Configuring a Sample HVAC

Products in the HVAC industry are often very specific and custom, and that’s where HVAC manufacturers can benefit from the power of a product configurator.

When designing an HVAC system, it is important to gather as much information as possible to meet the needs and the specifications of the facility.

Having the ability to engage with a customer in the design of the system with a product configurator such as DriveWorks can give your business a competitive advantage.

The DriveWorks Live website has many examples showing the latest DriveWorks technology.

Anyone can use these online configurators that were created using DriveWorks software.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom HVAC.

With DriveWorks 18, our team have added more 3D capability to bring the HVAC configurator to life.

I’m going to step through a series of options to specify the size of my HVAC. I’ll make my selection from the options provided.

With every change I make and every option I select, DriveWorks software is working in the background to update the model on screen, update selections and show an up to date price throughout.

Once I’ve completed my selections, DriveWorks will create all the manufacturing details automatically.

That includes the SOLIDWORKS 3D parts, assemblies and drawings, cut lists, BOM and much more.

Multiple Modules and Components

The HVAC configurator on DriveWorks Live is a strong example of adding and configuring multiple modules and components of an assembly together in DriveWorks.

The configurator steps through the different modules that make up the entire HVAC unit.

Notes within the different steps and modules help support a guided selling environment that a customer or salesperson can easily follow to make their configuration choices.

Each module will be configured on its own as part of the larger unit.

We will encounter multiple forms, rules and layers of design automation at work in this example.

Defined parameters and strong rules built in the background in DriveWorks are doing the heavy lifting.

Although we can’t see it, there is a lot going on with the design of this system in the back end once the entries have been made in the front end of the tool.

Dynamic Form Controls

The configurator makes it easy to design the HVAC unit, walking through the design step by step.

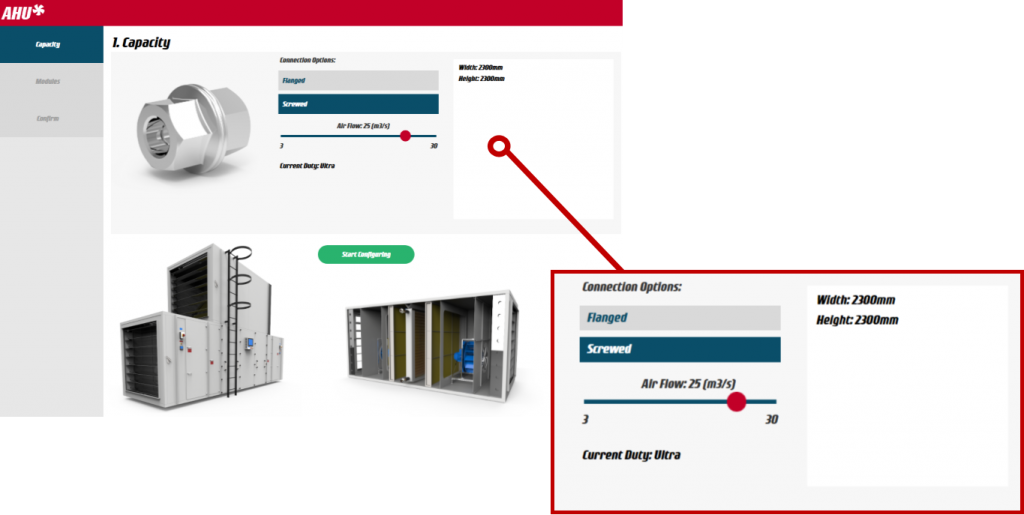

First, we need to set some specifications on the capacity and calculation of the airflow of the unit.

As forms define the user interface of a DriveWorks configurator, we will see various ways these are set up as we work through this example.

We choose our connection type in this first step by clicking on the options (screwed vs. flanged) and then use a slider tool to determine the airflow.

The system configuration will be updated as we move into our next steps.

