Last weekend Maria invited the DriveWorks Team to her house for our annual summer party. There’s always plenty of food, drinks, games and fun!

This year, the summer party fell on the same week as another very special occasion – our CEO, Glen Smith, turning 50!

The DriveWorks Team were joined by Glen’s family and friends, and together we celebrated Glen’s birthday in style.

Glen is a big fan of the Blues Brothers, so we set up our very own Blues Brothers themed photo booth – complete with blow up saxophones, guitars and sunglasses. There was a fantastic live singer, and later in the evening we listened to some of Glen’s music from when he used was in a band.

Our new placement students also joined us at the party and we really enjoyed getting to know them better and welcoming them to the team. Watch this space for an update about our new team members.

Thank you to Maria and Glen for hosting another fantastic summer party and….

We’re taking a break from our Tech Team Thursday webinars over summer. But we’ll be back in September with a great new series!

These webinars are our opportunity to share the Tech Team’s knowledge with our DriveWorks Pro Customers – with an Active Subscription Support Contract – and Reseller Applications Engineers.

In our latest series the DriveWorks Technical Team looked at some of the cool new features that were included in DriveWorks 15.

This is a great opportunity for you to catch up on any sessions you may have missed from our latest series by visiting the technical webinar library in the DriveWorks Community.

Here’s a few of the great titles from our latest series:

Don’t forget to join us on Thursday 7th September 2017 for the first webinar in our new series:

Integrating with 3rd Party Systems Using XML Data

In this article Adam Simons, of DriveWorks reseller CADimensions, discusses the benefits of using DriveWorks to U.S. based HVAC company, Zehnder-Rittling.

Jakob Zehnder first went into business in 1895 as a mechanic and bicycle dealer. The business evolved in the 1920’s, the Zehnder family began to successfully manufacture the Zehnder light motorcycle. It wasn’t until 1930 that they invented the product that would lay the foundation for the company’s future success: Europe’s first steel tube radiator.

The Rittling Corporation was founded by Charles Rittling in 1946. Their initial business was started by producing hydronic unit heaters in Buffalo, NY. As market demand in the U.S. changed, the company shifted its focus to commercial and residential heating needs that could be utilized with the new energy infrastructure developed in the 1940’s – 1950’s. Rittling was awarded its first US patent for twin tube residential baseboard elements in 1953. Hydro-Air Components acquired the Rittling Corporation and added Rittling Finned Tube to the product offering in 1979.

Zehnder Group acquired Hydro-Air Components and the brand conversion to Zehnder Rittling began in 2006. The acquisition enhanced Zehnder’s range of radiators and ceiling-mounted heating and cooling systems.

Since the acquisition 10 years ago, the Zehnder-Rittling company has continued to experience substantial growth in sales and products. They are keenly focused on being the most attractive provider of energy-efficient, healthy and comfortable indoor climate solutions. With over 30 products including hydronic heating, radiant heating and cooling, fan coils, and heat pumps. Zehnder-Rittling provides custom manufacturing capabilities to meet their customer’s requests. This is a challenge that most of their competitors are unable to match.

In order to maintain efficient engineering and manufacturing operations that support the volume of custom product requests, Zehnder-Rittling has looked for new ways to leverage their investment in SOLIDWORKS. By partnering with CADimensions, the company has transitioned their process from managing incoming orders with spreadsheets and generic drawings with “custom notes” to “built to order” custom models and drawings.

By implementing DriveWorks, they have been able to use data gathered during the sales process to automatically create models and drawings for each configured order. This step has enabled them to always provide accurate information to manufacturing, which has improved the quality of their products. Zehnder-Rittling has also leveraged their investment in PDM Professional to manage all of this newly created data and improve their internal quality control and “engineering to manufacturing” release process. That investment has allowed them to improve lead times on product shipments by 50-80%.

Their next steps are to investigate opportunities with DriveWorks Autopilot and PDM API capabilities. We believe additional steps in the process can be eliminated by allowing data gathered in sales (using their own custom quoting application) to pass directly through DriveWorks without any data entry by engineering. Furthermore, automating the export of Bill of Materials data to their ERP application using PDM API can eliminate data entry from engineering after the product is released.

This would mean even more opportunities for Zehnder-Rittling to dedicate resources to new product development and continue growing their business.

Following the success of the 3DEXPERIENCE Lab in France, Dassault Systèmes have expanded the project to North America, opening a lab in Waltham, MA. Dassault Systèmes announced their plans at SOLIDWORKS World 2017 and in May this year, the lab opened its doors for the first time.

Dassault Systèmes opened their new 3DEXPERIENCE Lab in May, an open innovation laboratory and startup accelerator.

The laboratory is designed to nurture and empower disruptive projects, to allow innovation for a more sustainable world. The lab hopes to foster entrepreneurship and bring new experiences to life, whilst strengthening society’s future of creation.

On announcing their plans for the lab at SOLIDWORKS World 2017, Dassault Systèmes said:

“Entrepreneurs, makers and innovators everywhere are invited to join our 3DEXPERIENCE Lab initiative. Our goal is to build a community of intelligent, creative and passionate people, focused on positively impacting society, through the creation of disruptive, groundbreaking projects. Dassault Systèmes is committed to helping them bring those projects to life, with the hopes of unleashing sustainable progress for tomorrow’s world.”

Not only will the lab bring creators together, it will also help startup companies. Startups will have access to the Dassault Systèmes´ 3DEXPERIENCE platform, including powerful tools like SOLIDWORKS and DriveWorksXpress, alongside invaluable resources, technical skills and mentoring. Being part of the Dassault Systèmes worldwide ecosystem will help accelerate the startups’ product launches and international presence.

