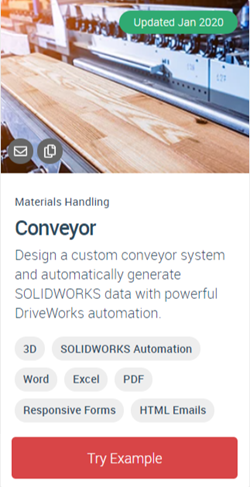

Configuring a Custom Conveyor

The global pandemic has led to fewer face to face meetings. And it’s also making 3D visualization and online configuration, essential commercial tools for manufacturers of custom or customizable products.

Creating custom products and delivering a personalized digital experience can increase profitability for manufacturers who sell to other businesses.

More buyers are also looking for products that meet their exact needs and expect shorter sales cycles and better buying experiences.

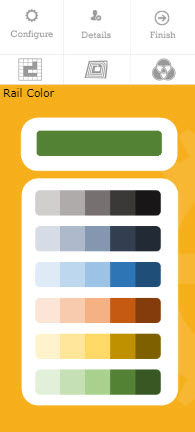

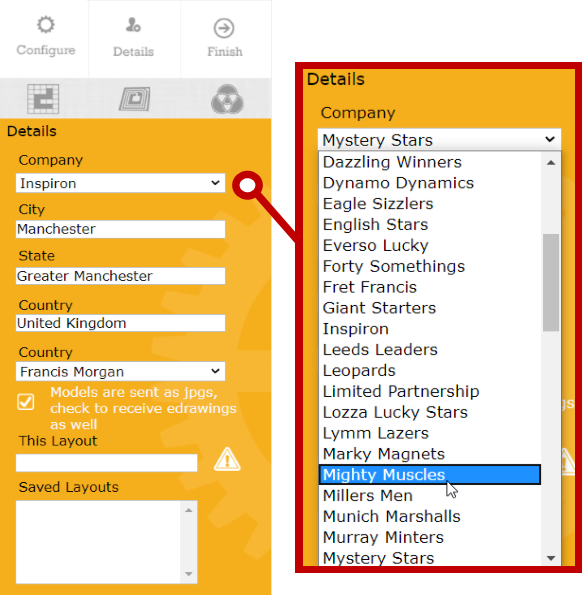

Implementing an interactive online sales configurator enables your customers, distributors, or inside sales teams to configure a custom product, get instant quotes, see accurate delivery dates, and even place their orders, in one simple session.

Online sales and digital manufacturing are key aspects of digital transformation.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action. Anyone can use the online configurators, created using DriveWorks software.

