On Saturday we held our annual Summer Party. The DriveWorks team got together with friends and family for great food, homebrewed beer and DIY games!

Over the past few weeks, we have been spending our lunchtimes making our own games and it was great to see them all finished and have fun playing them on Saturday!

We’ve made splat the rat, cornhole, a giant hook and ring and the most ambitious of all, shuffleboard!

We also brewed some more beer, this time we went with some different recipes to the usual Automation IPA.

This year we made Configurator Pale Ale and Same but Different IPA. Both beers went down really well at the party, these are definitely recipes to keep!

Of course it wouldn’t be a DriveWorks party without some great food! This year we were treated to some delicious wood fired pizza from Stonebakers. They braved the rain to fill our Training Room with endless supplies of pizza.

We also had some Cheshire Farm Ice Cream, served from a trike! Oliver and Howie were more than willing to ride the trike around the party, taking ice cream to the people.

Alongside our usual pool tournaments, this year we had our DIY games to play too!

We made two cornhole sets, a giant ring and hook and splat the rat. The games certainly brought out the competitive sides in all of us and it was great fun playing the games we’ve all been building over the last few weeks!

The most popular game at the party was of course shuffleboard! After initial delays sourcing shuffleboard wax, we built this one in less than a week! What a great achievement to get it finished in time for the party and have so much fun playing it.

We’ll be bringing out the games at DriveWorks World 2020, look out for updates from us for news of the dates and location!

The only thing we couldn’t prepare in advance was the weather, and of course, being in the UK it rained! But we are used to it and some of us came very prepared!

Despite the rain, we had a great day enjoying drinks, food, games and laughs as a team!

We’re currently recruiting for a number of vacancies and we’re always on the lookout for talented people to join our team.

Check out our careers page to find out more about joining us!

Our annual DriveWorks Summer Party is getting closer and the games we have been building are nearly finished.

One of the games we planned to make was shuffleboard – ambitious, but we like a challenge!

Shuffleboard is a game we have played many times on our trips to the US, most recently we played it in Chicago during DriveWorks World 2019.

As it’s not a game that’s played in the UK, the biggest challenge wasn’t making the shuffleboard, it was sourcing the shuffleboard wax!

After lots of searching, trying to source shuffleboard wax in the UK, we called in Heather from the DriveWorks team who is based in Boston. Heather was able to find the wax easily in the US and had it ready for Glen and Maria’s recent trip to visit SOLIDWORKS.

After a few laughs from the TSA, Glen and Maria were able to bring the shuffleboard wax back to the UK and on Sunday afternoon the shuffleboard building began!

The Aim:

Simply slide, by hand all of your shuffleboard weights down the board without them falling off into the alley. Taking it in turns, knocking your opponient off the board, the winner is the one whos weights are furthest down the board.

Starting with a trip to the DIY store and a steady journey back, Glen and Thomas made a start on the DriveWorks shuffleboard.

Spending Sunday afternoon working on the table, our shuffleboard was nearly compelete.

The next challenge was getting the shuffleboard table to DriveWorks HQ.

With abit of help from the pick up truck and our willing volunteers, the table arrived as good as new!

After the final addition of some shuffleboard wax and numbers for scoring, our table is now in place and ready to play!

Look out for more photos of us playing the games at our summer party!

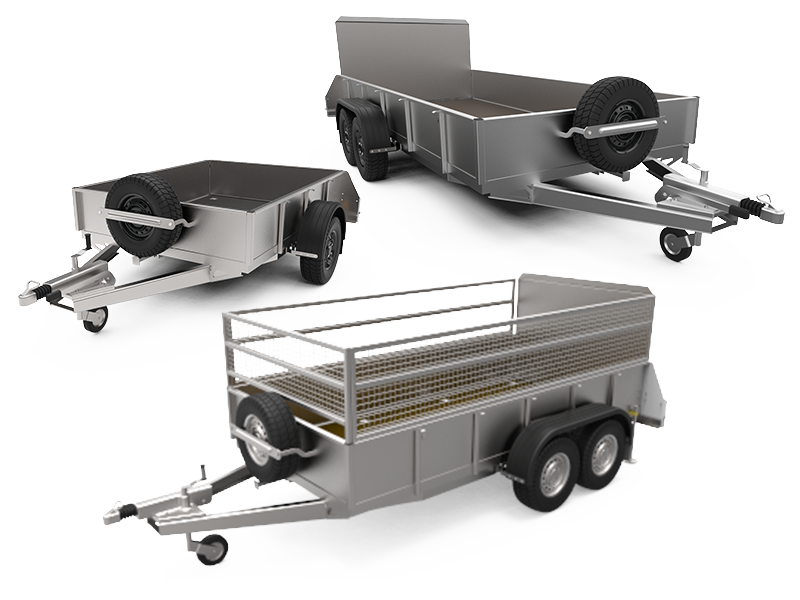

Our product configurator examples on DriveWorksLive.com are a great way to see what’s possible with DriveWorks, in a range of scenarios and industries.

