Our Tech Team Thursday webinar series gives all DriveWorks Pro Customers with an Active Subscription Support Contract, and Reseller AEs, the chance to learn directly from members of the DriveWorks Technical Team. In these exclusive 30 minute webinars, the DriveWorks Technical Team share their knowledge and expertise, covering a wide range of topics, taking a closer look at specific aspects of DriveWorks Pro.

On Thursday 2nd November, our Product Manager, Matt, will be presenting a Tech Team Thursday webinar about the new DriveWorks CPQ Template.

Our CPQ template, built on DriveWorks functionality, makes it easy for manufacturing companies to reap the benefits of guided selling and CPQ, quickly.

It provides a customizable dashboard to select which products can be configured, using existing DriveWorks product configurators, what pricing to apply and what data to pass to and from any other company systems such as ERP and CRM.

The template also makes it easy to manage permissions, real-time pricing updates and views to create a customized solution for inside sales, dealers, distributors and even customers.

DriveWorks Pro customers already have access to all of this functionality within DriveWorks. The CPQ template we’ve created simply makes it even easier to quickly set up the functionality as a customisable CPQ solution.

This webinar is specifically for DriveWorks customers with Active Subscription Support Contract, and our Reseller AEs to learn about the template and how to use it. If you’re not a DriveWorks Pro customer but would like to learn more about the CPQ functionality in DriveWorks, find out more here. Or, have a go with one of our CPQ configurator examples on DriveWorksLive.com.

Contact us if you have any questions about CPQ with DriveWorks.

The ability to configure, price and quote easily has become essential for manufacturing companies of all sizes, in all industries. We’ve all seen, and probably used, some kind of sales configurator. They’re now widely used by many recognized brands as a way of cost-effectively offering configurable products.

Configurable products are becoming the norm and many companies are seeking a configure, price and quote (CPQ) solution that can help them to meet the increasing demand for custom products and gain a competitive edge.

DriveWorks configurator software enables businesses to set up a configurable 3D CPQ solution that engineering and sales teams can use. DriveWorks allows manufacturing companies to gain all the benefits of digital selling.

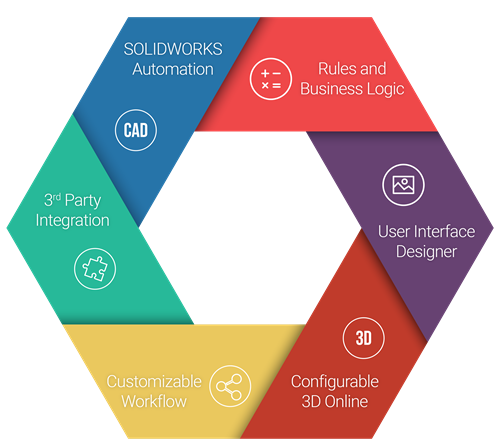

CPQ solutions are built on rules, workflow, user interface and integration. These are the core technologies that have underpinned DriveWorks since the software was first introduced to the SOLIDWORKS market in 2001.

Over the years by looking at market trends, conducting research amongst manufacturing companies and asking for customer feedback, new features have been added and many enhancements made. With our goal of ease of use, we’ve created a specific CPQ template, built on DriveWorks functionality, to make it easy for manufacturing companies to reap the benefits of guided selling and CPQ quickly.

The DriveWorks CPQ Template provides a configurable dashboard that allows you to select which products can be configured, using your existing DriveWorks product configurators, what pricing to apply and what data to pass to and from any other company systems such as ERP and CRM.

Your DriveWorks and CPQ administrator can manage access and permissions to the CPQ front end and add product configurators at any time. That way you can customize the solution for inside sales, dealers, distributors and even customers. The CPQ administrator can apply real-time pricing updates to ensure accurate quotes are generated and that they reflect your businesses’ strategic and commercial goals. The CPQ dashboard can also be customized so the administrator can have specific views such as quoted items, pending orders and so on.

The four short videos below explain and demonstrate DriveWorks CPQ from the point of view of a customer, distributor, sales representative and CPQ administrator.

How Your Customers Interact with DriveWorks as a CPQ Solution

How Your Distributors Interact with DriveWorks as a CPQ Solution

How Your Sales Teams Interact with DriveWorks as a CPQ Solution

How You Administer Your DriveWorks CPQ Solution

PS DOORS was established in 1974 and they’re located in Grand Forks, North Dakota.

They’re an industry leading manufacturer of safety and fall protection products (PS Safety Access™), flood protection products (PS Flood Barriers™) and industrial doors (PS Access Solutions™).

The company manufactures custom products to cover openings and transitions for a variety of reasons and in a number of different ways. They serve a wide range of industries including: military, oil & gas, agricultural, food processing and manufacturing.

DriveWorks is a perfect fit for PS DOORS as they have a range of standard products that can also be customized—they’re the ‘same but different’.

When PS DOORS first acquired SOLIDWORKS, they would ‘pack and go’ previous jobs and modify them to fit the criteria of a new order. Their entire process has changed over the past 10 years, particularly since they incorporated DriveWorks, which is now used internally by the company’s engineering and sales teams.

