WEG

WEG reduce engineering time by 75% using DriveWorks design automation for SOLIDWORKS®

Challenge

WEG needed a solution to automatically create SOLIDWORKS drawings and manufacturing data. The solution also needed to ensure designers comply with strict engineering procedures and standards and the products meet ISO quality standards.

Solution

Calculations, databases and engineering rules are setup in DriveWorks by key-users, enabling designers to reuse captured engineering knowledge when they specify a new product. Designers specify custom products and automatically generate SOLIDWORKS drawings and manufacturing data.

Results

WEG have achieved a 75% reduction in time spent creating SOLIDWORKS drawings and manufacturing data and saw a return on investment after just 6 months. Designers now analyse and verify SOLIDWORKS data, rather than working on repetitive modelling tasks.

Company overview

Headquartered in Jaraguá do Sul, Brazil, WEG operate worldwide with branches in 36 countries and manufacturing plants in 12 countries. Their portfolio of over 600 product lines includes electric motors, generators, transformers, drives and coatings. WEG provide custom solutions for demanding and heavily regulated industry sectors, including oil & gas, marine, mining and energy.

WEG pride themselves on their continuous investment in innovation and team work. WEG are committed to efficiency, saying “Every day we work to make things better. All products, processes and developments are driven by the desire to increase efficiency.”

Challenge

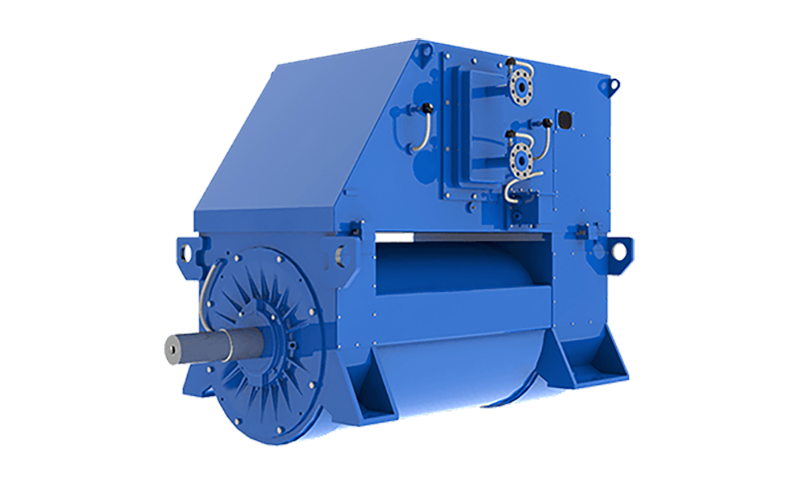

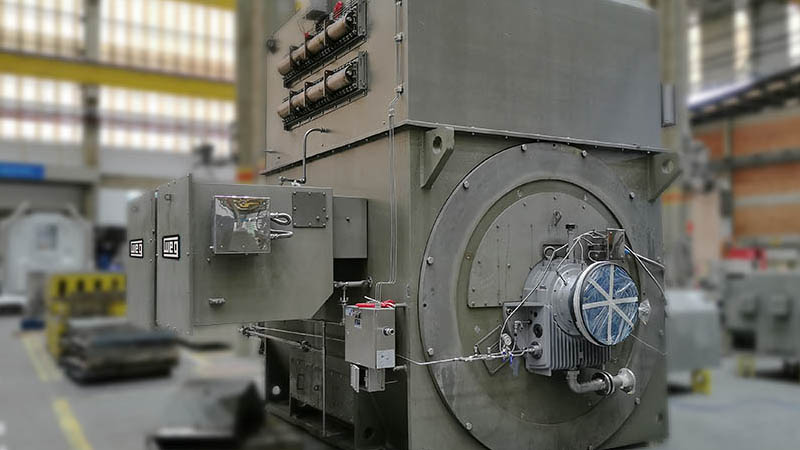

Custom power generators

Typically each contract means a new and often complex product needs to be custom designed, complete with detailed SOLIDWORKS manufacturing data and drawings.

The complexities of a power generator project for an oil platform are huge. As well as meeting the customer specifications, it must also meet a wide range of standards, such as ISO, engineering and manufacturing rules. The designers also have to consider specific rules relating to oxidation if the power generator will be based at sea.

Even with SOLIDWORKS, some customised WEG Energia projects took longer than desired to complete. These projects were liable to non-conformity and often did not include updates requested by manufacturing or the engineering department.

Simple implementation and maintenance

“We were looking for a way to automate our projects. Our first experiences were with algorithms and automated routines using the SOLIDWORKS API. We did achieve some good results but it still used to take a long time and involved many people from other areas such as IT. We thought about developing our own product configurator but SKA, our local SOLIDWORKS reseller, introduced us to DriveWorks. Developed for designers it is easy to set up and doesn’t require any specific programming knowledge”, says Roberto Vieira, WEG Energia designer.

With DriveWorks we can create all drawings and manufacturing data within one day. Using SOLIDWORKS alone this process used to take three to four days.

Carlos Jose Bastos Grillo – Engineering Manager

WEG

Solution

“With DriveWorks we can create all drawings and manufacturing data within one day. Using SOLIDWORKS alone this process used to take three to four days. Now the designer analyses and verifies rather than doing the modelling” says Carlos Jose Bastos Grillo, Engineering Manager.

Calculations, databases, engineering procedures and standards are set up by key-users, allowing designers to reuse this captured knowledge every time they need to specify a new custom product. Designers using DriveWorks can enter values into an interface that is easy to use and understand, and incorporating product improvements from across different departments. They are applied only once to the master product, ensuring that all future products respect the best existing practices.

Results

Return on investment

WEG achieved a return on investment after just six months on the generator carcass product, the first to be automated. Savings came from reducing rework, errors and development time. Currently 59 designers are DriveWorks users and around 14 automated products are available. Each product can generate several different variations of the same product family.

Employee onboarding

“DriveWorks is a very useful tool which facilitates the application of established criteria to our projects, the continuous improvement of our products and the maintenance of details. New designers without much experience are able to create new products with ease and quality, meeting the most rigorous standards and rules of WEG” emphasizes Vieira.

Try DriveWorks Pro configurator examples online

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.