What Happened at Virtual DriveWorks World 2021

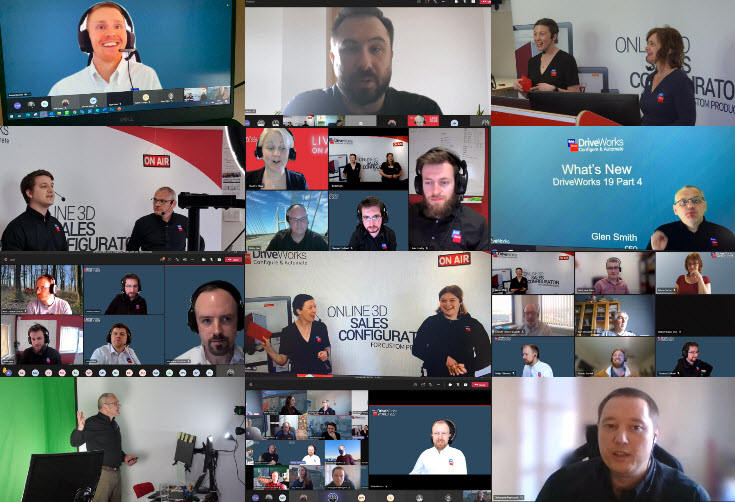

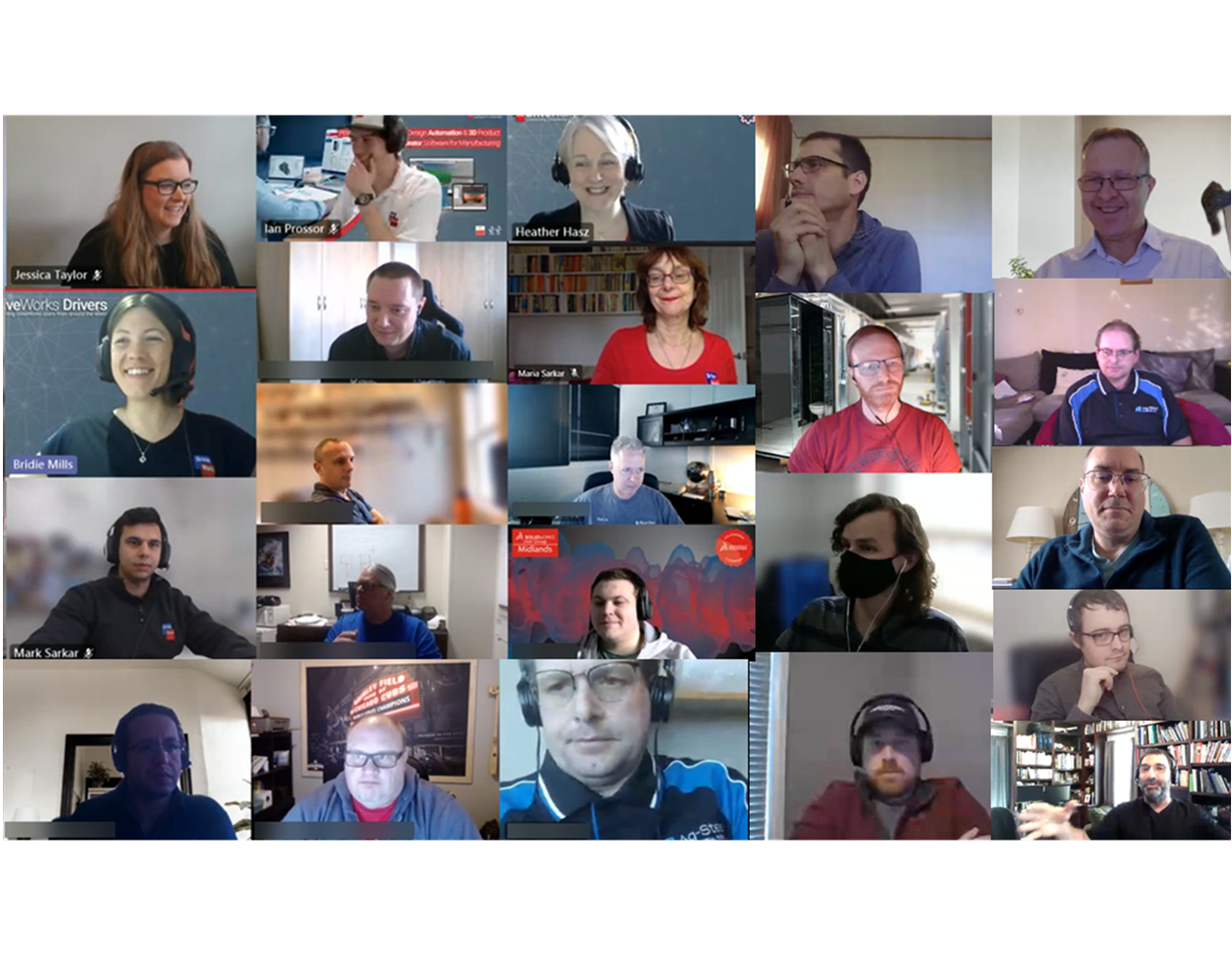

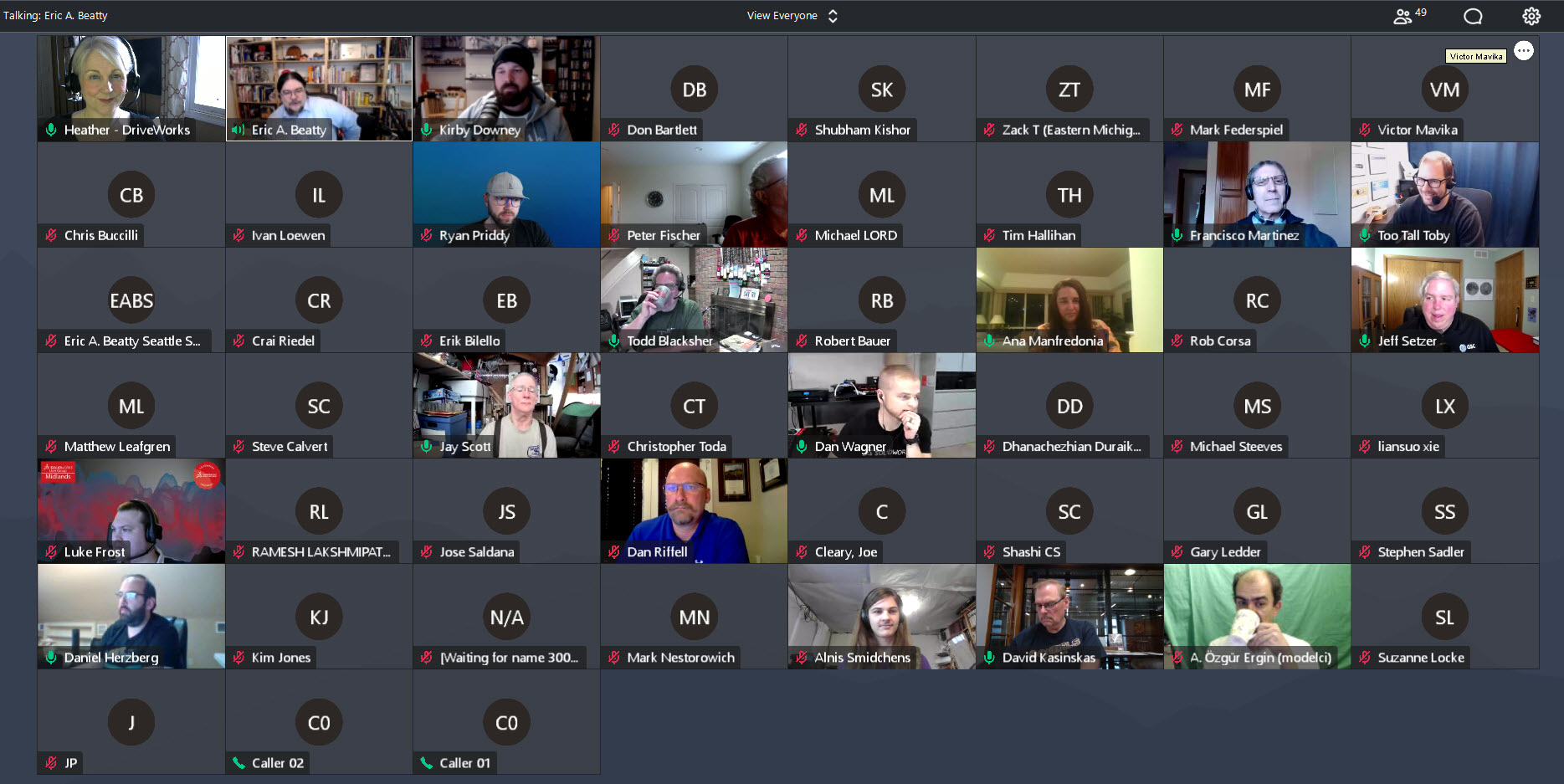

This week we were joined by over 450 DriveWorks customers, resellers and partners from 39 different countries to talk and learn about all things DriveWorks.

Whilst once again the current global situation stopped us from hosting a face-to-face event, we wanted to build on what we delivered for Digital DriveWorks World 2020 and create an even more ‘DriveWorks’ style virtual event.