Since acquiring DriveWorks, their throughput has increased by 300% while their design team has only increased by 25%. This is due to DriveWorks enabling them to do more with less. Products that have been integrated with DriveWorks have seen an average of 75% reduction in design time.

Using DriveWorks enables PS DOORS to produce custom drawings in a short amount of time while maintaining quality standards throughout the design and manufacturing process. Additionally, they are starting to incorporate more office tasks into DriveWorks, such as creating quotes and data management.

For PS DOORS, the most important thing about DriveWorks is using the software to provide highly customized products in less time and to exceed expectations.

“If we can produce a high quality, highly customized product, that costs less and takes less time, then we hope to exceed our own expectations and those of our customers.”

Seth Dallman—DriveWorks Application Administrator at PS DOORS.

Last week, Heather from the DriveWorks team was on the road completing a SWUGN tour of the South and Southwest USA. She’s back in the office after a busy week and we caught up with her to find out more about her tour.

“On Monday morning, I boarded the first of many flights as I headed out to Dallas/Fort Worth for the first stop on my trip. That evening, I had the pleasure of presenting at the Fort Worth Texas SOLIDWORKS User Group. The meeting was well attended and there was a great mix of both seasoned SOLIDWORKS users and students, which made for a great meeting.

I presented to the group about DriveWorksXpress and everyone was able to see how simple it is to automate their designs in SOLIDWORKS.

After my presentation, Amee Meghani from GoEngineer gave a great presentation. Her “30 Tips and Tricks in 30 minutes” gave users important tools and insight to help with their everyday design work.

Craig Gilbreath was a great host and the Fort Worth SWUG meeting was a great kick-off to my week!”

“Next up was a visit with Christie Buresh and the North Texas SOLIDWORKS User Group. The meeting location was the Dallas Makerspace and it was an awesome venue for a SWUG meeting. The Dallas Makerspace is unique as it’s the largest user funded and volunteer run makerspace in the U.S.

There are times when on the road you run into folks you have met before and this time was no exception. While at the North Texas SOLIDWORKS User Group, I ran into Rick McDonald. Rick works at GL Automation in Dallas. He had been in the Boston area in August and attended the Boston Area North SOLIDWORKS User Group where we met. It was great to run into him again in Texas – the SOLIDWORKS user group community is everywhere!”

“When first planning this trip, group leader William Radigan informed me that the week of their October user group meeting would coincide with the Albuquerque International Balloon Festival. As my airplane descended into the area, I could see in the early morning horizon the balloons taking off– it was magnificent!

That evening I presented at the New Mexico SOLIDWORKS User Group. William Radigan, group leader, was great host that evening.

The evening was full of great content with two presentations on the agenda. After dinner, I presented on DriveWorksXpress and the DriveWorksXpress Training and Certification Program. After a short break, Dr. Reza Tabatabai from SOLIDWORKS presented on the different modules available in the SOLIDWORKS Simulation Suite.

At the end of the evening, William presented me with a Certificate of Appreciation. Thanks William, it was truly a pleasure to present at the New Mexico SOLIDWORKS User Group.”

“The last stop on my tour was in Chattanooga, Tennessee. Did you know that it is also home to the “Little Debbie” brand of baked goods and snack cakes? Well, the Chattanooga SOLIDWORKS User Group held their meeting at McKee Foods – the home of Little Debbie!

Nicole runs a great meeting and she encourages group members to take an active role in the meeting. She engages with them to work together to develop future agenda topics. Nicole’s leadership is strong and the members love her.

After dinner and opening remarks, Nicole introduced me to the group. Over the course of an hour, we worked through the steps to set up and run a ‘bracket weldment’ project in DriveWorksXpress. This exercise gives users a chance to see the simple steps to design automation inside DriveWorksXpress. We discussed the new DriveWorksXpress Training and Certification Program. Upon return from my trip, I’ve already seen one person from this group become certified. Congratulations!”

“Special thanks to Craig Gilbreath, Christie Buresh, William Radigan and Nicole Walden. This was a great week spent on the road and I really enjoyed visiting your groups.

We look forward to seeing you all again at SOLIDWORKS World 2018 in LA! – Heather”

During the SWUGLe event at SOLIDWORKS World 2017, we announced our second annual DriveWorks award for the SOLIDWORKS Group Leader of the Year. The winner was Jeff Holliday, the Mid-Atlantic Region Independant SOLIDWORKS User Group leader.

Jeff accepted the “Activate to Automate” beer mat challenge and took it to the next level. Not only did he provide photos from his group holding the mats – he even used SOLIDWORKS to model a beer on a beer mat! Jeff’s submittals were awesome and they showed his dedication to running the user group as well as his passion for SOLIDWORKS.

The DriveWorksXpress Training and Certification is a free certification for all engineering and design professionals who have access to SOLIDWORKS.