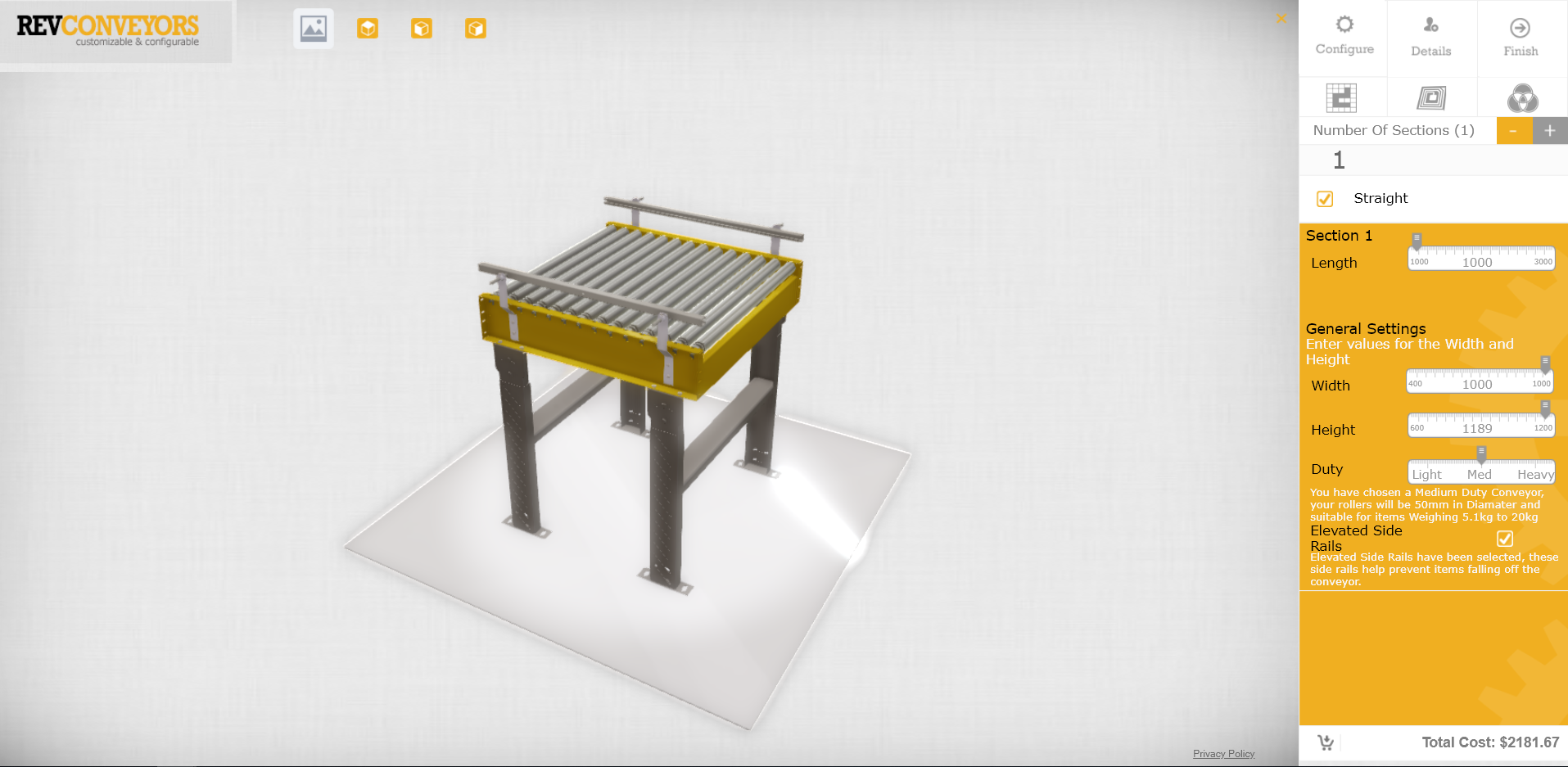

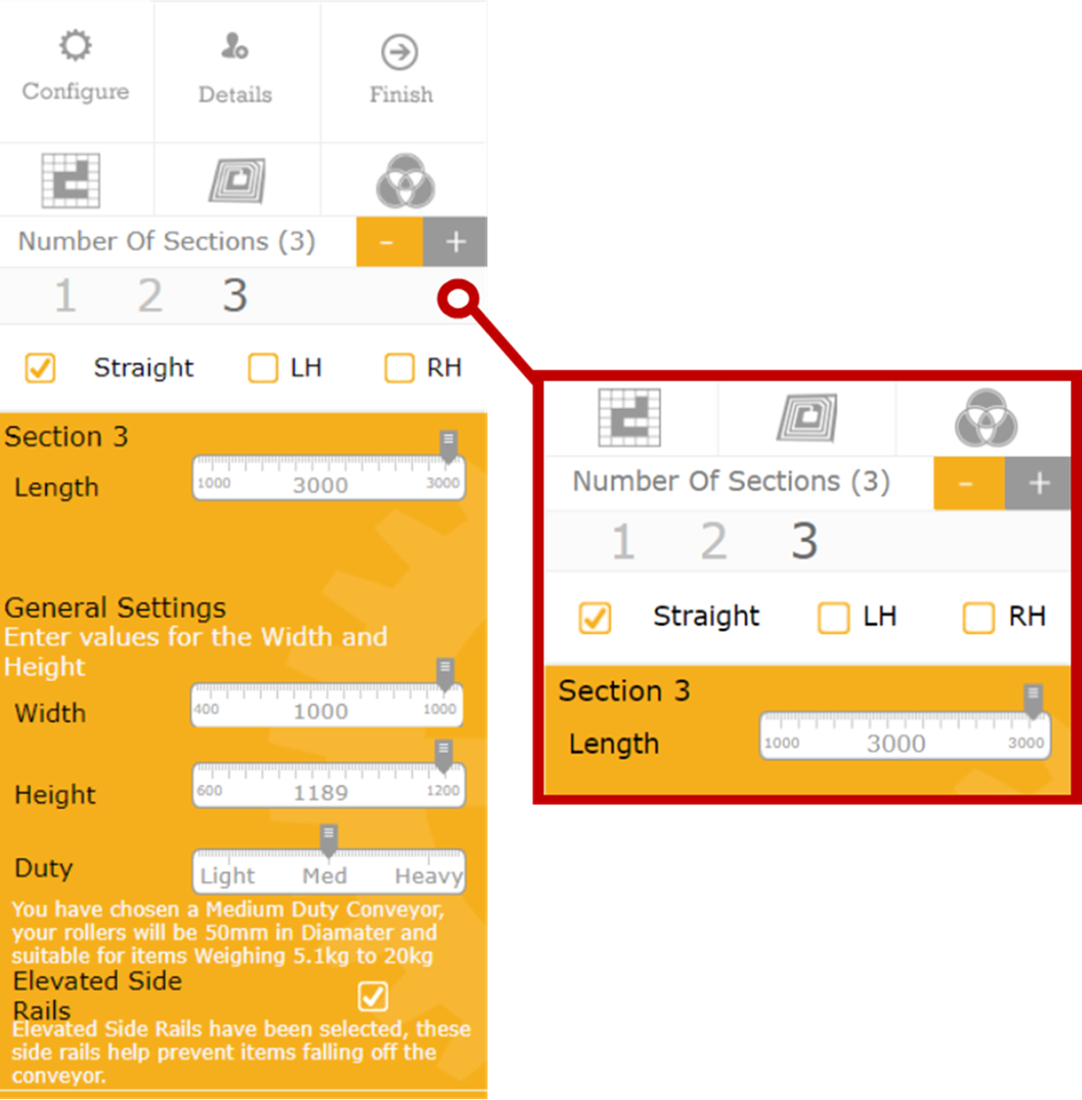