DriveWorks product configurator software is used by companies of all sizes. It’s suitable for any industry where quotes or 3D files and drawings are part of the sales to manufacturing process.

Our configurator examples show how versatile and customizable DriveWorks is and provide great inspiration for your DriveWorks projects.

The software is not limited to what you see in our examples, with DriveWorks you build a custom solution that suits your needs and is easy to maintain and update.

We’ve recently added some new product configurator examples and updated some of our existing ones. Check out the changes we’ve made and have a go with some of the configurator examples below!

We’ve updated nine of our product configurator examples. The updated demos are now running DriveWorks 17, the latest version of our software. These examples showcase some of the new features in DriveWorks 17, especially the updates we made to DriveWorks 3D.

Get started with DriveWorks with a 30 Day Free Trial of DriveWorks Solo or contact us to find out more!

Before capturing your Master Model’s Assembly Structure inside DriveWorks, you need to decide which components need to be captured, and how to capture them.

The first question you should ask is, do any new models need to be created based on this component?

If they do, and Dimensions or Features need driving, they should be captured as a component. This will allow you to go on and capture Dimensions, Features, Custom Properties and Drawings against the component.

You can then build rules for these captured elements inside your project’s Model Rules.

The next question to consider is, does the component need to be swapped for another or have its configurations changed in the generated Assembly?

If the answer is yes, capturing the component as an Instance will mean you can build Rules that allow the component to be swapped, and have its configuration driven.

If a component doesn’t change, you don’t need to capture it at all. The component that exists in the master assembly will continue to be referenced by any generated assemblies.

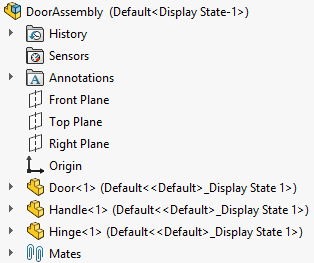

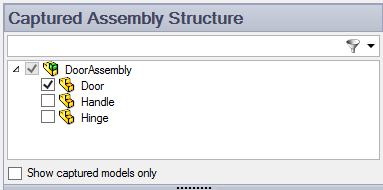

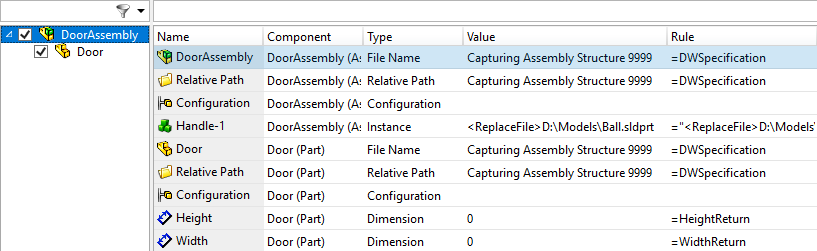

Inside SOLIDWORKS we have an Assembly called DoorAssembly with the Assembly Structure below:

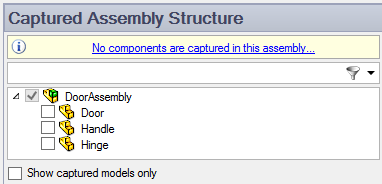

If we capture this Assembly inside DriveWorks Solo, the Captured Assembly Structure tab opens, and we need to decide what to capture inside the Assembly.

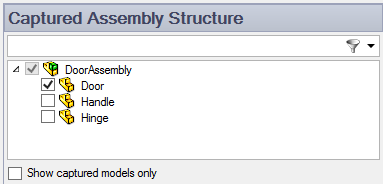

We want to be able to drive the Door Part’s dimensions and generate new files based on a Master Part. This means we need to capture it as a component by checking the associated checkbox.