The certification promotes learning and knowledge sharing in the SOLIDWORKS community. It’s endorsed by SOLIDWORKS EDU and it’s ready for you to share at your Q4 meetings!

Here’s what you need to do to qualify for the DriveWorks Award for SOLIDWORKS User Group Leader of the Year:

Become a CDWXA

It’s just 3 steps in 3 hours!

Complete step 1 and step 2 by visiting the DriveWorksXpress Training and Certification website. You’ll follow a tutorial where you’ll learn how to set up and run a DriveWorksXpress Project. Then you’ll make some changes to your project and take an online multiple choice test. When you pass, your certificate will be emailed to you. Don’t forget to tweet or email us a picture of you holding your certificate!

Spread the Word

Spread the word about the DriveWorksXpress Certification at your fall and winter user group meetings. Educate attendees using our awareness video and please send us a picture of them watching it. We’ll share it on our social media accounts.

Celebrate New Certified DriveWorksXpress Associates

We love to hear about the new Certified DriveWorksXpress Associates in your user groups and we want to help you celebrate their success. Send us photos of your CDWXA’s with their certificates and we’ll share them in our newsletter.

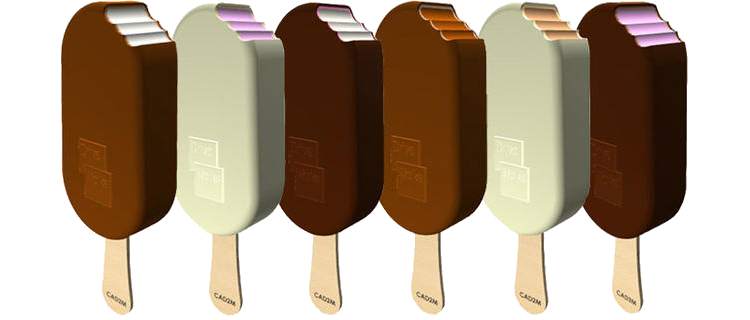

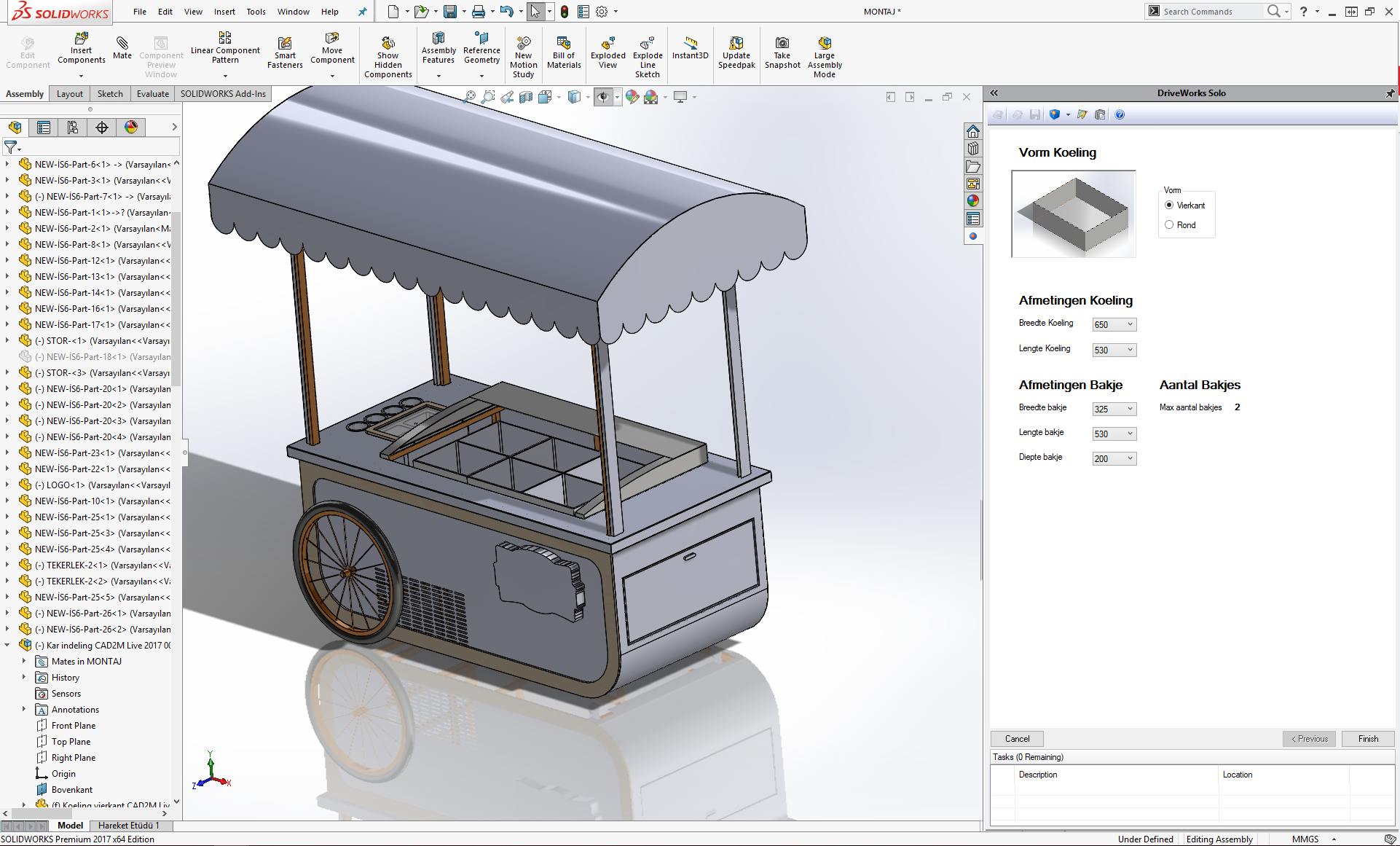

Back in August, we showed off an impressive Magnum configurator, created by CAD2M, a DriveWorks reseller based in The Netherlands. Now, CAD2M have taken the project even further with yet more creative ways to use DriveWorks.

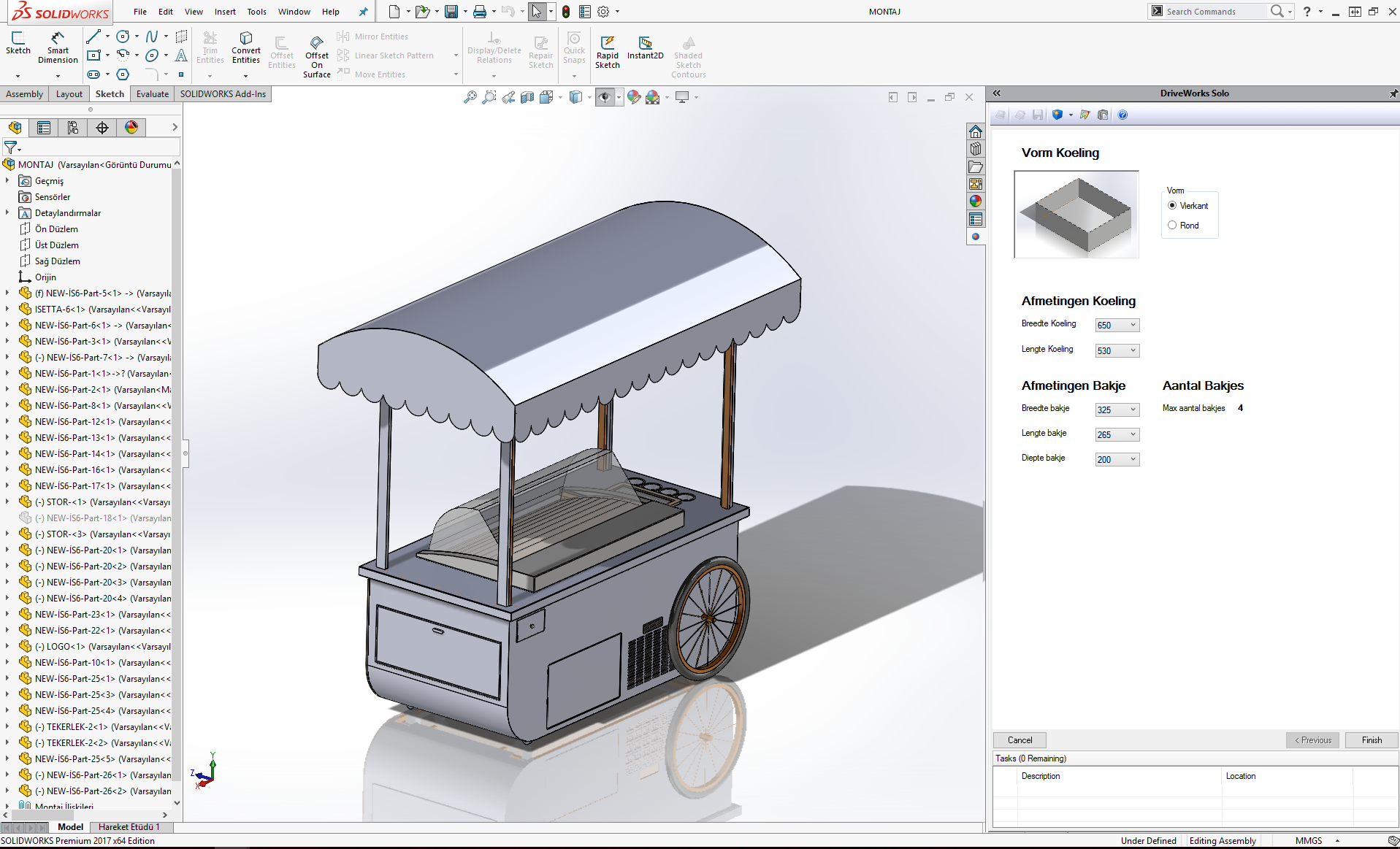

Our CEO, Glen and VP, Maria were at CAD2M Live last week where the team released the next phase of their ice cream configurator project. Maria presented at the event and following the presentation, CAD2M wheeled in some configurable ice cream carts, filled with ice cream!