Generation Tasks

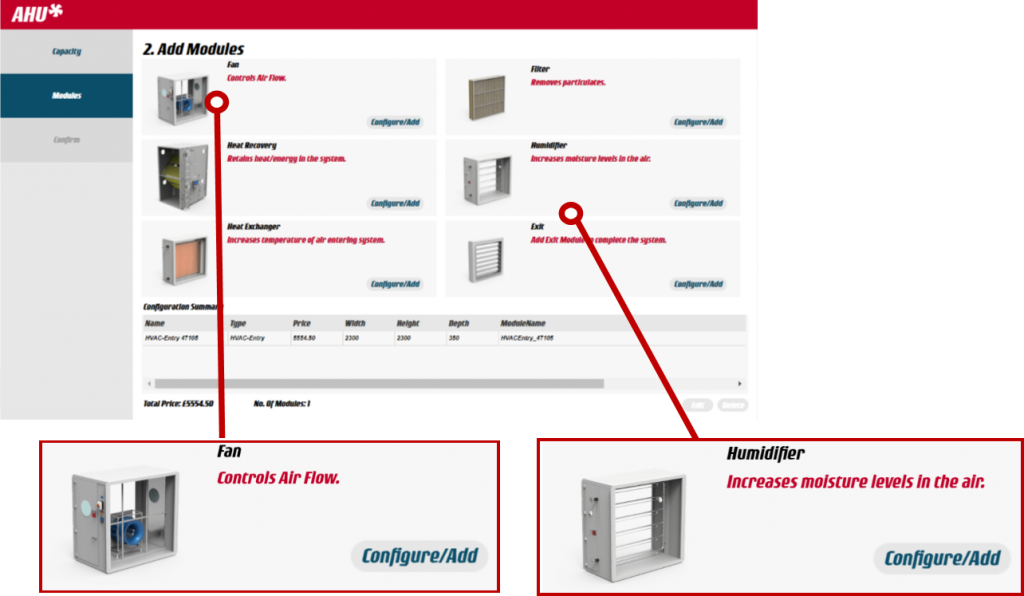

Once we have established our connection and capacity, we must now begin to add the different modules to the HVAC Unit.

Working through the simple dashboard of HVAC modules that have been created, we choose the modules we want to add one at a time by clicking on the image.

Once a module is chosen, a new set of DriveWorks form controls appear that are relevant to that module.

Changes are applied immediately when we add the module to our assembly and the price is also updated.

The choices we make on these forms are driving a brand-new design of this component because of rules that have been added in the background.

With DriveWorks Generation Tasks, we can add and configure the 6 separate modules individually to make up the larger HVAC unit assembly.