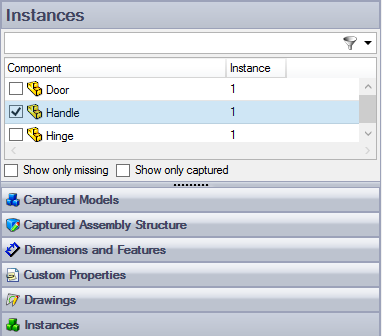

In any new DoorAssembly files that we create using DriveWorks, we don’t want new Handle Parts to be created. However, we do want to be able to swap in existing Parts from a library.

To do this, we can choose to capture the Handle Part as an Instance.

With the DoorAssembly open, clicking on the Instances tab will show all the components that can be captured as Instances, clicking on the checkbox next to the Handle component will capture it as an Instance.

The final component to consider is the Hinge. We can leave this uncaptured as the component can’t change.

The Hinge Part being referenced by the Master DoorAssembly will continue to be referenced by any generated DoorAssembly Models.

You won’t need to build any Rules for the Hinge Part and running the Project won’t generate any new Hinge Parts.

Inside your Project’s Model Rules, swap the Handle Part for a different SOLIDWORKS Model and reference the existing Hinge Part in any generated models. This will allow you to create a new version of the DoorAssembly and Door Part.

Markets are changing, and customers are expecting more from the products and services they are buying. Consumers want products faster, cheaper and easier than ever before, without compromising on quality.

This is presenting a challenge for many buisnesses.

To meet demand, manufacturers are looking to automation.

Design automation is enabling businesses to turn around proposals quickly, design and manufacture efficiently and deliver on promises consistently, all whilst maintaining a healthy profit.

By automating time-sensitive and often repetitive activities, businesses can focus on innovation and adding value to their products, improving throughput and quality to meet customers’ requirements.

Becoming smarter, agile and much more flexible means manufacturers are able to achieve increased productivity and stay competitive.

According to Digitalist Magazine, “manufacturing is transforming from mass production to an industry characterized by mass customisation”.

Customer expectations are growing, and the demand for personalisation and customization is rising. Unlike the second industrial revolution, customers don’t want mass produced identical goods. They want value-adding customised products.

Gartner emphasizes that the goal of digitalisation is to create and deliver new value to customers, not just to improve what is already being done or offered. To adapt to this, enterprises and manufacturers are changing strategies, embracing new technologies and ‘going digital’.

By offering customers exactly what they want, businesses are increasing demand for their products and increasing revenue.

The Annual Manufacturing Report 2019 suggests that digital technologies are driving modern manufacturing machinery, allowing for mass customisation. Modern customisation is bringing change, allowing even small companies to serve a wide variety of customer demands on the production line.

Offering customized products and services is a great competitive differentiator, leading to more sales, higher revenues, and happy customers.

However, manufacturers offering custom products are often putting their engineers under pressure. They’re squeezed to create proposal documents and drawings as fast as possible. This leads to best guess costings, for orders that aren’t guaranteed.

Engineering departments are wasted on tasks that could be automated. They have less time to update drawings and carefully check every detail. Jobs are then left open to errors, rework, backlogs and delays. All of this can affect profit margins and damage reputation.

With DriveWorks, many manufacturers are already seeing the benefits of design automation.

Automation is freeing up engineers, giving them more time to focus on improving product quality and developing new products.

Sales teams are becoming more proficient meaning customer inquiries are being dealt with faster and throughput is increasing.

Automation is leading to more orders, reduced operational overheads, and better customer service one step at a time.

Ideal for configuring designs that are the Same but Different, DriveWorksXpress provides entry-level Design Automation inside world-leading, 3D CAD design software, SOLIDWORKS.

Use it to create multiple variations of SOLIDWORKS Parts, Assemblies and Drawings quickly and accurately.

Save time, reduce repetitive tasks and minimise costly errors.

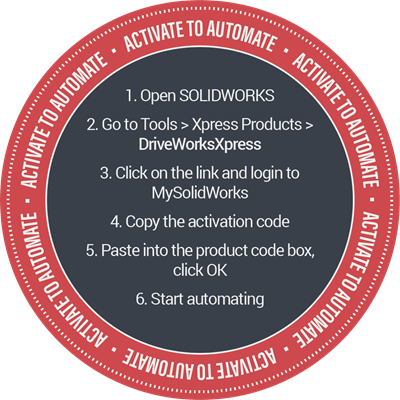

DriveWorksXpress is the time-saving Design Automation tool included free inside every licence of SOLIDWORKS, all you need to do is activate it.

