We’re taking a break from our Tech Team Thursday webinars over summer. But we’ll be back on Thursday 6th September with a great new series!

These webinars are our opportunity to share the Tech Team’s knowledge with our DriveWorks Pro Customers – with an Active Subscription Support Contract – and Reseller Applications Engineers.

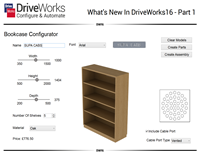

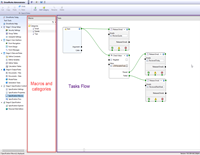

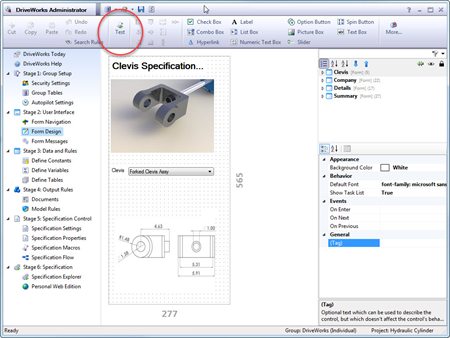

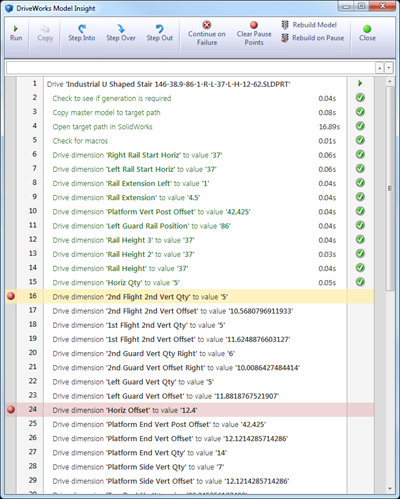

In our new series, Mike, a Technical Specialist at DriveWorks, will take a look at some of the cool new features and enhancements in DriveWorks 16 and he’ll show you how to use them!

Learning more about DriveWorks will enable you to get the most out of the software and throughout the webinars you can ask questions to advance your knowledge.

This is a great opportunity for you to catch up on any sessions you may have missed by visiting the technical webinar library in the DriveWorks Community.

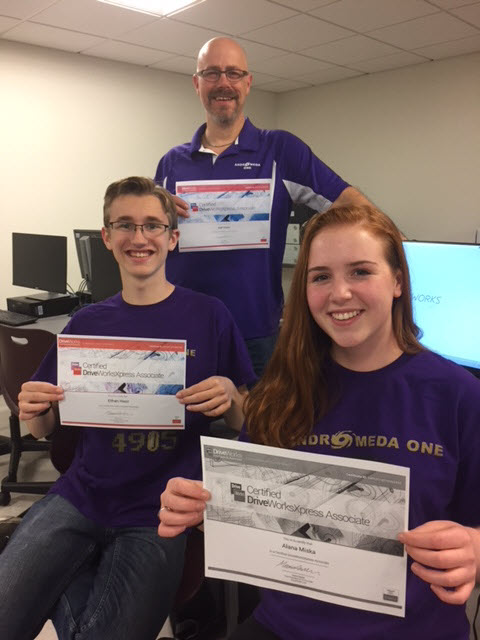

Here’s a few of the great titles from our latest series: