As part of our annual personal development plans, we gather feedback from the DriveWorks team about skills they would like to learn or courses they would like to take part in.

This year, a few of the team mentioned that they would like to attend a project management training course. Glen and Maria felt that a course like that would benefit everyone here, not only to help us to manage our own work projects but also to provide good documentation about how best to manage a DriveWorks project.

So, back in November, the whole DriveWorks team took part in a project management training course. We all learnt a lot and came up with examples of how we would put the techniques learnt to good use in our day to day roles here at DriveWorks.

To put the skills we had learnt to the ultimate test, we decided to organise our entire Christmas party.

In previous years we have been to a local hotel and joined a shared Christmas party, all organised by the hotel. All we have had to do is dress up, show up, eat good food, drink beer and dance.

This year though, we hired some rural cottages for the weekend. We had an entire weekend away to organise, from Thursday evening to Sunday morning. To do that well we split into 5 different teams:

Everyone chose which team they wanted to be part of. The company was mixed up and we all got chance to work alongside different people doing tasks that were very different to our ordinary roles.

There was a lot to organise but each team used the frameworks and processes we had learnt in our project management training to plan well.

We spent lunchtimes planning for the event, with each team working hard to contribute towards it.

Logistics were planning how the team and the equipment would get to the venue, as well as creating rotas for throughout our stay.

The food team calculated quantities and cooking times and gathered preferences and dietary requirements.

The entertainment team came up with quiz questions and awards, gathered props and games and created playlists.

The decorations team got creative, painting a sign, 3D printing keyrings and creating personalised coasters for everyone.

The bar team had the most important job, and they even brewed their own beer, Automation IPA!

Each team had thought of every little detail and the weekend was a huge success.

On Thursday evening we arrived at the snowy estate, unpacked, enjoyed a giant lasagne together and had a pretty competitive quiz!

The main event each team was planning for was the Christmas party on Friday evening. After a full day of preparations, we all gathered in the party room to enjoy a delicious meal together, have fun in the photobooth, sing karaoke (some better than others!) and dance until the very early hours of Saturday morning.

It was lots of fun and so rewarding to see all of our planning come together into a brilliant celebration!

We hope you are enjoying the festive season too and we’re looking forward to putting our project management skills to good use again throughout 2018!

Happy holidays everyone, from the DriveWorks team!

As part of our performance and growth strategy, we take a proactive approach to people and team development. Having achieved Bronze accreditation in 2014, we recently applied for the 3-year re-assessment against the Investors in People standard and we’ve now achieved Silver accreditation.

Organisations that meet the world-recognised Investors in People Standard reflect the very best in people management excellence. Underpinning the Standard is the Investors in People Framework. Based on 25 years of leading practice, the latest research and workplace trends, the Investors in People Framework is organised around nine key indicators of high performance, each with three underpinning themes.

The 9 key indicators are:

To achieve accreditation, organisations are assessed against these themes and indicators. Assessment is carried out using surveys, interviews, meetings and observation. The accreditation awarded represents the current level achieved and the standard can be used to facilitate ongoing development of people management practices.

The assessment included benchmarking the company against all of these standards and DriveWorks exceeded the industry average across all themes.

We are proud of our people, they’re a team of hardworking, brilliant, honest and passionate people who all go the extra mile. We will continue to invest in our people and work together to execute beyond expectation.

Over the course of SOLIDWORKS World, you’ll join more than 5,000 of your peers and select from more than 200 breakout sessions on a range of topics. Make sure you learn about Design Automation and CPQ. Even if you’re already automating, there’s always something new to see and learn!

Here’s a few of the design automation and configurator presentations that are taking place…

Date: Wednesday 7th February 2018

Time: 10:30am – 12:00pm

Presenter:

Tom Wormald – Technical Specialist, DriveWorks Ltd

Category: MCAD: Design Automation

Room: 406B

DriveWorksXpress is the Design Automation tool included in every license of SOLIDWORKS. It’s great for creating variations of products that are the same but different. Create a DriveWorksXpress configurator from scratch and start your DriveWorksXpress Certification in this hands-on session.