SOLIDWORKS users gathered around the ice cream carts and the CAD2M team presented about DriveWorks and how the configurator project works.

Wendy from CAD2M, has been telling us more about the project:

“This summer we had launched a DriveWorks campaign, in which customers could configure their own Magnum.”

“This campaign was a great success, our customers seem to respond quite well to food! We were therefore thinking: what else can we do with ice creams?”

“From Magnums we shifted to Italian ice cream.”

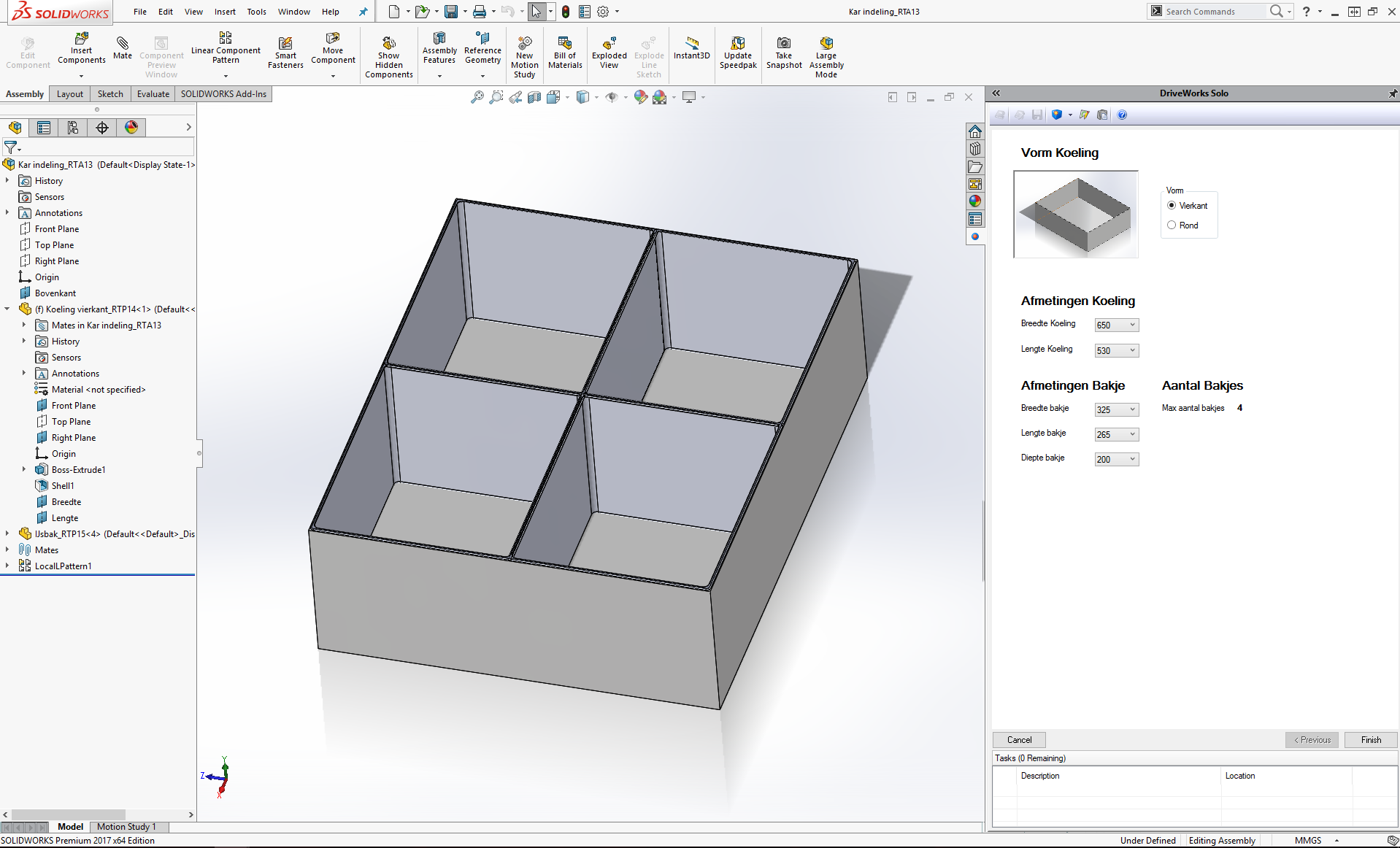

“To make the product a bit more practical, we decided to configure the cart that they’re scooped from.”

“The actual cart is completely different for every customer because the outside is what makes them unique.”

“The fridge and containers are about the same for everyone. Yes: about the same, because the dimensions and composition will vary. A perfect job for DriveWorks!“

“Our DriveWorks expert Carola made a project that starts with the fridge. After entering the fridges dimensions, we’ve got the base for our ice cream containers.”

“As everybody knows from their local ice cream store, some flavours are always very popular, but the less known flavours like pear and wasabi (yes, it does exist!) are hardly touched. Therefore, we need big and small containers in our cart, to take the right amount of the flavours with us.”