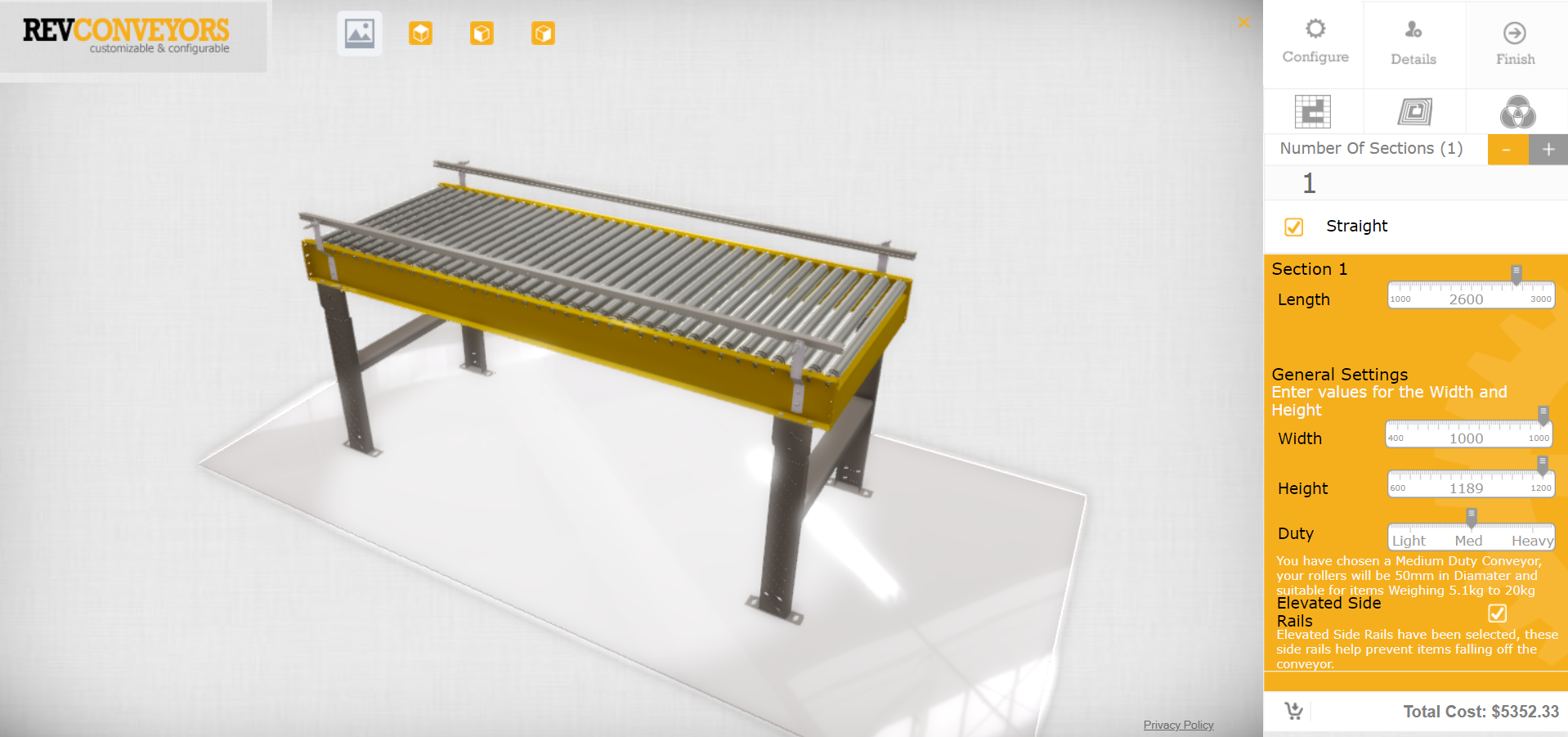

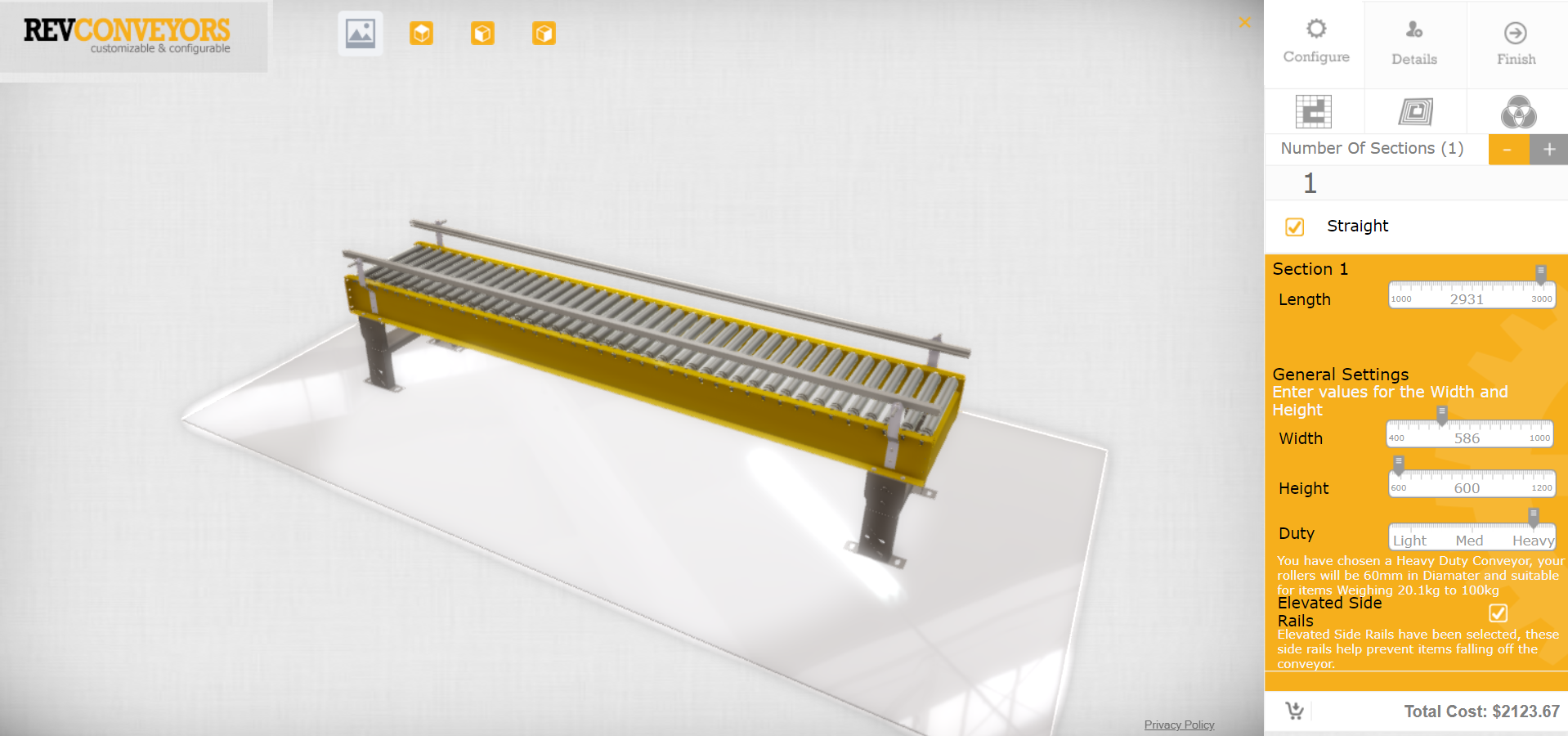