Specify Design Requirements

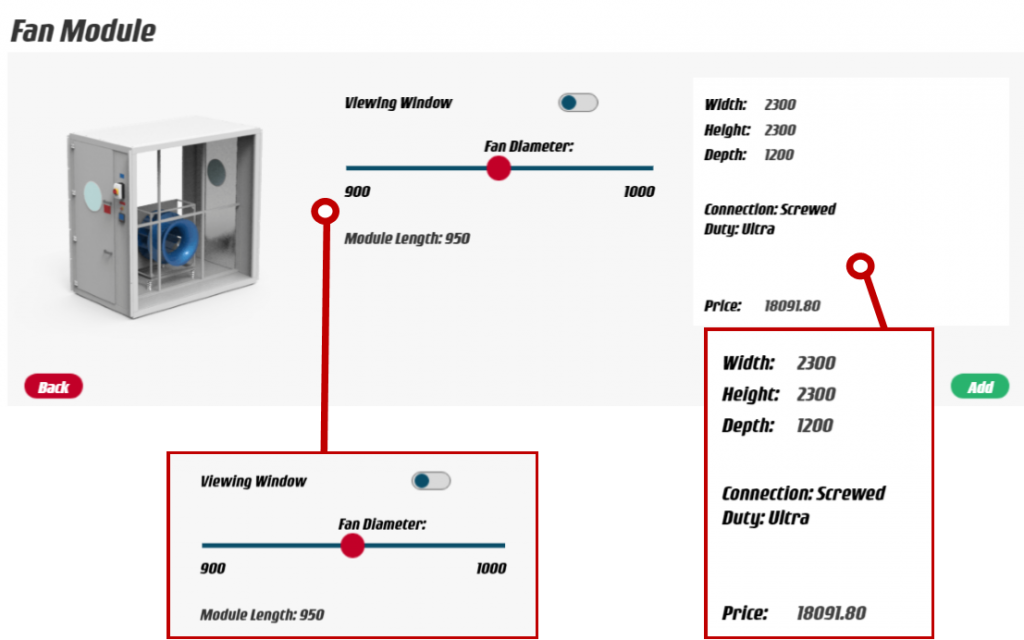

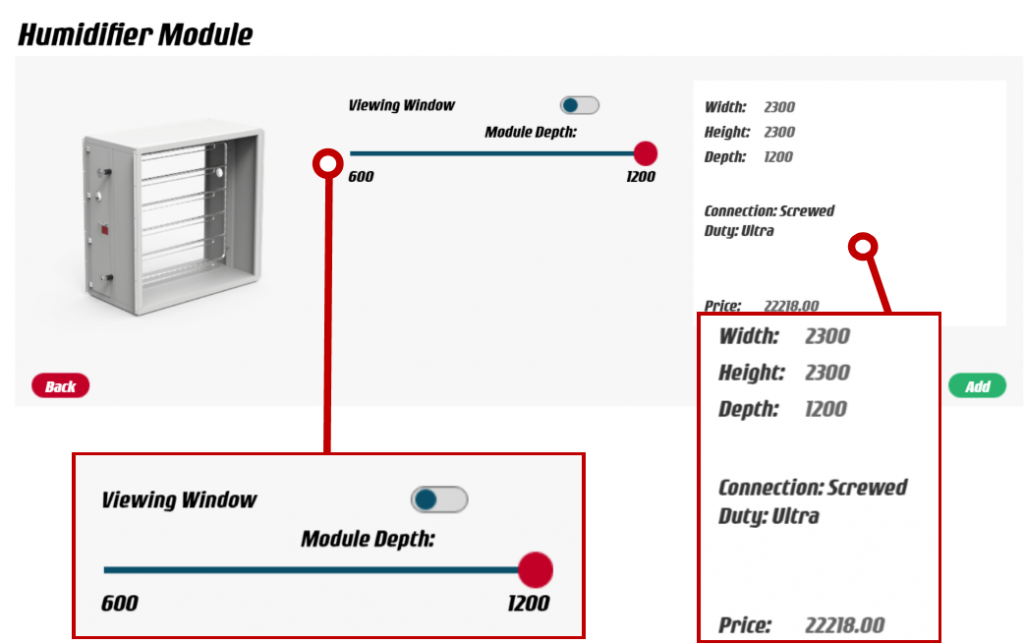

As we work through each of the 6 modules, we must specify the design requirements that we want for each module.

There are DriveWorks dynamic forms in place for each module. DriveWorks form controls are completely customizable so you can adapt and skin them to match your own branding, style and business needs.

In this case, the forms are mostly designed as a slider tool. In both the Fan Module as well as the Humidifier Module, we use the slider tool to choose the dimensions of the units.

Forms and rules work together in DriveWorks. The inputs of the forms are driven by the rules that have been created in the background.

The model and price are continuously updated. This automation happens throughout the configuration.