This is the fourth blog in our new digital transformation series. Each week we will be sharing our insights about the importance of embracing digital transformation and automation. Keep reading to learn more!

With Digital Transformation businesses are working smarter. Technology, software and automation are allowing companies to focus on future opportunities and innovation.

Technology is increasing efficiency, improving accuracy, streamlining business to consumer relations, boosting speed, and allowing for a wider range of products.

Digitalisation doesn’t always look the same. It can be different depending on industry and organisation.

For some, the aim may be to simply automate lengthy manual processes. Jobs that previously took hours, days or even weeks to accomplish can now be achieved within minutes.

While for others, the goal is to create a smart factory. Transforming entire factories so they become digital and connected, with machines that can improve processes through automation and self-optimization.

The European Software and Services Initiative, NESSI report that Industry 4.0 will rely on technologies to develop intelligent cooperative systems with increased data sharing and analytics capabilities.

Using DriveWorks software enabled A-LINE to create up to 200 designs per day, giving them a huge competitive advantage in the marketplace.

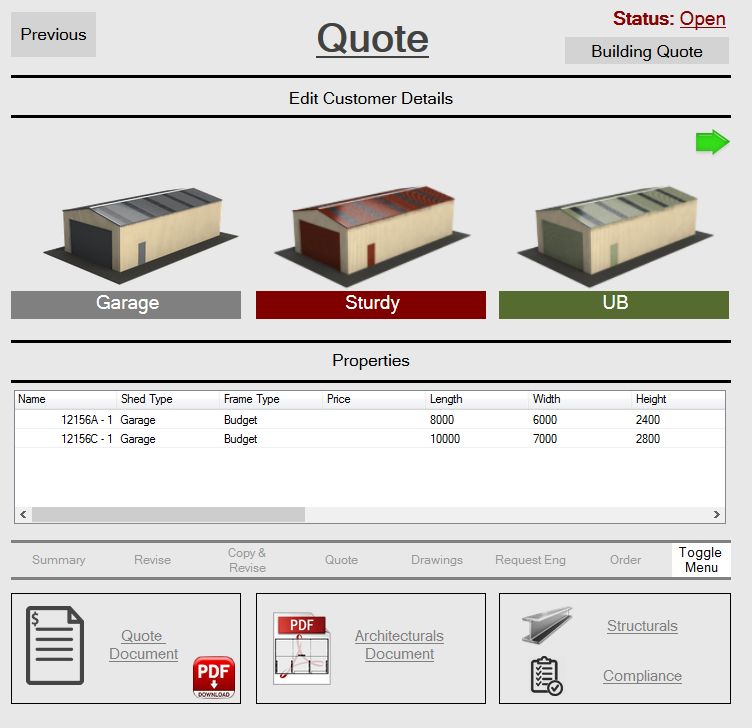

The system they’ve built in DriveWorks provides an easy to use homepage for their sales team, which provides instant quotes and drawings for the customer.

It also has a quote management area to help the sales team manage their quotes in one place, quickly and easily.

By replacing a time consuming manual quoting processs with automation, A-Line saved time, saved money and reduced errors, without compromising on quality or professionalism.

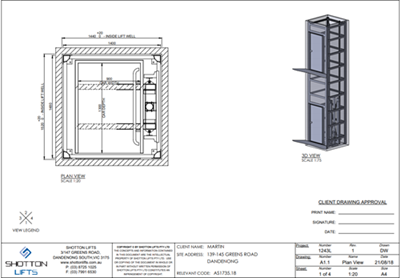

Both Rademaker and Shotton Group have seen great time savings with the use of implementing software into their business processes.

Rademaker, a company providing solutions for the food processing industry found that with the use of DriveWorks, they reduced engineering time to less than 15 minutes.

With a new Zero Effort Engineering process, the engineer only needs to fill in the specifications of a machine and the 3D models, drawings and bill of materials are automatically generated.

This reduction in engineering time not only helped to achieve targets but also increased flexibility, variants, functionality and the number of options they can handle.

Through the introduction of software and automation, the Shotton Group cut the process of creating product sales documentation from half a day down to 30 minutes.

Engineers’ time previously spent on repetitive tasks can now be used on more valuable tasks such as R&D.

For the Shotton Group, the integration of software has saved them time, improved customer satisfaction and taken them a step close to achieving objectives.