“With the configurator Carola designed, it’s possible to change the depth and width of the containers and assemble them together as desired.”

“The project was presented live at our customer day, CAD2M Live. And of course, we also had an ice cream cart present, including the ice creams! After our presentation, the audience was rewarded with this welcome treat. You’ll understand that there were a lot of interested visitors at our booth! As I said, our customers respond quite well to food!”

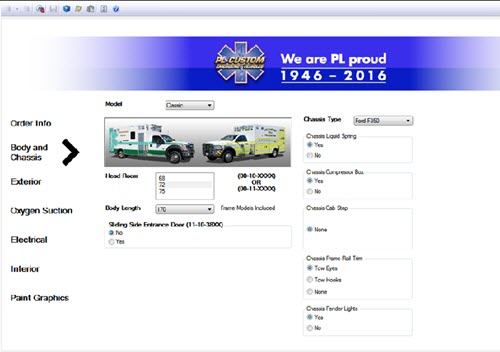

P L Custom Body are a custom vehicle manufacturer that were founded in 1946 and are based in Manasquan, New Jersey.

They make type 1 and type 3 ambulances, as well as custom rescue trucks. They have approximately 185 members of staff, 97 of whom work in production, 26 in sales and the rest are engineers, admin and internal sales. They have 17 dealers who cover 29 states and 1 dealer covering parts of Canada.

They’ve been using DriveWorks Pro to automate the configuration process of their custom ambulances. At DriveWorks World 2017, their Engineering Lead, Shawn Casebolt, took the stage to tell us more about how they use DriveWorks.

“When telling people what I do, one of their first questions is always ‘are ambulances different?’. The answer is yes they are the same…but different. This is why DriveWorks was such a good fit.”

“The pictures show just a couple of the light configurations on the front body of some trucks currently in production. We have hundreds of standard options available, but custom work is a whole other subject.”

“Approximately 2—3 years ago, we were tasked with getting our designs fully into SOLIDWORKS. We knew that we wanted our engineers to focus on the custom aspects of the design and not the configurable options, so we purchased DriveWorks and began implementation.” says Shawn.

“We started by laying out what we thought we wanted our model structure to consist of. This was then revised and it continues to be revised as we further develop it.”

“All part numbers are stagnant and are tagged with a job number. This allows departments such as sales, purchasing and manufacturing to always find what they’re looking for inside our SOLIDWORKS PDM system without having to browse. They can just search and DriveWorks has tagged the job number to the job specific parts so they’re easier to find.”

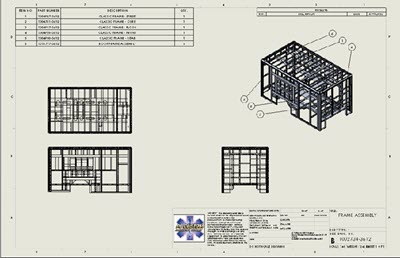

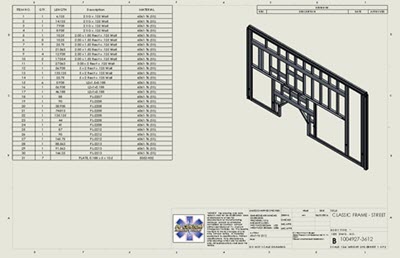

“We decided that we’d pick our most popular model and begin with the basic exterior frame. Then we’d bring more models into the mix based upon their popularity. Once we achieved around 80% of our models (by sales) then we would move on to content.”

“DriveWorks configured the compartment sizes you see above, as well as the body length and height. These walls all have our custom proprietary extrusions that have been created as weldments in SOLIDWORKS.”

“The framing drawings and framing assemblies are created by DriveWorks and our purchasing team will always be looking to send the same numbers to the vendor for cutting to satisfy demand for this type of vehicle.”

“Once we had all of our truck models with framing, we moved on to adding the exterior skins and we used DriveWorks to drive our most popular lighting selections and combinations. Once all of our chassis models were at this level, we moved on to the next phase of the project.”

“Even small parts, such as door trims, have their own assembly and drawing. But this is simple as DriveWorks is consistent with numbering and allows us to drive the lengths based on door heights. Compartments, like most other items, also have their own sub assembly. These fit into the door openings that DriveWorks is generating in the frames.”

“This is a screenshot of the DriveWorks form where our engineers input their options. Some options will give them a visual preview of the model, either through an image or by showing them the model. They complete the form based on the contract or specifications for the vehicle and DriveWorks then creates the full assembly structure.”

“In its current state, DriveWorks outputs 245 files, 60 of which are assemblies, 85 are drawings and the rest are parts files. With DriveWorks handling these repetitive tasks, our engineers are freed up to focus on the customized aspects of our designs—such as the internal cabinets of the vehicle.”

“Our primary focus is to increase our content level and our ability for interference detection and to drive purchasing. This will include adding the cots, attendant seats, doors and metal inserts for the cabinets. In the long term future, we will focus on the exterior of the vehicles and all lights, bumpers and other items.”