Learn how to create DriveWorksXpress forms linked to your models, automate SOLIDWORKS geometry and configure model variations based on your rules. See how automation can improve your work, create your own DriveWorksXpress configurator and take the first steps to getting certified.

Date: Tuesday 6th February 2018

Time: 4:30pm – 5:30pm

Presenters:

Derek Lawson – DriveWorks Technical Team Leader, Computer Aided Technology

Ryan Dally – Product Manager, Computer Aided Technology

Category: MCAD: Design Automation

Room: 411

This hands-on training will prepare attendees to automate their designs using DriveWorksXpress, which is included in every seat of SOLIDWORKS. Topics include planning for automation, leveraging your existing models, and growing your automation. Electronic manuals and training files are provided as well as live step by step training.

Date: Wednesday 7th February 2018

Time: 10:30am – 12:00pm

Presenters:

Justin Maxwell – Senior Application Support Engineer, Computer Aided Technology

Judy Marlo – Application Engineer, Computer Aided Technology

Category: MCAD: Design for Manufacturing / Assembly

Room: 411

This session demonstrates the SOLIDWORKS Xpress Tools. It provides an informative look into tools all SOLIDWORKS users have. Xpress tools are lightweight versions of the larger tool. There are four utilities: are DriveWorksXpress, DFMXpress, SimulationXpress, and FloXpress.

Attendees will learn how DriveWorksXpress can make design changes simple and easy. DFMXpress can help catch mistakes to the manufacturing process. SimulationXpress will determine effects of force, pressure, and generate reports to document results. FloXpress shows how a fluid will flow through a model.

We attend SOLIDWORKS World every year and the best part is always meeting new people and catching up with familiar faces.

Pop by and see us at Booth #511 in the Partner Pavilion to try out our sales configurator software on our kiosk, designed in SOLIDWORKS and made by the DriveWorks team.

You’ll also find us at the Annual SOLIDWORKS User Group Network Meeting.

See you in Los Angeles!

In this blog Paul Gimbel, Business Process Sherpa at Razorleaf, discusses how they use intelligent rules in DriveWorks to help their customers extend their implementations.

It’s no secret that at Razorleaf, we do a lot of DriveWorks implementations and every implementation is always the start of something larger for our clients. There is no such thing as a completed automation project because you will always want to add new options, new products, new outputs, just adding more and more value. With every implementation being totally different, how can we help our clients to extend their implementations moving forward? Easy, we use intelligent, generic, reusable rules.

I can hear your question right now. You’re thinking, “OK, Paul, what in the blazes does that mean?” Fair enough. That does sound like a bunch of business lingo bingo. The bottom line is that if we intelligently plan for what we will want to change or grow, we can use functions in DriveWorks that are completely independent of the specific control or variable or SOLIDWORKS dimension that they are determining. Make these rules smart enough and Ctrl+C then Ctrl+V will be all you need to expand your implementation. So at this point, you’re either very curious or very confused. I’ll try to address both.

First of all, what do we mean by generic? And why do I ask so many questions when I’m supposed to be answering yours?

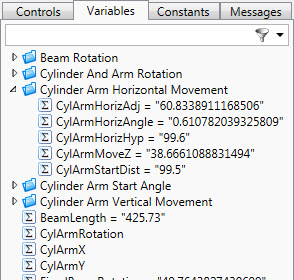

Well, generic rules and functions mean that they can be used for multiple calculations, without being changed. At the root of most of these is the function MyName(). Ever since invertebrates emerged from the primordial ooze, we have been asking for our DriveWorks rules to know who they are. MyName() will return to us (depending upon the rule context) the name of a variable, a control name AND property, or a component path and parameter. So if I want to control a macro button (look, location, function), I can write a rule that knows that button’s name and whether I’m looking for its top or width or tooltip text.

Well, that’s great, but I often don’t want to know something from MyName(), but rather SomeoneElsesName(). Three more functions exist to make this possible. Indirect() is a function brought over from Microsoft Excel that allows us to get the value of another variable. So if I have the value =DWVariableFlowArea, I could also get that using =Indirect(“DWVariableFlowArea”). Well, that’s pretty silly when it’s a static string, but this allows you to build a string because maybe you don’t know if you’re going to need the flow area or the flow volume or the flow speed. Indirect will allow us to build the name of the variable and return its value.

