship design, every component plays a crucial role in ensuring safety, efficiency, and functionality. KARACA GEMI, a leading Turkish company specializing in the design and development of specialized glass for ships worldwide, understands the importance of precision and agility in their design process.

With the implementation of DriveWorks Solo, KARACA GEMI has transformed its approach to customer requests, leading to improvements in efficiency, accuracy, and customer satisfaction.

Challenges in Traditional Design Processes

Before integrating DriveWorks Solo into their workflow, KARACA GEMI faced several challenges in their design process. They relied on time-consuming methods such as recreating parts in 2D CAD or using SOLIDWORKS Pack and Go, resulting in lengthy processes and incomplete models missing essential information. This not only added time to the sales and design process but also led to manufacturing errors and inefficiencies.

The DriveWorks Solo Advantage: Revolutionizing Design Automation

Since implementing DriveWorks Solo, KARACA GEMI has achieved several goals:

- Reducing the time taken to create 3D drawings of specified parts

- Automatically generating accurate and relevant documents

- Reducing the number of errors during the manufacturing process

Reducing Design Time and Errors

The implementation of DriveWorks Solo delivered several benefits for KARACA GEMI. With DriveWorks best-in-class SOLIDWORKS automation, they have streamlined their design process, significantly reducing the time required to create 3D drawings of specified parts. They now automatically generate accurate and comprehensive documents, eliminating errors and ensuring that each design meets the exact requirements of the customer

Empowering Every KARACA GEMI Team Member: Easy-to-Use Guided Selling

One of the key advantages of DriveWorks Solo is its ease of use and accessibility. It enables every member of the KARACA GEMI team to configure customer specifications, even if they haven’t used the program before. This guided selling approach not only improves workflow but also provides customers with a seamless and personalized experience.

Automated Document Generation: Ensuring Accuracy and Efficiency

DriveWorks document generation capabilities ensure that all files are automatically generated, named, and ordered correctly, saving time and reducing the risk of errors. Whether it’s a 3D model of the requested product or a detailed Bill of Materials, KARACA GEMI can efficiently deliver the necessary documents to their customers in various file formats.

“Thanks to DriveWorks, unnecessary time wasting is behind us, and we can use this gained time to do more Research & Development.”

Erhan Kusculu, Co-Founder and CFO at KARACA GEMI

Looking Ahead:

Exploring DriveWorks Pro

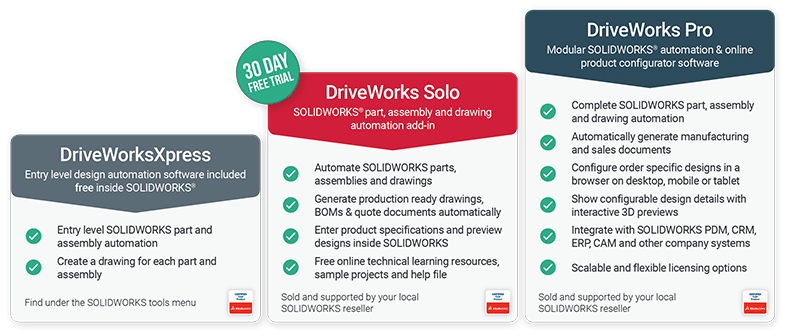

KARACA GEMI plans to explore the scalability of DriveWorks by upgrading to DriveWorks Pro.

With the implementation of an online configurator, they aim to further develop their custom order capabilities.

Get to Know DriveWorks Solo

Use DriveWorks Solo to configure and automate custom products inside SOLIDWORKS®.

Quickly and easily create and configure custom products with a free 30 day trial of DriveWorks Solo, part, assembly, and drawing automation inside SOLIDWORKS®.

Join Us at DriveWorks World 2024 to Hear More Customer Stories

Have you registered for DriveWorks World 2024? DriveWorks World is a value-added virtual event, hosted by DriveWorks experts. It’s a celebration of innovation, knowledge sharing, and technical expertise free for DriveWorks Customers with Active Subscription, Resellers, and Partners to attend. Customer stories are a valuable part of the event and provide an opportunity for you to learn how other business are overcoming challenges with DriveWorks technology.