DriveWorks configurator software is the ultimate choice in 3D CPQ for SOLIDWORKS.

The ability to configure, price and quote easily has become essential for manufacturing companies of all sizes, in all industries. We’ve all seen, and probably used, some kind of sales configurator. They’re now widely used by many recognized brands as a way of cost-effectively offering configurable products.

Configurable products are becoming the norm and many companies are seeking a configure, price and quote (CPQ) solution that can help them to meet the increasing demand for custom products and gain a competitive edge.

DriveWorks is a SOLIDWORKS Gold Partner Product and only works with SOLIDWORKS.

Since 2001, DriveWorks has worked alongside SOLIDWORKS to help companies improve their processes and win more orders.

How Your Customers Use DriveWorks as a CPQ Solution

How Your Distributors Use DriveWorks as a CPQ Solution

How Your Sales Team Use DriveWorks as a CPQ Solution

How You Set Up

DriveWorks as a CPQ Solution

DriveWorks configurator software enables businesses to set up a configurable 3D CPQ solution that engineering and sales teams can use. DriveWorks allows manufacturing companies to gain all the benefits of digital selling.

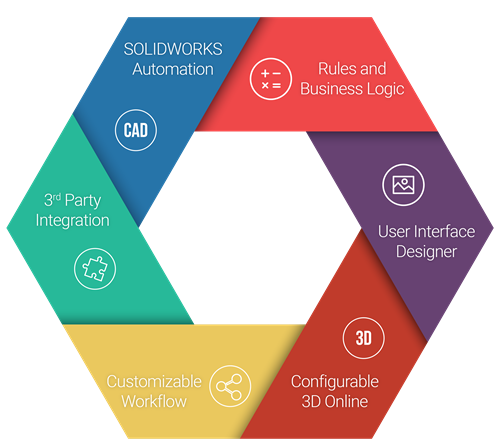

CPQ solutions are built on rules, workflow, user interface and integration. These are the core technologies that have underpinned DriveWorks since the software was first introduced to the SOLIDWORKS market in 2001.

Over the years by looking at market trends, conducting research amongst manufacturing companies and asking for customer feedback, new features have been added and many enhancements made. With our goal of ease of use, we’ve created a specific CPQ template, built on DriveWorks functionality, to make it easy for manufacturing companies to reap the benefits of guided selling and CPQ quickly.

The DriveWorks CPQ Template provides a configurable dashboard that allows you to select which products can be configured, using your existing DriveWorks product configurators, what pricing to apply and what data to pass to and from any other company systems such as ERP and CRM.

Your DriveWorks and CPQ administrator can manage access and permissions to the CPQ front end and add product configurators at any time. That way you can customize the solution for inside sales, dealers, distributors and even customers. The CPQ administrator can apply real-time pricing updates to ensure accurate quotes are generated and that they reflect your businesses’ strategic and commercial goals. The CPQ dashboard can also be customized so the administrator can have specific views such as quoted items, pending orders and so on.

The four short videos above explain and demonstrate DriveWorks CPQ from the point of view of a customer, distributor, sales representative and CPQ administrator.

Let your customers see their custom products in impressive 3D and view the effects of their design changes immediately.

Automatically send eye catching branded documents that are personalised to each customer and order.

Get started really quickly by customising our templates to suit your needs with our intuitive Form Designer.

An easy to use workflow means seamless links between teams & company systems such as CRM, ERP and SOLIDWORKS.

Reduce repetitive tasks by automating customer responses and repetitive engineering tasks.

Additional modules can be added as and when you need them to create a product configurator that suits your needs.

Try out one of the many CPQ configurator examples on DriveWorksLive.com.