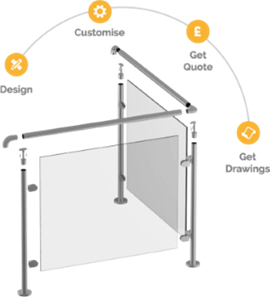

DriveWorks customer, F.H.Brundle are a wholesaler of steel products, stocking over 8,500 products. As they are adding new products all the time, it was important for them to find a solution that could be set up and managed by themselves.

Using DriveWorks, F.H.Brundle created their own online configurator for internal teams, distributors and customers.

Since the introduction of software, F.H.Brundle’s businesses processes now allow customers to configure systems to their own dimensions, creating accurate quotes and detailed drawings in minutes. Saving their customers hours of work and helping to eliminate mistakes.

The Entrepreneur Europe agrees that done right, a digital shift can lead to increased savings, happier customers and better prospects in both the short and long term.

Read more about how DriveWorks software has helped our customers to adopt and benefit from digital transformation

“Using DriveWorks enabled us to create up to 200 designs per day”

– Craig Barker, Director, A-LINE

“Order-engineering has gone from 2 hours to 15 minutes.”

– Rob Beffers, Manager Integrated Process Control, Rademaker BV

“Customers can get a quote anytime they want it, 24/7/365.”

– Richard Twiddy, Design Office Manager, F.H.Brundle

“We’ve reduced the amount of time taken to complete forms from half a day to only 30 minutes.”

– Martin Clenick, Engineering Manager, Shotton Group

“DriveWorks has allowed us to automate the routine processes that we undertake day in and day out.”

– Dr Scott McGovern, Digital Engineering Lead, Laing O’Rourke

“We now have more time to focus on our workflow and business analytics ”

– Adam Baker, Operations and IT Manager, BKW Instruments

This is the third blog in our new digital transformation series. Each week we will be sharing our insights about the importance of embracing digital transformation and automation. Keep reading to learn more!