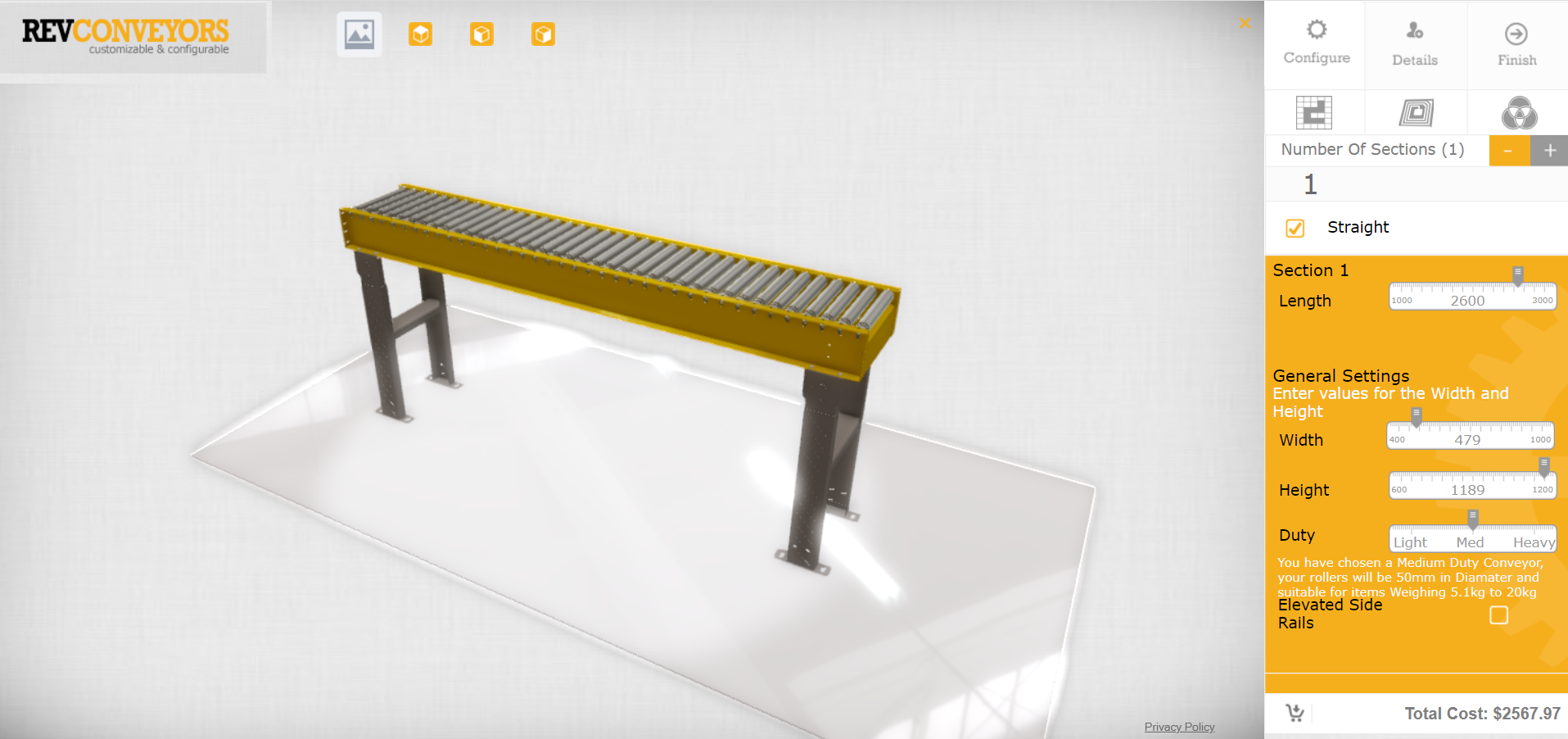