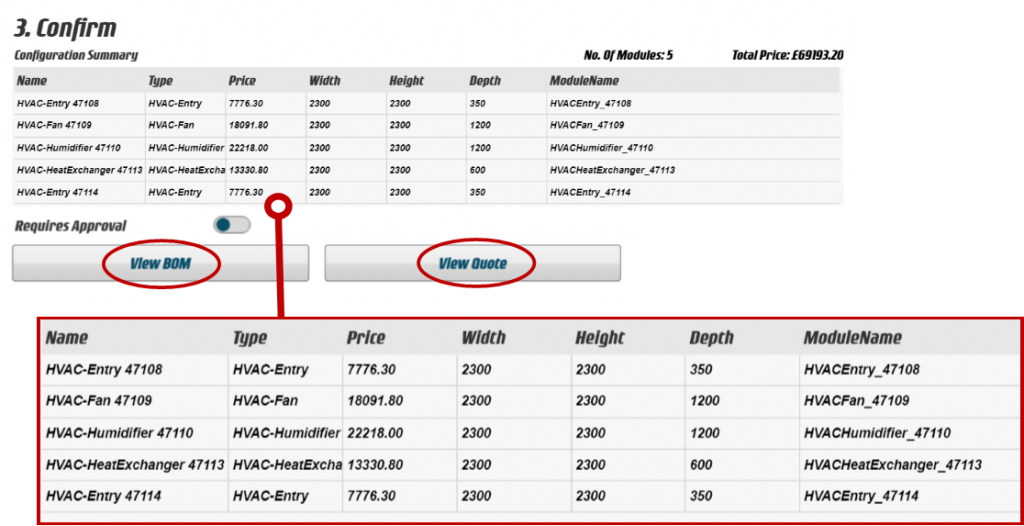

Order Review and Submit

As we complete the design of the HVAC unit, we can now review all the modules that have been added to our design.

This configuration summary page provides the list of the modules as well as the cost, dimensions, and description for each of them.

The configurator has been designed so that you can go back a step and make a change if needed – the change is then reflected in the model and the summary.

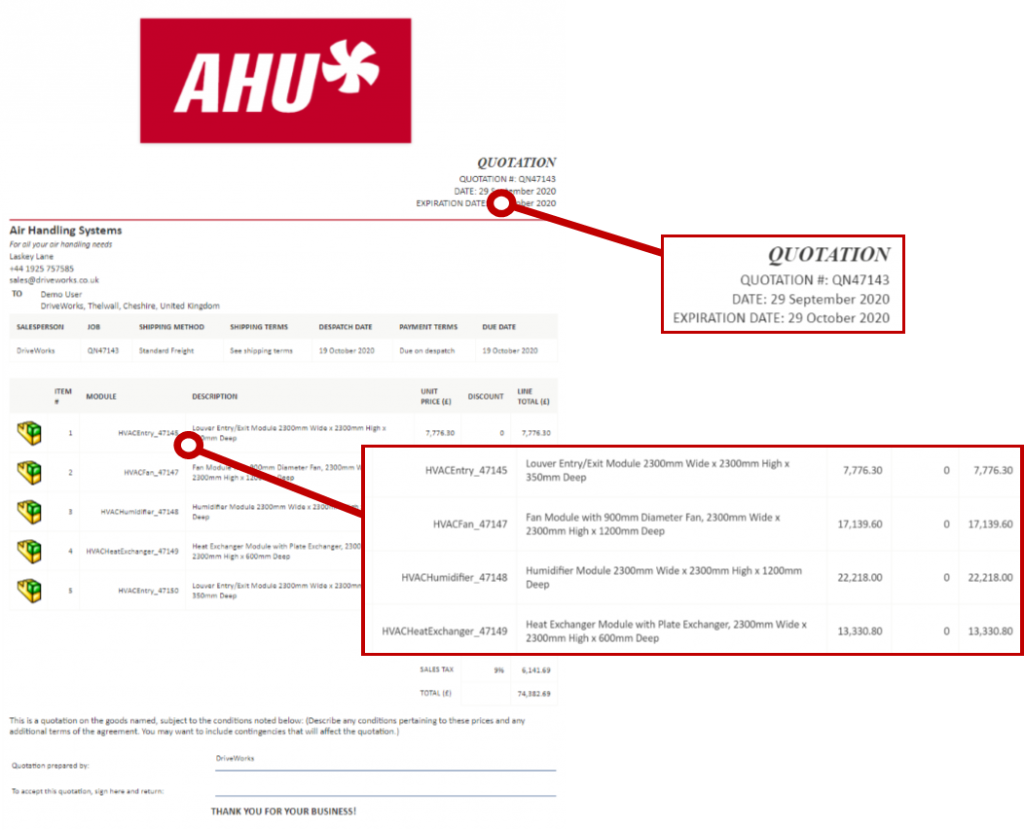

Automated Documents

DriveWorks also creates custom sales and manufacturing documentation for your order.