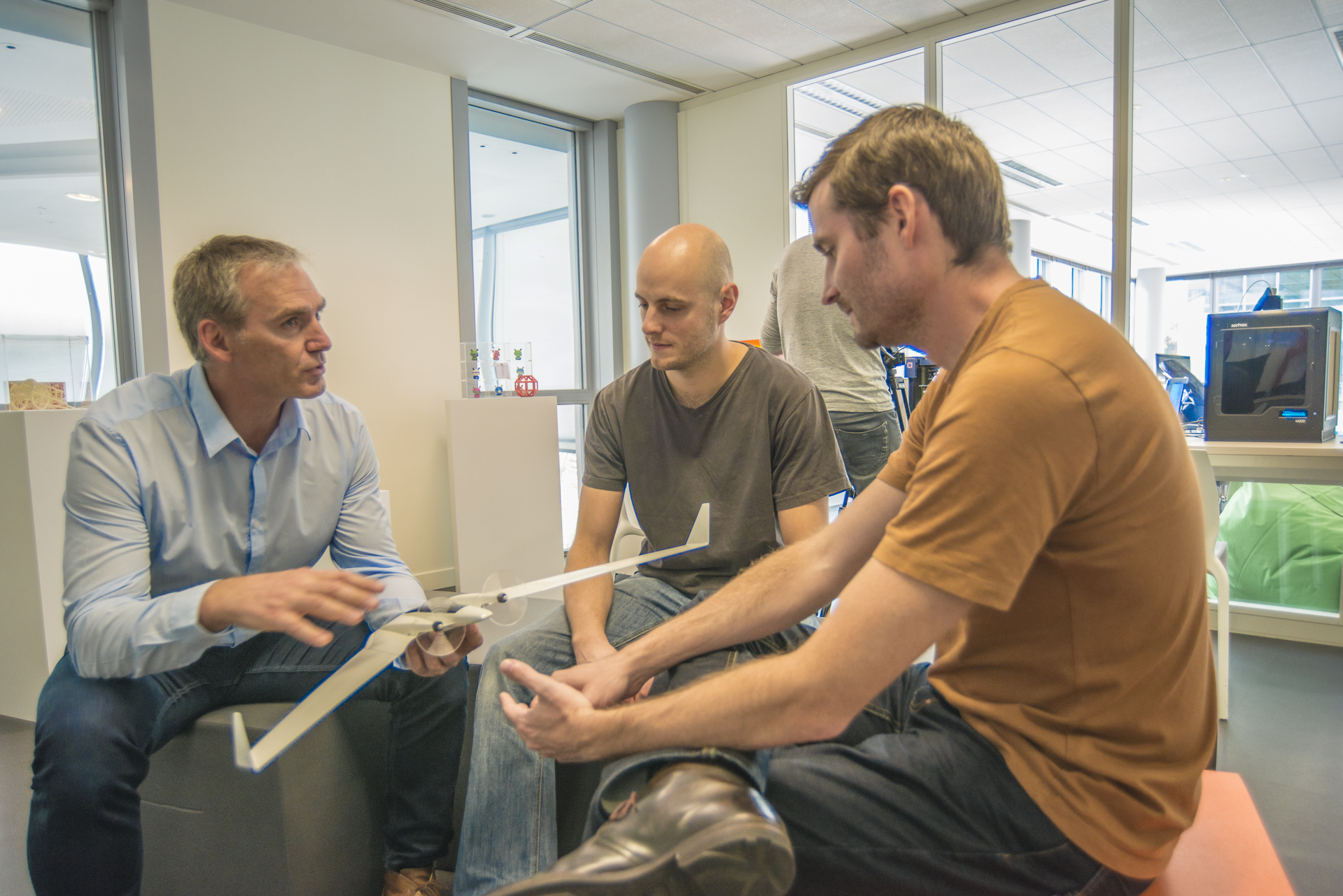

In collaboration with Massachusetts Institute of Technology’s Center for Bits and Atoms, the 3DEXPERIENCE Lab also has a digital fabrication space with state of the art tools, workbenches, 3D printers, laser engravers and a robotic arm. The Fab Lab space provides start ups with the tools they need to create product prototypes or refine their product ideas.

Since its opening in November 2015, the 3DEXPERIENCE Lab in France has seen successful projects in multiple industries. These include large-scale additive construction using robots, 3D printing of personalized organs for simulation of surgery, open source drones having capabilities of both a helicopter and an airplane, and upstream innovation by sketching in immersive virtual reality.

The 3DEXPERIENCE Lab is a really exciting addition to Waltham and will provide a great opportunity for startups, entrepreneurs, students and makers to excel, innovate and make a change in society.

The grand opening gave members of the Dassault community the chance to have a look around the amazing new space and really see its full potential. Engineers, designers, academics and students toured the space and a had a go with some of the equipment it houses.

As a SOLIDWORKS Gold Partner, we were really pleased to be invited to the event and Heather from the DriveWorks team went along to see the facility and equipment first hand and send some photos back for the rest of the team.

It’s clear what a great place the 3DEXPERIENCE Lab will be for everyone, but especially all of those involved in SOLIDWORKS Education and the SOLIDWORKS User Group Network.

We’re really excited to see the fascinating projects that are sure to come from the 3DEXPERIENCE Lab and what a great impact it will have on the industry and society as a whole.