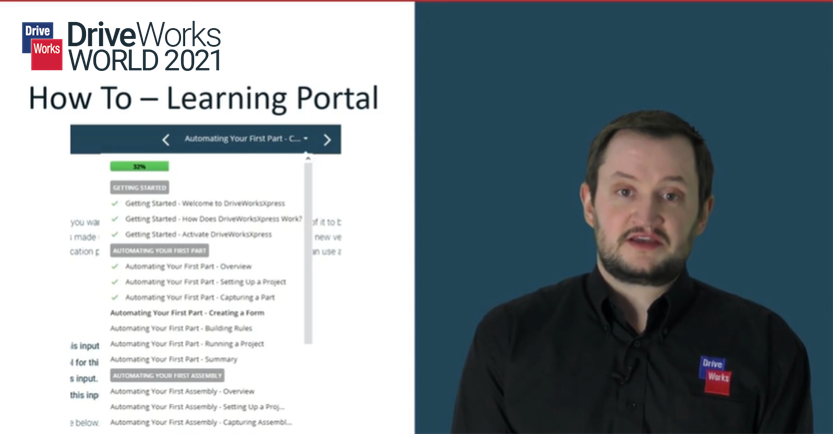

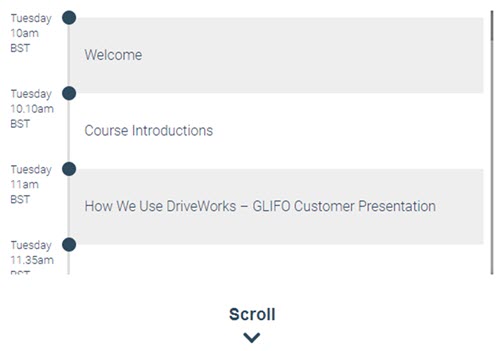

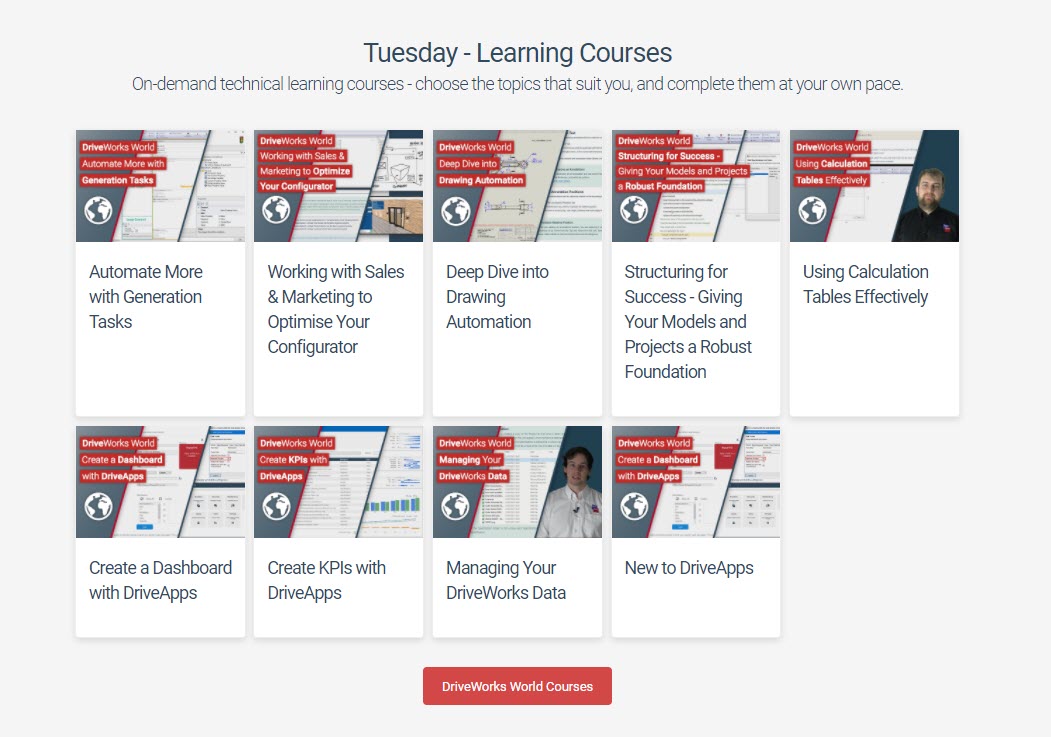

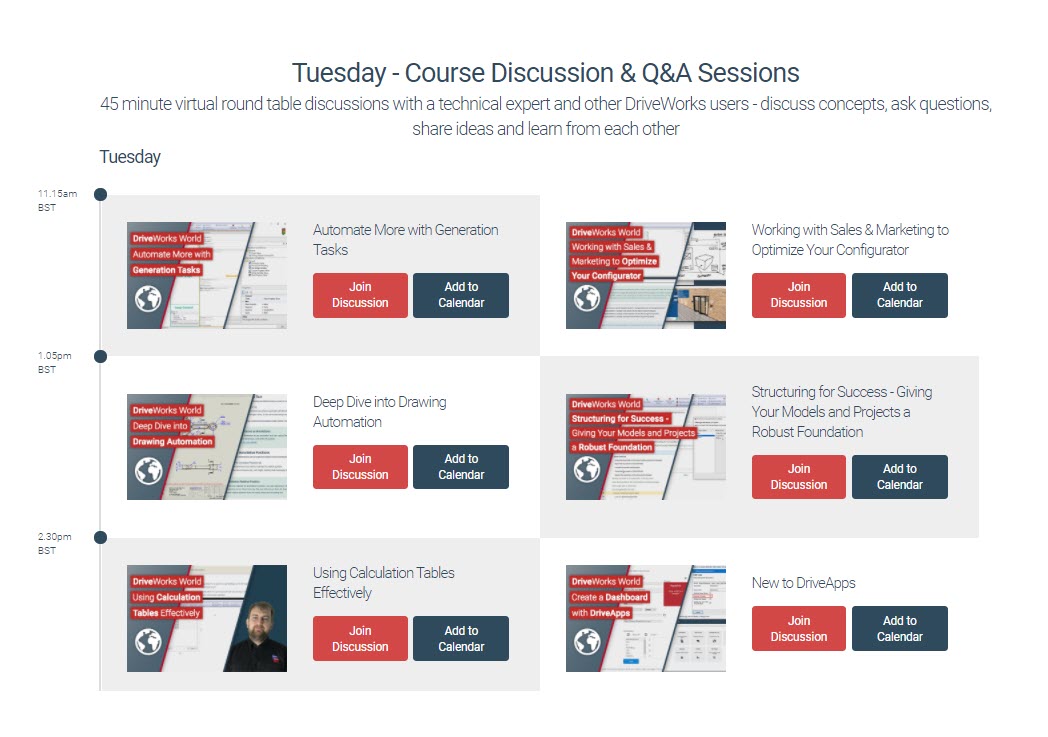

The technical sessions we run at DriveWorks World are extremely valuable and are part of our commitment to Helping You to Help Yourself. We wanted to make sure we could still deliver all the engaging content, technical training, and DriveWorks fun that we know our delegates love.

With more time to prepare this year, we made sure that we could make this the best virtual version of DriveWorks World possible!

Using technology, we delivered 2 full days of learning, networking and sharing ideas – all virtually.