HW Ventilation

HW Ventilation benefits from ten times faster design time by using DriveWorks Solo

Challenge

Before implementing DriveWorks, their lengthy design process required an engineer to draw every new product or variation of an existing product from scratch inside SOLIDWORKS.

Solution

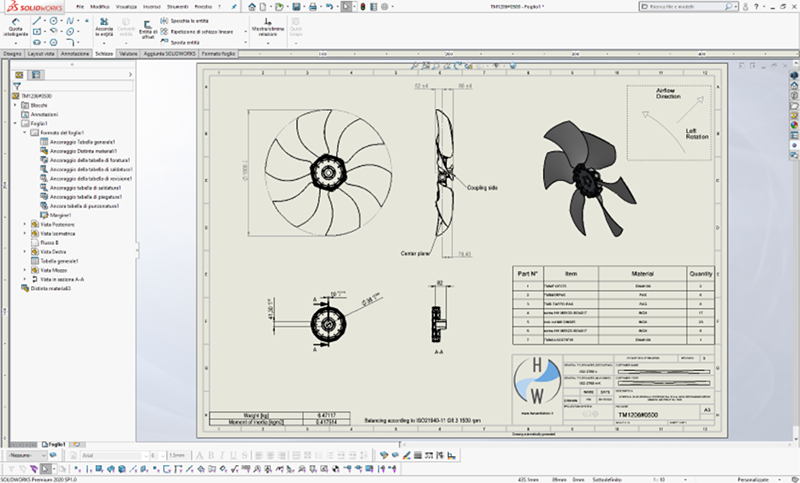

The DriveWorks Solo project also automatically generates brand new SOLIDWORKS® files and manufacturing data, such as bills of materials and 2D drawings, based on each individual form input.

Results

Automating this process now enables them to quickly generate 3D models of any type of fan, based on a set of standard variables, such as blade and hub types, fan diameter, material and colour rotation.

Company overview

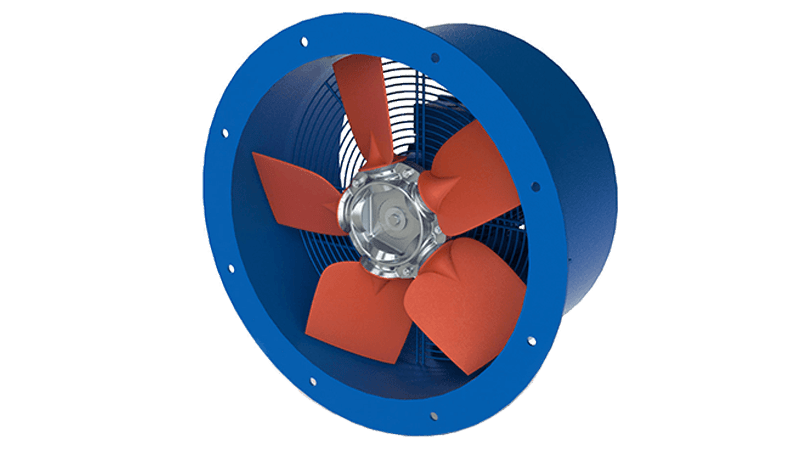

HW Ventilation, based in Rescaldina Italy is a leading company in the ventilation and air movement systems industry. They design, produce and sell axial impellers and ventilators for industrial use. This includes engine cooling systems, compressors, industrial plants and HVAC systems.

Challenge

Free up engineers from time-consuming, repetitive SOLIDWORKS modeling tasks.

HW Ventilation’s lengthy design process required an engineer to draw every new product or variation of an existing product from scratch inside SOLIDWORKS.

Our design process using DriveWorks Solo is 10 times faster than our previous manual process. Our engineers also don’t have to waste time making drawings and instead can focus their time on more rewarding projects

Matteo Morlacchi – Engineer

HW Ventilation

Solution

Automating the design process with DriveWorks Solo

Automating repetitive modelling tasks has enabled HW Ventilation to quickly generate 3D models of any type of fan, based on a set of standard variables, such as blade and hub types, fan diameter, material and colour rotation.

The DriveWorks Solo project also automatically generates brand new SOLIDWORKS files and manufacturing data, such as bills of materials and 2D drawings, based on each individual form input.

Results

Responding to customer demand

Implementing DriveWorks Solo has enabled HW Ventilation to respond to customer demand faster and with more efficiency, as they now spend a lot less time drawing the same but different designs.

Their customers now receive a drawing of the product they require almost instantly, and personalised quotes are sent out much quicker.

Future

Ready for the future with flexible and scalable software

Having achieved their target of reducing engineering time spent on repetitive and low value-add activities, HW Ventilation are looking to the future of what they can accomplish with DriveWorks.

Matteo Morlacchi says that their next step will be to scale up their current DriveWorks Solo projects to DriveWorks Pro and implement an online configurator that will enable their customers to configure products online.

Try DriveWorks Solo for free

Get instant access to DriveWorks Solo for 30 days. No credit card required.

Try DriveWorks Pro configurator examples online

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.