IMA PG is a leading pioneer in packaging solutions in India. Operating in the pharmaceutical industry, they’ve been designing and manufacturing machinery for various pharmaceutical products and tablets since 1961. IMA PG work closely with DriveWorks Value Added Reseller Pelf Infotech Private Limited, based in Pune.

Design to Manufacture Process Before DriveWorks

Before DriveWorks, IMA’s design to manufacture process required an engineer to design every part component by changing each dimension manually. They also had to give annotations and dimensions for every view in a drawing sheet. With so much manual input, the risk of costly human error in the design process was high.

DriveWorks is currently used by the engineering team internally and has been implemented in the design process of almost every product range at the company.

Implementing DriveWorks

Introducing DriveWorks has revolutionised the way IMA design their products. They have now configured DriveWorks for layout and component designing.

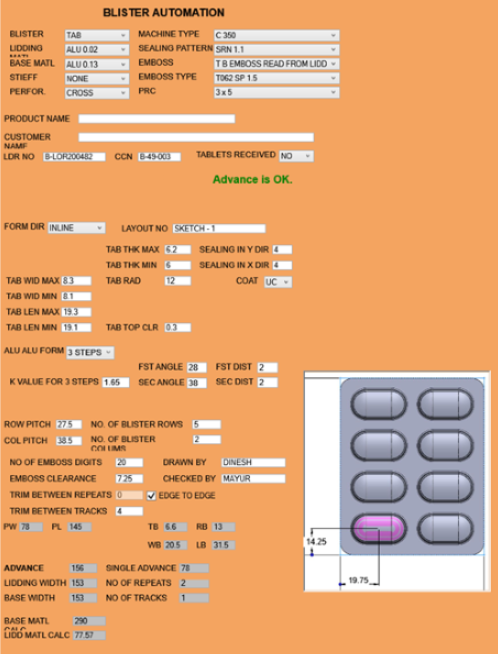

This means an engineer can now input the requirements for each individual specification into their form.

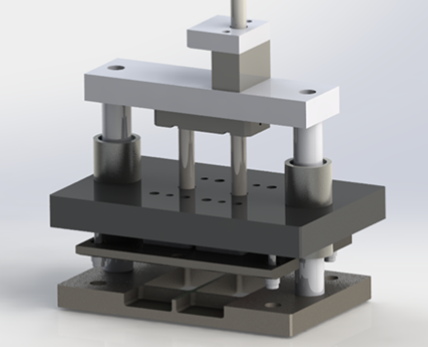

Once the form is completed, the new model along with its manufacturing data is automatically generated and ready to be sent to the manufacturing floor.

Speeding up the Design Process

Using DriveWorks Automation, IMA can respond to sales enquiries much faster, reducing their lead time significantly, opening up even more sales opportunities.

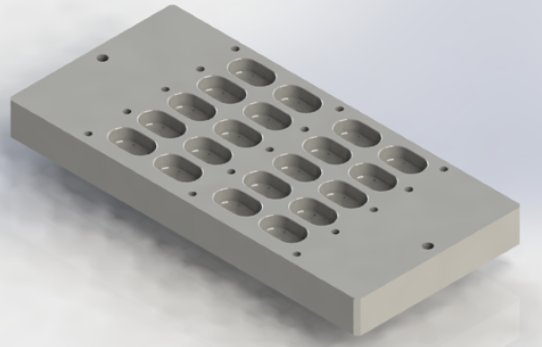

Cavity Die is a part of the design process that has benefitted particularly from DriveWorks. The Cavities are changed depending on each individual specification, for example they might be round, or an oblong shape.

This process is now specified and controlled through DriveWorks Automation, and the plate size is driven through variable parameters.

The outputs generated by DriveWorks are also now created from the Master Model.

Benefits for IMA PG

Since installing DriveWorks, IMA PG have seen a significant time reduction in their design process.

Before DriveWorks, design time peaked at four days and this has now been reduced to just one day. Costly manufacturing errors have also reduced significantly, and IMA PG are now at 80% drawing accuracy across their product line.

Mr Mayur Patil, Manager at IMA PG says:

“DriveWorks has played a crucial role in our day to day work, helping us to achieve two important goals; time saving and accuracy.”

Try DriveWorks Solo for free

Get instant access to DriveWorks Solo for 30 days. No credit card required.