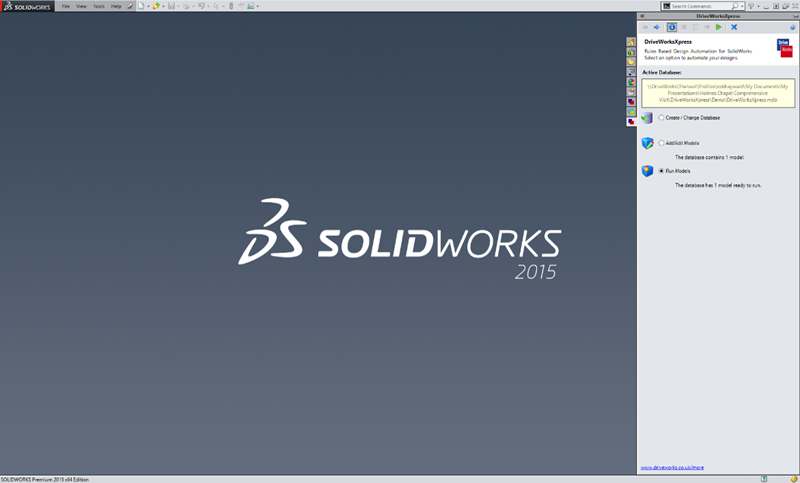

DriveWorksXpress is the time-saving Design Automation tool, free inside every licence of SOLIDWORKS.

It’s ideal for configuring designs that are the Same but Different.

Configuring and automating your designs with DriveWorksXpress is easy:

As DriveWorksXpress is based on your rules, you’ll save time, reduce repetitive tasks and minimize errors and costly mistakes.