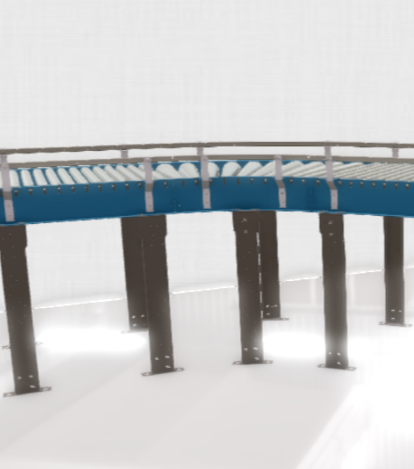

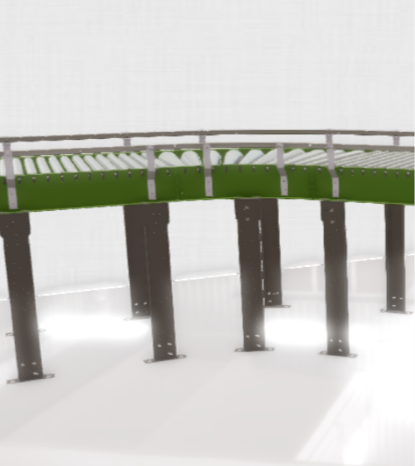

