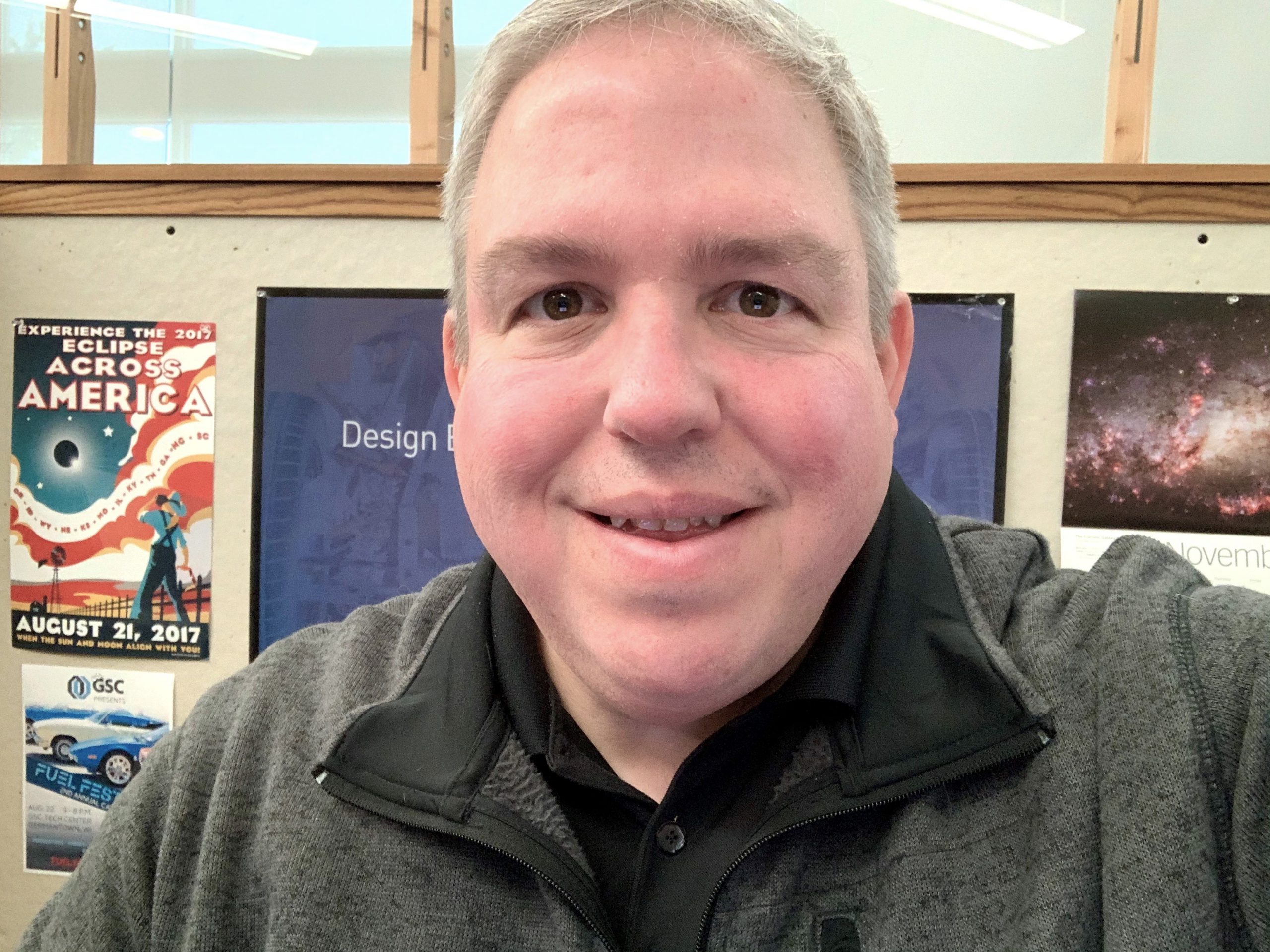

Jeff, having worked at GSC for so long, please share with us some of the roles you’ve had.

Sure – early on in my career with GSC I worked in tech support. As we were a small company, we all held multiples roles and I was also the marketing person for a while. We created some promotional pamphlets about SOLIDWORKS to send out to customers. I also helped with logo creation, designing t-shirts, and miscellaneous marketing tasks. For a bit, I even worked as the internal IT person. We just did what we needed to do as a small company.

As our team grew, I took on the role of Technical Services Manager which I did for a long time. That was probably the longest role I’ve had with GSC. Over time, others started taking on other roles and I’ve now grown into the position of Technology Evangelist.

Jeff’s twin brother, John Setzer, started at GSC about 3 years after John, he had been an English teacher and developed an interest in CAD and technology. He now works as the Training Manager at GSC.

What does a Technology Evangelist do?

To be honest, I gave myself this title a few years back and it’s really defined what I like to do. In the role of Technology Evangelist, I take a lot of time to learn software products and then advise people on how new technology can help them. I’m not training them in how to use the software, but more providing counsel and advocacy in what they should be using.

Honestly, it really is more of a technology and marketing role combined. I spend a lot of time with both teams during my work week but find I’m working more with marketing. We help create messaging about software and technology for the community to learn about products. Creating content and promotions are really helpful to support things like our Technical Communications Week that we host. While I didn’t participate directly in the event, I worked with marketing to create some of the promotional content – it’s fun to create ways to talk about technology.

I love participating in the software rollout events and look forward to it every year. It’s at the rollout events and other events where I do more talking and ‘evangelizing’ of software.

While it’s my job to learn and stay updated on SOLIDWORKS software (including products such as Electrical PCB, Simulation, etc.) as well as what’s available through the 3DEXPERIENCE Platform, I also keep an eye on competitive software so I can understand what else is being used out there.