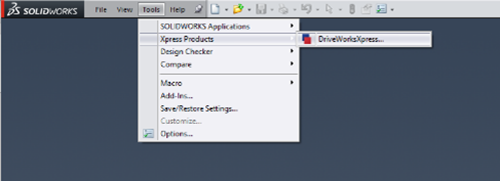

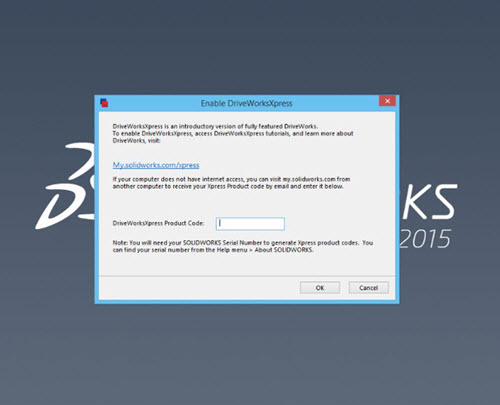

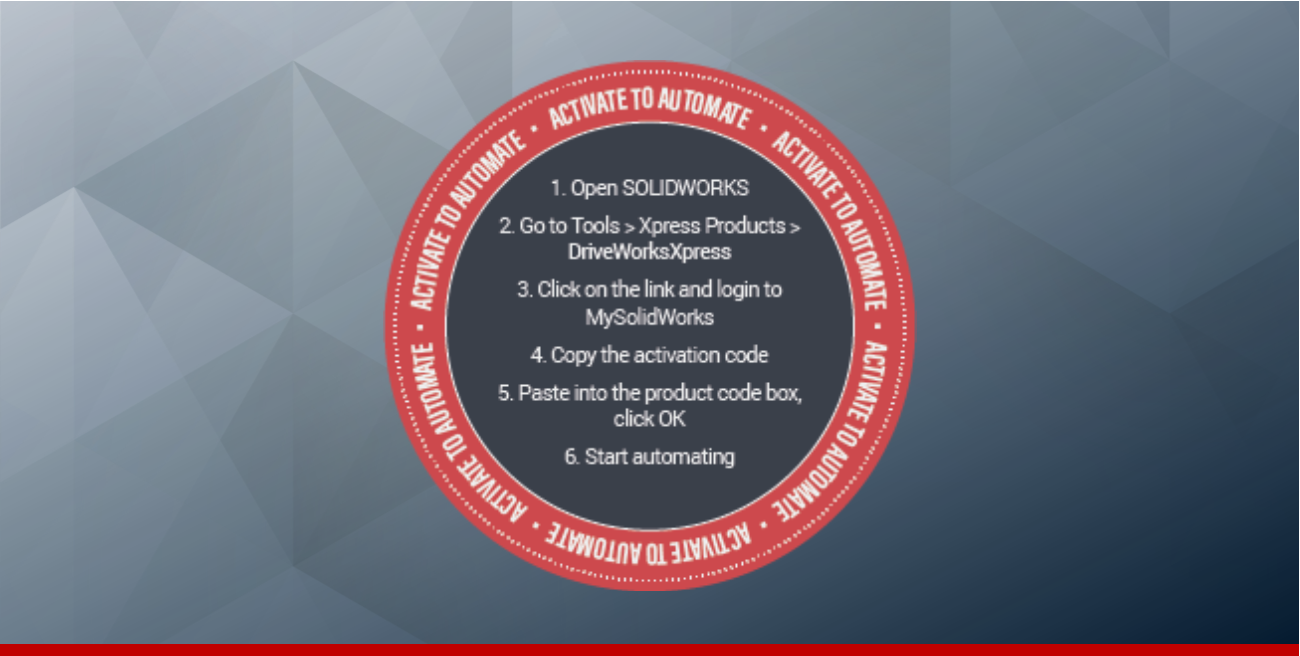

To activate DriveWorksXpress inside SOLIDWORKS and start automating your designs, follow these quick and easy steps:

Open SOLIDWORKS

Go to Tools, Xpress Products, DriveWorksXpress

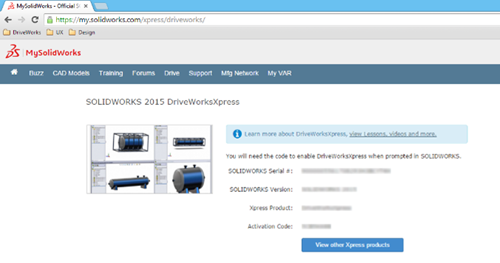

Click on the link for My.SolidWorks.com/xpress to get your free activation code for DriveWorksXpress.

Copy the DriveWorksXpress activation code.

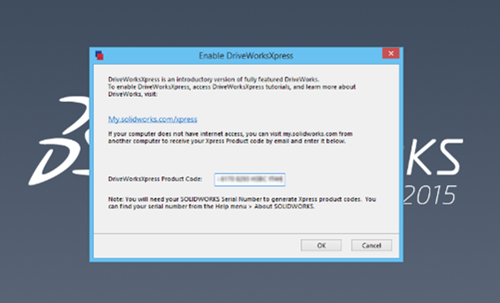

Go back to SOLIDWORKS, paste the activation code in to the product code box and press OK.

Start automating!

Learn more about DriveWorksXpress with these free online resources:

We’re pleased to welcome Mike to the DriveWorks team as a Technical Specialist.

Mike has known our team and our product for many years, using DriveWorks software throughout his career.

Mike brings with him extensive knowledge of industry, design, manufacturing and SOLIDWORKS.

Look out for some of the great content Mike will be creating, as part of our aim to help you to help yourself.

Here’s a bit about Mike and his career…

I have worked as a designer in many different industries for over 25 years. I came into design via the artistic route, completing an Art foundation course, before studying 3D Design for TV and Theatre. Model making was great fun, often using foam board and spaghetti with glue all over my hands.

Since then I have worked in several different industries:

– Furniture and Interior Design

– Construction

– Machinery

– Transportation

I have used SOLIDWORKS since 2001. I created my first DriveWorks project in 2002 when I first met Glen, Maria and Ian from the DriveWorks team.

I used DriveWorks for specifying office furniture. It was quick and accurate, bringing down lead times and reducing rework in manufacture.

Using DriveWorks made a significant difference to new starters. They were productive after a week because a rules-based system requires minimal checking.

In my next role, I added CAMworks to SOLIDWORKS and DriveWorks to aid design and manufacturing automation. Out of a huge factory in Manchester, we designed offsite buildings such as Whiston Hospital in Liverpool.

A major highlight was SOLIDWORKS filming our design process to show at SOLIDWORKS World 2008.

My career path continued with designing bespoke machinery for the Materials Handling industry. I then went on to design lorry chassis and bodies using SOLIDWORKS.

For the last 4 years, I have been working as a Technical Consultant for SOLIDWORKS and DriveWorks reseller, NT CADCAM. There I was training, consulting and demoing the SOLIDWORKS product portfolio, including DriveWorks.

Working for a SOLIDWORKS reseller means plenty of yearly exams and assessments. I was very pleased to receive my SOLIDWORKS Elite Applications Engineer certification, and crystal, at SOLIDWORKS World 2017.

I am pleased to now be contributing to the future and growth of DriveWorks. I look forward to communicating ideas and creating great content.

I’m excited to meet many other DriveWorks users at DriveWorks World this year and be on the other side of the event!