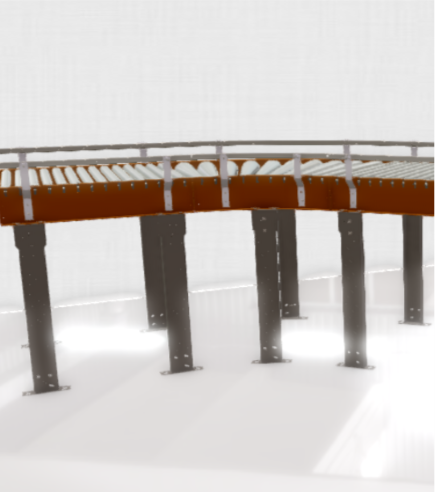

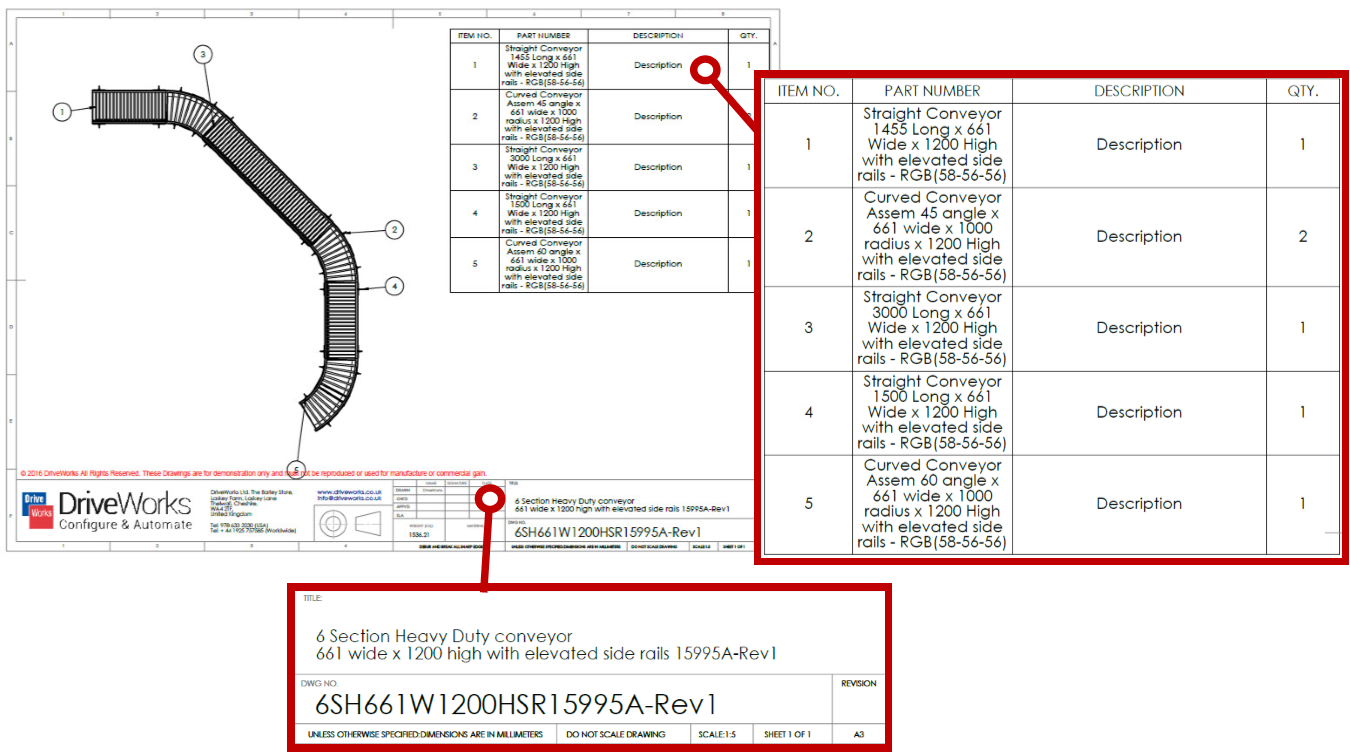

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom conveyor system online.

