DriveWorks delivers full documentation in minutes rather than days

LBH International A/S has implemented DriveWorks to automate the generation of all technical and sales documentation, delivering significant time and cost savings as well as improved quality in its production of steel compensators.

PLM Group, a DriveWorks reseller in Scandinavia, recently published this informative DriveWorks case study revealing the results that LBH International A/S have achieved using DriveWorks and we wanted to share it with you.

Danish company LBH International A/S has automated the generation of both its technical and sales related documentation by using DriveWorks.

All technical drawings, static calculations, production papers and offers for new round steel compensators are now created automatically with just a few entries in the customized DriveWorks interface, which is programmed by the company itself.

Previously it could take up to one day to generate the necessary documents, however following the introduction of DriveWorks, the full documentation for a specific case can be generated in only a few minutes.

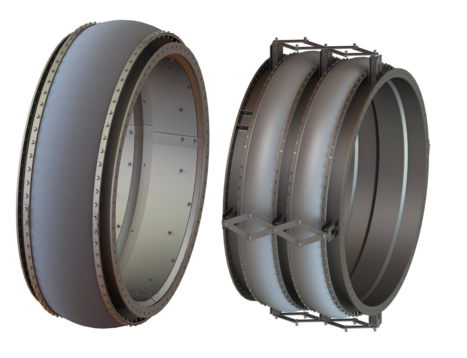

LBH International A/S manufacture compensators for industrial use in several materials including steel, rubber and tissue.

They are now using DriveWorks to configure round steel compensators, where the system handles more than 20,000 variants. The next step for LBH International is to enter their other product types into the system to effectively manage all of their product types.

“When you have been sitting for a long time drawing the same thing over and over again in a CAD system, you begin to wonder is it could be done easier. PLM Group explained to me that it could be done easily by adding DriveWorks to SOLIDWORKS“ says technical director Erik Pedersen, LBH Internaltional A.S.

Professional documentation with DriveWorks

“When we press the button, it takes only a few minutes until all documents are ready for use in production and sales, and everything is in an extremely professional quality. During one morning I have been able to to very easily generate about 150 main drawings with the accompanying detailed drawings. Previously, it could take up to a day’s work to generate the same documents for only one product.” Says Erik Pedersen.

LBH International A/S’s calculation standards for round steel compensators has been added to DriveWorks. Using these standards the static calculations for all variants are performed, and the selected materials, geometries and shapes are shown statically via the user interface. When statics and design fits the given application, the product configurator exports the data to SOLIDWORKS, which generates the desired 3D models from a master model where all the geometrical dependencies are defined. After receiving the data, SOLIDWORKS generates the main drawings, detailed drawings, static strength calculations, and control documents, and not least, the offer documents to customers with both technical information and prices.

Fewer errors and higher quality

DriveWorks has not only offered vast time savings but the quality of both technical documentation and the production base has been greatly improved. The company previously used 2D, and in recent years 3D CAD, to design the round steel compensators, while the static calculations were done in an Excel spreadsheet.

Now the possibility for errors due to double data entries in different systems has been eliminated, explains Erik Pedersen:

“Our rate of errors has been greatly reduced because far fewer human hands and computer keystrokes are mixed up in the process and we almost never make mistakes, for example, when we are cutting parts with laser based cutters.”

DriveWorks provides a significant economic benefit

According to Erik Pedersen the introduction of DriveWorks has also resulted in significant economic gains in terms of savings:

“To produce just a fraction of the drawings we generate now, without DriveWorks we would have been forced to hire more technical designers to do the drawing work. In addition, the time to process the casework has been significantly reduced. When our sales people are calling with customers, they can promise to send them the offer drawings and prices within 15 minutes.”

“A further benefit to customers is that we always send uniform drawings, so when we meeting with them, we seem more credible.When dealers or customers are questioning if we, as a relatively small company, can handle the large volume of inquiries, it’s now easy for us to guarantee that we can handle even very large amounts of both inquiries and actual orders.”

The use of DriveWorks at LBH International A/S will be continuously developed and expanded, explains Erik.

“DriveWorks has become the focal point for us. It is the system that both sales people and technicians need to log in to make offers and drawings and whatever else they need.”