“We would like to eventually transition driving all purchasing from our models and being able to utilize DriveWorks for quoting projects.” Shawn Casebolt—Engineering Lead at P L Custom Body Inc.

Last week we blogged about our CEO, Glen, and Vice President, Maria, visiting the new Dassault Systèmes 3DEXPERIENCE lab in Waltham.

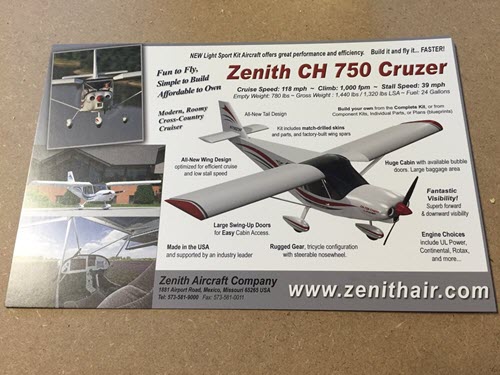

They saw plenty of cool projects and machinery, including a Zenith CH 750 cruzer aircraft kit that was being assembled by SOLIDWORKS engineers and professionals.

When the 3DEXPERIENCE Lab opened it’s doors, SOLIDWORKS employees, under Zenith Aircraft guidance, began the process of building this impressive aircraft in their FabLab. After only a few hours they had the rear fuselage assembly together.

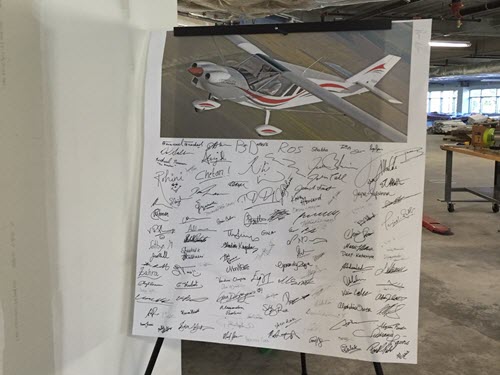

The project is ongoing and members of the SOLIDWORKS Community are working hard to complete the aircraft.

Maria and Glen were really impressed with the project and wanted to help in any way they could. Glen got stuck in and used a pneumatic riveter to add rivets to one of the wings. He also used a hand held rivet tool to add some the old fashioned way, which was harder than it looked!

This project is a great way to bring members of the SOLIDWORKS community together to build something impressive. It was nice to see how many people have signed the sheet to show their involvement and we’re happy to have been a part of it.

We’re excited to see the finished aircraft!

In May, Dassault Systèmes opened a new 3DEXPERIENCE Lab in Waltham, an open innovation laboratory and startup accelerator.

The laboratory is designed to nurture and empower disruptive projects, to allow innovation for a more sustainable world. The lab hopes to foster entrepreneurship and bring new experiences to life, whilst strengthening society’s future of creation.

The grand opening gave members of the Dassault community the chance to have a look around the amazing new space and really see its full potential. Engineers, designers, academics and students toured the space and a had a go with some of the equipment it houses.

The DriveWorks team were really excited to see the fascinating projects to come from the 3DEXPERIENCE Lab and the impact it will have on the industry and society as a whole.

Last week our CEO, Glen, and Vice President, Maria, travelled to the USA to spend time at SOLIDWORKS HQ. Whilst they were there, Terry Mccabe, who is part of the SOLIDWORKS Partner team, kindly offered to show them around the new 3DEXPERIENCE lab.

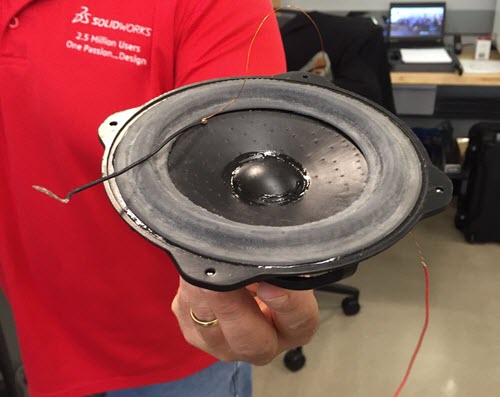

They got to see some really cool, innovative projects and one that really caught their eye was a 3D printed speaker. The 3D printing industry is growing and statistics show that it will be worth $13 billion in 2018. It’s amazing to see the types of intricate designs that these printers can produce and the speaker is a great example.

Terry also told them more about the impressive machinery in the lab, such as their ShopBot CNC Routing machine and their Tormach PCNC 440 milling machine.

When Maria and Glen returned to the office, they told us all about their visit and it really took us back to our roots. Glen loves to design and manufacture things, and the DriveWorks office is full of his wonderful creations, such as our new sound booth.

Innovation is something that the DriveWorks Team all share a passion for. This lead to us forming the DriveWorks Design club and visiting the FabLab in Manchester to manufacture a kiosk we’d designed.