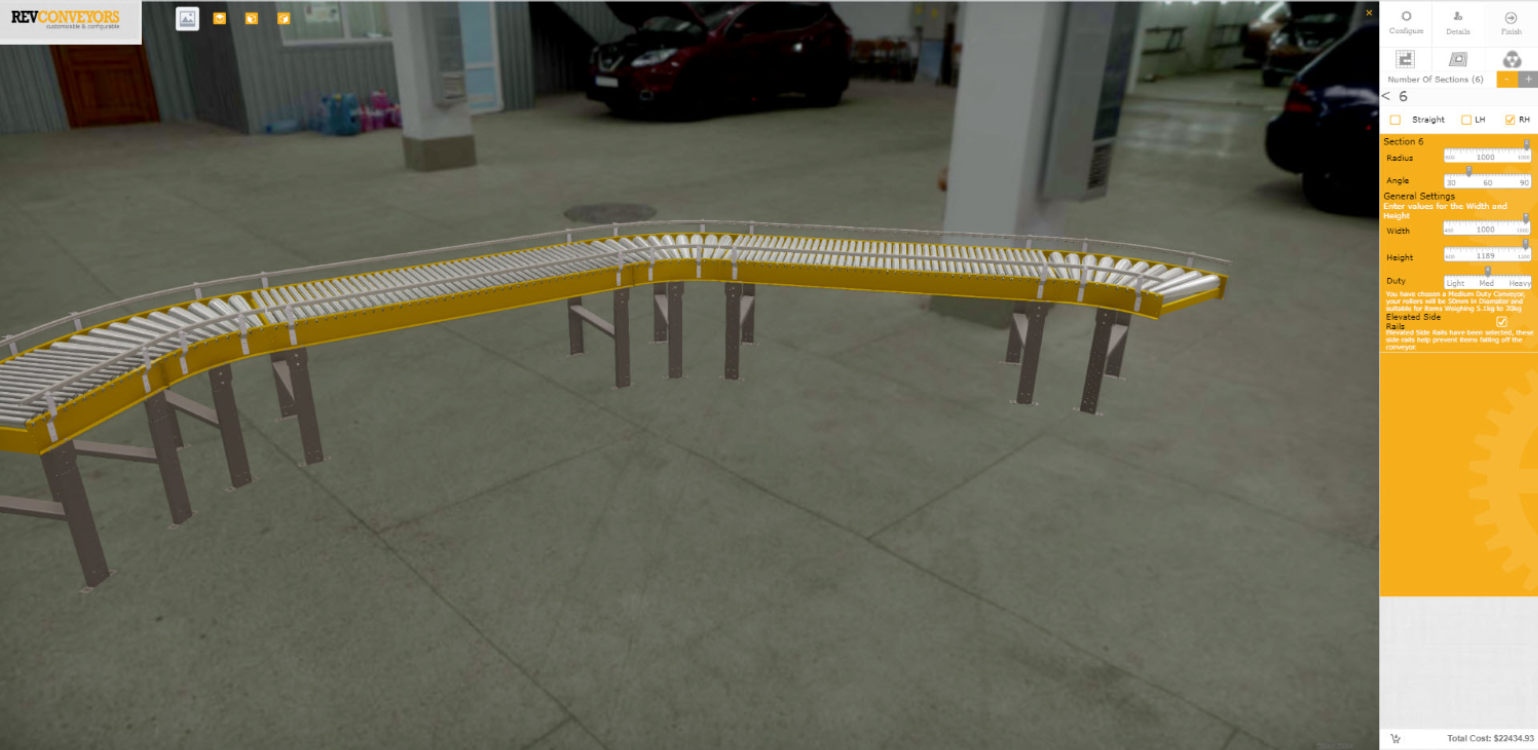

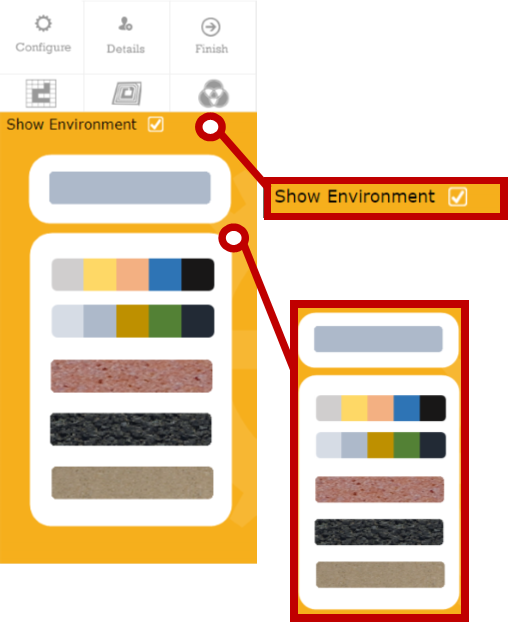

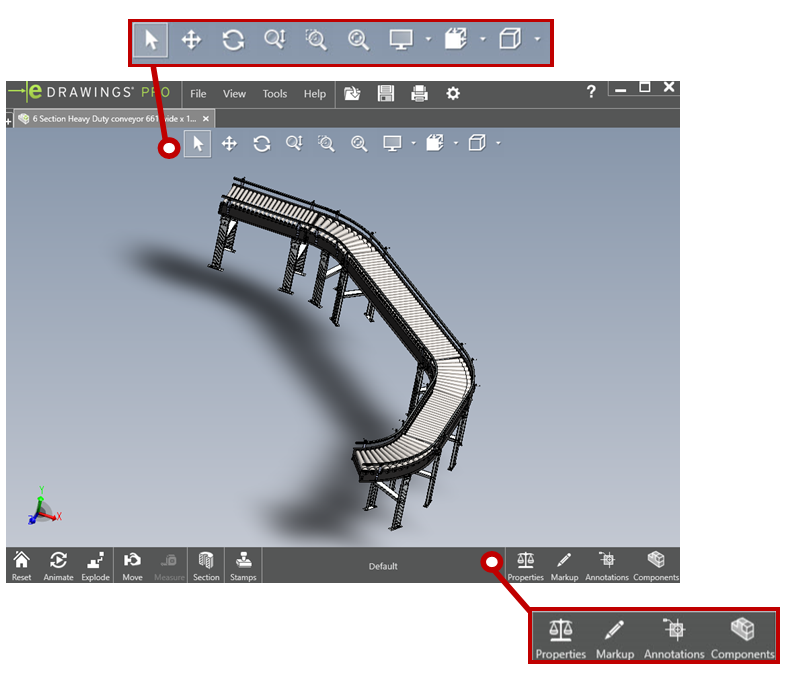

With DriveWorks 18, our team added lots more 3D capability to bring the product to life. The conveyor positioned in a 3D environment has context, just as real-time 3D visual configuration means the effects of the design changes can be viewed almost immediately.

In this example, I’m going to configure a custom conveyor. I’ll choose the number of sections, alter dimensions and angles, and all based on engineering rules and know-how.