I am passionate about creativity, whether that be designing a brochure, a building, a donut dusting machine or a vehicle chassis.

Fun fact, I have designed office furniture, shops and lorry trailers for Morrisons, a popular supermarket in the UK.

The core DriveWorks functionality is continuously extended and improved based on customer feedback and enhancement requests. A new version is released yearly with a further 2 service packs for each release.

DriveWorks software is robust, reliable and trusted. Before any major release or service pack, the latest version goes through the following processes:

Agile development methodologies ensure we can respond to changing market demands quickly, whilst tracking and managing every aspect of the development cycle to guarantee quality.

Code reviews undertaken by our Senior Developers ensure that every line of code meets our strict quality standards before it is included in our software.

One of our core aims is ease-of-use. We conduct usability research and specific feature testing to try to make sure DriveWorks is as obvious and easy to use as possible.

We use DriveWorks software running on multiple machines to us measure quality and performance. Typically this generates over 1TB of SOLIDWORKS files and data.

In addition to our automated QA process, the DriveWorks Technical Team conduct physical tests throughout alpha, beta and pre-release phases to ensure stability and reliability.

The DriveWorks Help Files and Online Documentation are updated to reflect the new features and functionality added to each new release. Anyone can learn about the updates and how to use them.

We want to give our users peace of mind by making sure that the software robust and reliable.

Make sure you’re on the latest version, so you can take advantage of the latest tried and tested functionality and performance enhancements.

Whilst at SOLIDWORKS World 2018, be sure to visit the Partner Pavilion where you can meet SOLIDWORKS Partners, preview new technology and view innovative products.

We’ll see you where the action is, in the SOLIDWORKS Partner Pavilion.

Don’t forget to also head over to booth #133 to see the new ‘Shop Floor’ where SOLIDWORKS are recreating a typical manufacturing environment for the production and inspection of an automotive gear shift arm.

Refreshment breaks will be held in the Partner Pavilion so you’ll have plenty of time to explore!

Don’t miss a minute of the action! Make sure you know about the new timings and new schedule for 2018.

1pm-1.30pm:

Reseller Exclusive Preview

1.30pm-3.30pm:

Welcome Reception

2.30pm-2.45pm:

Certified Partner Theatre Presentation

10am-4.30pm:

Partner Pavilion Open

6pm-8pm:

Reception

10am-4.30pm:

Partner Pavilion Open

10am-2.30pm:

Partner Pavilion Open

See you in LA!

SOLIDWORKS World 2018 is just around the corner and the DriveWorks team can’t wait to head to the airport and make their way to Los Angeles! We’re looking forward to welcoming you to our booth #511 in the Partner Pavilion and previewing our next release – DriveWorks 16.

Over the course of the event, you’ll choose from over 200 breakout sessions which cover a wide range of subjects. We’re hosting a number of Design Automation and CPQ presentations and we hope you can join us to learn more.

Our first presentation is hosted by John Bannon, our Technical Territory Manager, and it kicks off on Sunday 4th February in the Partner Pavilion.

When?

Sunday 4th February 2018.

2:30pm – 2:45pm.

Where?

The SOLIDWORKS World 2018 Partner Pavilion.

Find out what’s involved in automating your repetitive design tasks using SOLIDWORKS Certified Gold Partner product, DriveWorks, at SOLIDWORKS World 2018.

John Bannon, DriveWorks’ Technical Territory Manager, will introduce the technology and show how you can automatically create SOLIDWORKS part, assembly and drawing files to save time and respond to customer enquiries more quickly.

John will take a look under the hood, showing how to build rules in DriveWorks, how to create custom forms and how to generate production data quickly and accurately. DriveWorks is ideal for manufacturing companies who design and sell products that can be described as “the same but different” for each order.

DriveWorks World 2018 is just around the corner, register now to secure your place!

Register before the 16th of February 2018 and you’ll save £200 per person with the early bird rate.

This is your chance to learn, network & share ideas with DriveWorks experts & enthusiasts. There will be something of interest and value to you, whether you are new to DriveWorks, or are an advanced user of the software.

Join us to be inspired and advance your knowledge.

This year’s agenda gives you more flexibility to tailor your DriveWorks World experience and learn what’s relevant to you and your DriveWorks project.