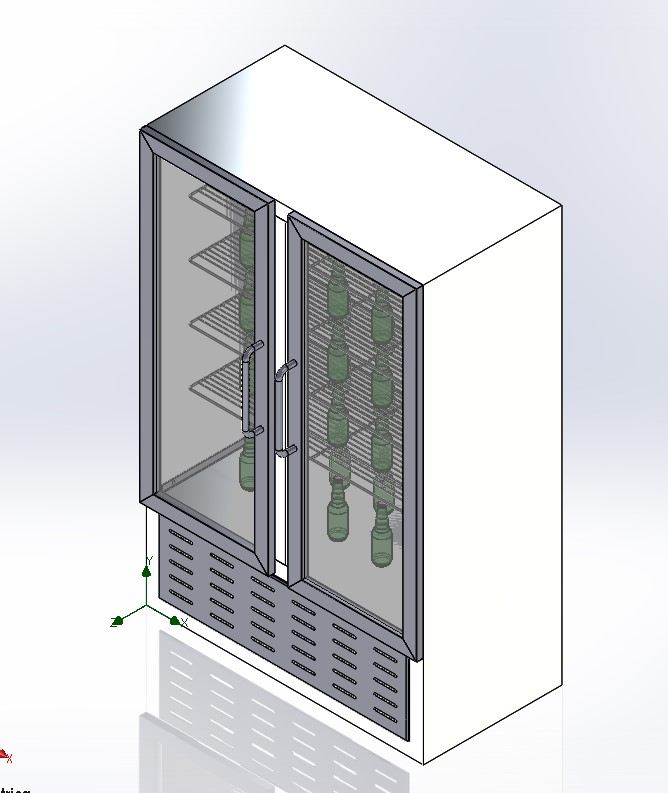

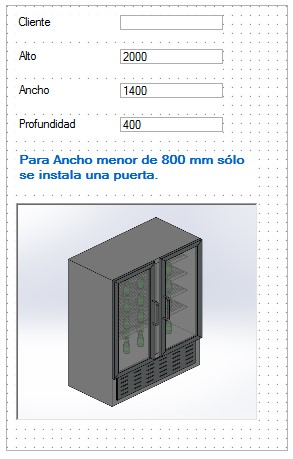

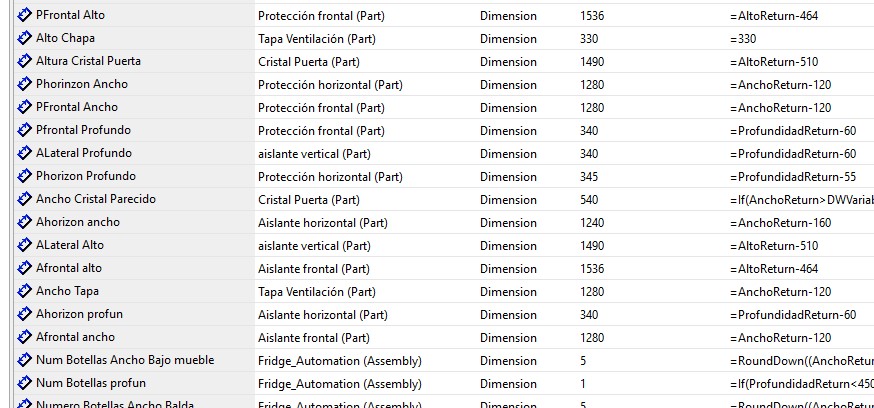

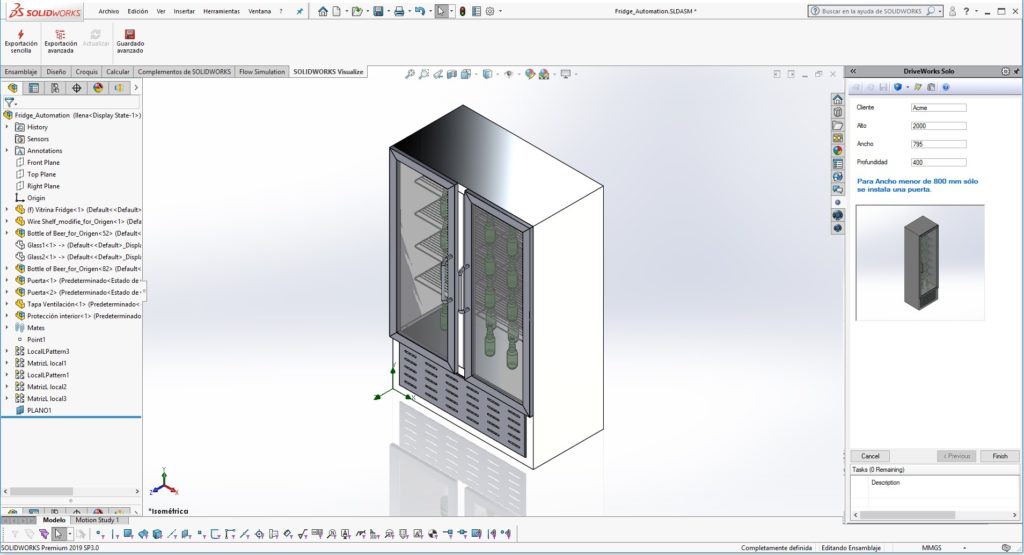

Este blog tecnico de Origen explica todo que necesita saber de crear un proyecto configurador en DriveWorks Solo.

En muchos sectores, como el de las cámaras frigoríficas, es común encontrarnos que, teniendo un producto bien definido, debemos adaptarnos a los requerimientos del cliente.

En nuestro día a día escuchamos frases como “la cámara debe ser más baja”, “quizás requiere un ancho especial”, “tal vez más estrecha”, …

Este escenario provoca un trabajo extra con cambios de diseño evidentes y un cuidado máximo a la hora de validar documentación. Dedicando un tiempo elevado en revisar que ningún elemento del proyecto está obsoleto o no contempla los cambios deseados.

Con la combinación de las herramientas SOLIDWORKS y DRIVEWORKS, únicas en el sector, este reto de generar proyectos parecidos a los existentes se consigue automatizar y simplificar, siguiendo cuatro sencillos pasos. El camino hacia mi configurador ha comenzado.

Como inicio, nos basaremos en un primer modelo estándar compuesto de todos los diseños 3D, planos y documentación 2D, planos de fabricación y ficheros auxiliares para máquinas de corte, listados, etc. Mi cámara de frío estándar.

A continuación, definimos los datos de entrada que han de añadirse al proyecto como inputs. Éstos pueden ser de naturaleza diversa como el código de mi proyecto, las dimensiones máximas, tipo de acabado y tantas como necesitemos. De este modo los parámetros que definirán mis futuros diseños de cámaras de frío quedan definidos.