That is where my favorite function (EVER!) comes to light, Substitute(). We can use Substitute() to replace or remove a portion of a string. So I can use Substitute(MyName(), “.Left”, “.Width”) to change “DimensionImage.Left” into “DimensionImage.Width”. Put that inside of Indirect() and I can have the rule for my left location look for my width, critical if you want to center a control on your form.

And the final link in the chain is ExtractNumber(). If a string contains a number or numbers, ExtractNumber() can return just that number for use in another function. A second parameter exists in ExtractNumber() that allows you to tell the rule to retrieve the 2nd or 3rd (or 8th) number in a string, and with positive or negative, which direction to start counting. .

This means that ExtractNumber() can be used to parse a value like “Qty of 9 M8-1.25×45” to pull out any value that you like.

So this is where the intelligent planning comes in. Very often, we will want to write a rule that refers to n-1, that is, the variable or control before me. This could be a running total in a BOM or locating controls in a form.

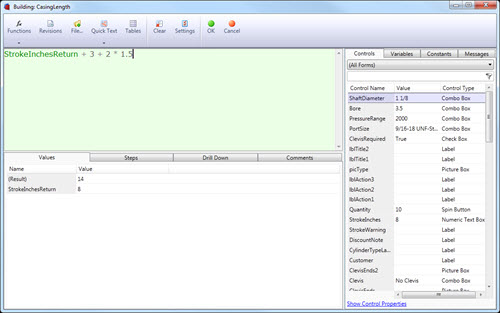

For example, link all of the components listed above and we can use Indirect() to return the value of a control that has the “same name that I do”, except (here comes Substitute()) the number in the name (there’s ExtractNumber()) is one less than mine. Here is one of the most frequently used rules in my forms:

=Indirect(

Substitute(MyName(),

ExtractNumber(MyName(), -1),

ExtractNumber(MyName(), -1) – 1)

)

)

+ Indirect(

Substitute(

Substitute(MyName(),

ExtractNumber(MyName(), -1),

ExtractNumber(MyName(), -1) – 1)

),

“.Top”,

“.Height”)

)

+ DWVariableControlVerticalGap

This rule locates the top of a control based on the location and height of the control before it. The rule simply adds the top location of the previous control plus the height of the previous control plus a gap value.

Here’s how it works. We use indirect() twice, to get the top location value, then the height value. The value is MyName(), which let’s say is Button9, but we replace the number at the end of my name

[ExtractNumber(MyName(), -1)]

with the number at the end of my name minus 1

[ExtractNumber(MyName(), -1) – 1]

So that lets me (Button9.Top) get the top location value of the button before me (Button8.Top). To that, I’m going to add the height of the button above me. The method is the same, but this time, after we get the string “Button8.Top” the way that we did above, we’re going to use another substitute() to replace “.Top” with “.Height”. So now we have the top of the button before me plus the height of the button before me, which is the bottom of the button before me, and add in a little bit of a gap, and presto-magic, you now have this button tied to the button above.

This gets even more helpful when you realize that doing a COPY/PASTE of a control or variable that ends with a number, will create a new control or variable with the number at the end incremented. And since our rule is completely generic, it will automatically work with the new control. Do you need a field of 60 macro buttons? Just create one with all the right rules, and paste away.

(Note: If you copy/paste controls and they do not update properly, save and reload your project. This will often reset the values and make everything right with the world.)

The rules are longer this way. The rules take a bit of thought until you get used to them. But you only need to write them once and you are done. All our implementations use a group table with settings from fonts to paths to colors and database information. Reusing a single rule allows us to retrieve any setting by just having the name of the setting match the name of the variable. So, get started with utilizing generic rules to make your implementation more flexible and more scalable. And extra credit if you combine it with a calculation table. But that’s another discussion altogether.

For more information about Razorleaf, visit https://www.razorleaf.com/