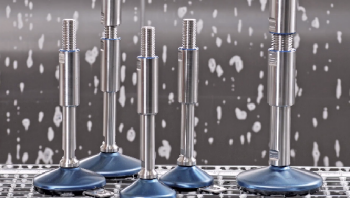

NGI A/S is the world leading manufacturer of a wide range of machine feet in stainless steel and reinforced polyamide for adjustment, stabilization and vibration absorption of all types of machines and equipment.

The Challenge

“At NGI, my main challenge is to create documents for a lot of parts, and this has proven pretty difficult to do without DriveWorks.” – Tomas Hecht Olsen, R&D Manager.

“Four years ago we only had what we were selling, and if we sold something new or had a customer asking for something new, they would need a drawing and it would take nearly one day. Today, they can just grab it on the internet, look at it, see the measurements and if they like it, they can have the drawing.”

The Solution

“Today we have drawn 15,000 extra products on our website and these drawings are not drawn by engineers, they are drawn by logic and spreadsheets.”

“Design Automation has an effect on all of the departments at NGI. For example, in marketing we have a very fast upload of drawings, pictures and especially pictures where you have to do a render. It takes time, but we can do that at weekends and we can do hundreds of products at the same time.”

“On Monday morning, we just upload it to the internet site and we would have photo realistic pictures on all of our products.”

“When we look at production, automisation has helped us with getting the same DNA in our drawings. Our drawings have the same look, whether it’s a small part, big part, special part for one thing or another. They’re drawn the same because they’re drawn from the same rules and regulations.”

Results With DriveWorks

“The engineering department gained a lot of time that we can use on developing new products and innovating new systems. To get that time, we need to get the automation system to do the drawing or the boring work and we do all the fun work, and that’s much better for NGI.”

“My vision for this system is that the customer can get exactly what they want by going to our home page, choosing their product and ordering. Without any engineers involved, the order would go through our ERP system, down to the production, put in the package area and we would just pack it, put a stamp on it and it would be finished. That would be beautiful!”

“Today we have 15,000 actual products on our website, and those products are not drawn by engineers, they are automatically created by logic and spreadsheets”

Tomas Hecht Olsen, R&D Manager