Casi para terminar definimos las reglas. Éstas me permiten modificar los diseños estándar tras señalar unos datos de entrada determinados. La experiencia de quien conoce bien el sector de las cámaras de frío hace que este paso sea rápido, seguro y sencillo.

Generando el modelo. El sistema crea el nuevo modelo de modo automático. Se obtiene una colección de documentos nueva, única e independiente de cualquier otro diseño. La información de diseño y fabricación de mi nueva solución de cámara frigorífica está generada. Así de fácil.

Con este sencillo proceso, generamos ventajas apreciables de impacto inmediato en SU negocio en la configuración de cámaras frigoríficas.

Every year the DriveWorks Team gets together for our annual summer party where we enjoy an afternoon of food, drinks, games and fun with family and friends.

This year we have set ourselves the challenge of making our own games to play on the day!

A few weeks ago we held a vote to decide which games we’d most like to build over the coming weeks, we decided on:

After a number of planning sessions and a trip to the DIY store, the game building is now well underway!

The famous DriveWorks Automation IPA has been a key part of previous DriveWorks parties and was a popular choice for our delegates at DriveWorks World 2018!

This year Ben, one of our software developers and chief brewer, has created two batches of new special brews ready for this year’s party and we can’t wait!

Make sure you keep on following for further updates on our progress!

In our blog, How Digital Transformation is Changing the Manufacturing Industry, we explored emerging trends in digital transformation and industry 4.0, looking at how the manufacturing industry is being transformed by a revolution of smart factories, automation and big data.

Powering this digital transformation is the development and integration of software.

Going digital is all about streamlining business processes, driving productivity and innovating one step at a time. Entrepreneur Europe reports that the point of digital transformation is not to take companies from paper processes to hyper-advanced and complex digitalized alternatives. Instead, many components of digital transformation are subtle and take time.

A lot of businesses fear the changes digital transformation brings because they think it means updating entire infrastructure with new systems, new technology and new processes, however, digital transformation isn’t just about transforming factory floors with robots and automation.

Alongside these devices, software is developing too, supporting the introduction of smart, tech-driven solutions and playing a key role in transforming industries.

A great example of the impact software can have is how Laing O’Rourke have digitally transformed the bridge industry.

Software enhances, expands, and restructures the way organisations work, influencing industries and having a huge impact on digital transformation throughout manufacturing.

Laing O’Rourke collaborated with Tony Gee and Cambridge University to develop a unified digital delivery process for the entire bridge industry.

The research group have introduced standards to simplify a complex process. The outcome is a set of best practices for manufacturing, assembly and design, to ensure consistent data formats and reduce manual processes required between stages.

Using SOLIDWORKS 3D CAD and DriveWorks Design Automation and Configurator software, Laing O’Rourke have built tools to digitise bridge design.

This project has dramatically reduced the time taken to reach the final design, construct and complete a bridge and has transformed the entire bridge industry through the use of software.

The time savings could see bridge designs produced in days or weeks instead of months and years. Rolling out the project will increase efficiency and capacity across the entire industry.

In order to be successful, software needs to work in harmony with each other and with current business processes.

To streamline processes, more and more companies are using Enterprise Resource Planning (ERP) systems to manage integrated applications.

ERP connects core business processes and improves efficiency of production, as well as the operation of the entire business.

BKW Instruments, a company who provide equipment and instruments to various industries in the UK, developed a web-based platform that allows their company to interact with the SYSPRO ERP system securely from any device, anywhere in the UK.

The application BKW developed was created in DriveWorks and enables them to organise and speed up everyday business processes and tasks.

Logging and processing sales enquiries has gone from 3 hours to 30 minutes and their internal sales team are creating quotes twice as fast as before, resulting in a 100% increase in productivity!

Their customers are benefitting from quicker turnarounds and better service too.

BKW has successfully met all their business objectives, resulting in significant time savings, increased productivity and better customer experiences.

Digital transformation is changing the way companies work across all departments. Digital transformation provides a perfect opportunity for businesses to replace traditional ways of doing business with other sophisticated digital technologies to embrace the new digital world.

The role of software in the manufacturing industry is only going to continue to grow. By embracing new technologies and software, businesses can increase efficiency, improve accuracy, streamline business to consumer relations, boost speed, and allow for a wider range of products.

This is the second blog in our new digital transformation series. Each week we will be sharing our insights about the importance of embracing digital transformation and automation. Keep reading to learn more!