The 3DEXPERIENCE Lab is a great facility and there’s so much potential for the future of design and the manufacturing industry. We’re excited to see what the future holds for the lab and we hope to visit it again soon.

We’ve been out on the road at a number of SOLIDWORKS 2018 Launch Events, chatting with SOLIDWORKS users about how they can work smarter and save time with design automation.

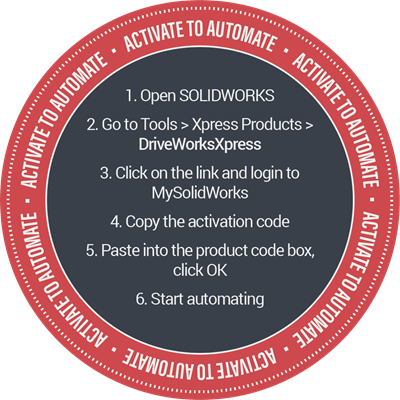

The best way for any SOLIDWORKS user to get started with design automation is to activate DriveWorksXpress.

DriveWorksXpress is our free design automation tool included in every license of SOLIDWORKS. DriveWorksXpress is installed and ready to use under the SOLIDWORKS tools menu. To get started automating your SOLIDWORKS designs, all you need to do is activate your free license.

If you see us at a SOLIDWORKS 2018 Launch Event come and grab one of our handy Activate to Automate beer mats.

DriveWorksXpress is a design automation tool, ideal for products that are the same but different.

Design automation with DriveWorksXpress is easy:

With DriveWorksXpress you will save time and reduce repetitive tasks whilst minimising errors and costly mistakes.

Learn more about DriveWorksXpress with our free online resources:

Maria and Glen from the DriveWorks team are attending CAD2M Live, which takes place on Thursday 12th October 2017 at the Midden Nederland Hallen in The Netherlands.

During the event, CAD2M will show you the latest features and functions in SOLIDWORKS 2018 and explain how to get the most out of the latest addition. Their experts will also show you how to work smarter, faster and more efficiently with SolidCAM.

The event will also focus on 3D printing and manufacturer If Adamas will give you a behind the scenes previous of the latest ‘dddrop model’ 3d printer.

Maria Sarkar, Vice President and Co-Founder of DriveWorks, will present to the audience and discuss how companies that use SOLIDWORKS to automate their design process could also use a DriveWorks CPQ Solution.

Maria is passionate about harnessing technology and marketing to deliver results and digital transformation. In her role, she travels the world visiting customer sites and working with resellers such as CAD2M. Join her to learn more about DriveWorks!

Check out the full agenda and register to secure your place at http://cad2mlive.nl/

We’re pleased to announce that SOLIDWORKS are gold sponsors of DriveWorks World 2018.

SOLIDWORKS have sponsored our annual user training event year on year and we can’t thank them enough for their on-going support.

We’re proud of our technology and the way so many customers use SOLIDWORKS and DriveWorks together to work smarter, seeing this all come together at our annual event is brilliant.

This year, we’re celebrating 10 years since SOLIDWORKS chose DriveWorksXpress as the design automation tool of choice for SOLIDWORKS, including our technology as standard in every license of SOLIDWORKS.

We’re thrilled that 10 years on, SOLIDWORKS still see the value in our technology and will be sponsoring, attending and presenting at our annual technical event!

To see what else we have in store for you at DriveWorks World 2018, and to secure your place, head to www.driveworksworld.com, see you there!

Our new library of Quick Tips videos quickly and clearly demonstrate a variety of features in DriveWorks.

Designed for users of all levels, everyone can find something useful in these videos. Whether you’re looking at what’s possible with DriveWorks, need a refresher on a feature you have not used in a while, or you are learning it for the first time, the Quick Tip videos take you through the process.

Each video is less than 90 seconds so you can get up to speed quickly, or pause after each step to learn at your own pace. There are also detailed descriptions for each video that explain each step.

There are currently 12 Quick Tips videos, we’ve listed them all below. If you have a suggestion for a Quick Tip video you would find useful, let us know!

Last week our CEO, Glen Smith and VP, Maria Sarkar, attended the Alignex MechFuse design and engineering summit in Minneapolis. The summit blended together new technologies, forward-thinking manufacturing strategies and educational sessions into one event.

MechFuse 2017 kicked off with some great keynote speakers who discussed new solutions and processes they’ve put into place that have taken their companies to the next level.

At lunch time, Glen and Maria hosted a 90 minute round table meeting where 30 attendees had the opportunity to ask questions and discuss what they’ve done / what they want to do using DriveWorks. The meeting was full and it was great to hear about all the cool things our customers are doing with DriveWorks!

Glen then presented to a full room and discussed how companies can automate to innovate and stay competitive using DriveWorks software.

This was followed by Matt Palumbo of Twin City Fans, a DriveWorks customer, presenting on how they have currently automated 80% of their products lines using DriveWorks and how the software benefits their company.

We also had a great booth in the partner area, where Glen and Maria spoke to many attendees about design automation.

Here’s a few snaps from our time at the event…