This year DriveWorks World will kick off with the main event on Monday, followed by our annual dinner.

On Tuesday and Wednesday, you can then choose either DriveWorks Training and Certification or select from short breakout sessions, covering specific topics. The breakout sessions are divided by topic and skill level so you can learn what you want to, and in as much detail as you need.

The Manchetser Digital Skills Festival is an annual, four-day event that includes a skills conference, the largest digital careers fair in the UK and opportunities for school children to learn digital skills in a practical setting.

Manchester has the ambition to become a leading digital city and in order to achieve this, we need a highly skilled digital workforce that is big enough to serve the needs of an ever-growing industry. We need a pipeline of talent that will leave school, college and university with industry standard, work ready, digital skillsets.

The annual Manchester Digital Skills Festival highlights and addresses the issues facing the sector as well as addressing them on a practical level by hosting the UK’s largest digital recruitment fair, offering tours of local digital businesses and opportunities for local school children to gain some hands on, practical experience.

The Skills Festival is a great chance to showcase the amazing digital businesses we have in the North West and show students that there are wonderful digital career opportunities on their doorstep!

The Digital Skills Conference, an afternoon event on the 13th, will feature talks by various industry leaders, including a futurist and a first look at the results of Manchester Digital’s annual Skills Audit report. There will also be workshops about salary, rewards, inclusivity and diversity. View the full agenda here.

The Talent Day is a must-visit for job seekers. More than 50 digital, creative and tech companies will be available for conversations about your future career in the industry. Seminars, workshops and panel discussions will give you an insight into various placement programmes and graduate initiatives across the region. Job seekers and attendees can book a free ticket here,

Jake and Bridie from the DriveWorks team will be attending. If you’ll be there, make sure you say hello and ask them about careers at DriveWorks!

These experience days are a fantastic chance for students to get practical skills in coding, website building, hacking and more.

The Digital Futures: Computing, Curriculum and Careers Event is aimed specifically at teachers and careers advisers at schools and colleges in Greater Manchester. The half-day event will feature inspirational speakers as well as very practical workshops in interactive digital innovation, ed tech and careers.

For more information or to book your ticket, visit: https://www.manchesterdigital.com/events/digital-skills-festival-2018

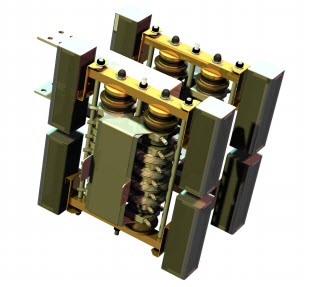

RJ Watson Inc. is based in Alden, NY and focuses on developing structural engineering solutions for the heavy construction industry world-wide. The company delivers a diverse and custom range of products and services including high load multi-rotational bearings, seismic isolation devices, expansion joint systems, noise mitigation materials, and FRP strengthening products for highway and bridge applications.

Due to their Civil/Structural Engineering roots, the company had traditionally used 2D design applications for their engineering drawings. General 2D drawings are the requirement and have been the industry standard for decades. In 2013, RJ Watson recognized a potential opportunity to improve their process by leveraging the ability of parametric 3D modeling. Even though each of their bearing designs is custom and built based on application requirements, there is still consistency in the components. Each custom build is essentially a different configuration of something that has already been designed.

While reviewing RJ Watson’s process, CADimensions recognized the amount of effort spent toward fulfilling project proposal requirements. In order to be considered for a project, complete 2D product and general purpose drawings along with product specification data is required. Significant engineering resources were needed to fulfill these requirements even though they may not win the business to recoup that investment. This bottleneck hindered their ability to bid on all possible projects and increase the risk of missing deadlines on projects that they were pursuing.

RJ Watson invested in SOLIDWORKS to create their bridge bearing and product designs in 3D, and were able to automate the configuration of their assembly models and drawings based on specific bridge requirements with the use of DriveWorks. By implementing these tools, RJ Watson was able to reduce errors associated with product assembly and reduce the amount of time needed for fulfilling project proposal requirements by 50%.

By using DriveWorks to automate the process of creating drawings and elimating the need to adjust based on all custom builds, they were able to increase the number of new project bids, which they expect will yield more business for 2018. The overall process improvement will now support the future growth and goals for the company.