We can view the Bill of Materials and Quote for this order by clicking on the buttons in the configuration summary.

The quote provides a summary of the modules ordered during design as well as the cost for the order.

Once the order is confirmed and submitted, DriveWorks immediately starts generating the assemblies and a fully dimensioned drawing for review and for use in manufacturing.

All of this automation is a huge time saving for engineering. This fully automated process reduces errors, improves quality and allows product engineers and designers to focus on other areas of the business.

DriveWorks can easily pass information to and from 3rd party systems. This is possible as DriveWorks is built on its own fully documented API.

This makes it easy to integrate DriveWOrks with any of your company systems such as a CRM or ERP system.

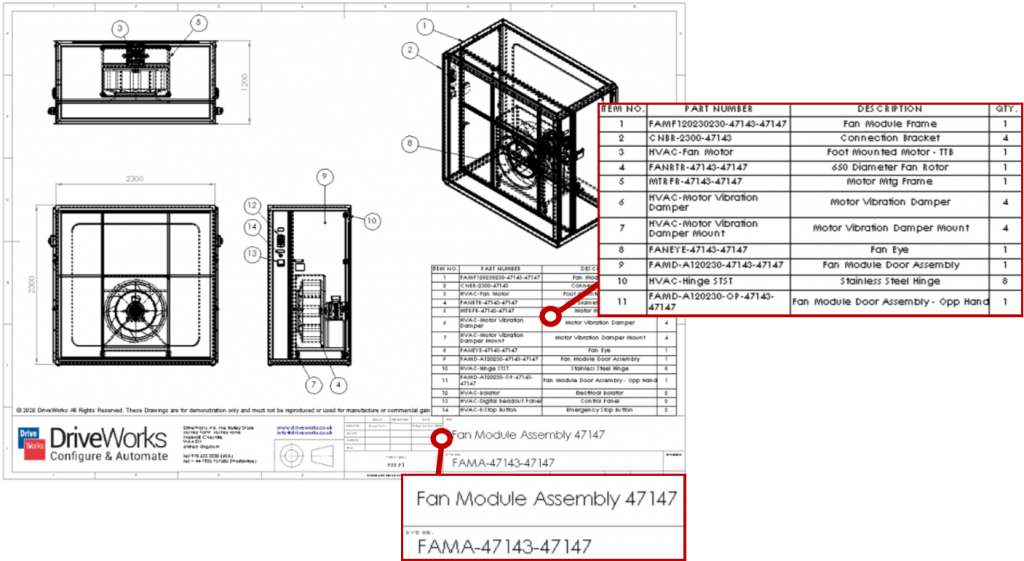

Drawings

In addition to receiving the order information and associated business documents, DriveWorks also automatically creates the SOLIDWORKS models for the HVAC unit and the detailed dimensioned drawings.

As the rules, logic and engineering knowledge have already been entered into DriveWorks, manufacturing can begin without engineers checking every detail and making changes to the design.

The drawings are labelled for easy identification. Below is an example of the fan module drawing that we configured in DriveWorks.

You can see that it has the part numbers as well as the descriptions for each part listed in the table on the drawing.

Having both the SOLIDWORKS models and drawings fully automated by DriveWorks, we have reduced the number of engineering hours needed every time a new order is made.

In addition to this, as the models are updated by DriveWorks, it also reduces the number of errors as well as expedited our time to manufacturing and meeting the customer’s needs.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This HVAC configurator is just one example of how DriveWorks can be used and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.