DriveWorks – an easy to use CPQ solution that provides seamless links between customers, sales and engineering.

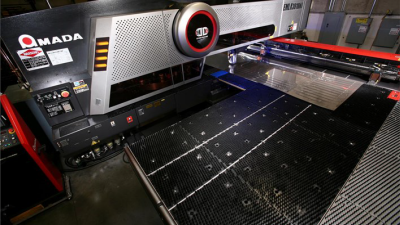

Are your distributors or customers asking you for prices online? How would they respond if they could configure orders themselves online? Would it help you stand out from the crowd if you could use 3D to visually show them what to expect?

Our new CPQ for Manufacturing demo site DriveWorksLive.com will give you a good idea of what you could accomplish using DriveWorks software.

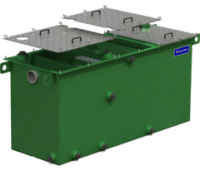

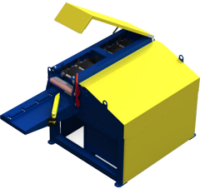

Configurable products are definitely the norm now in our personal lives. We’ve all seen, and probably used, the car or trainer configurators that so many recognized brands are using. Of course the business to business world, notably manufacturing, is now demanding this capability too.

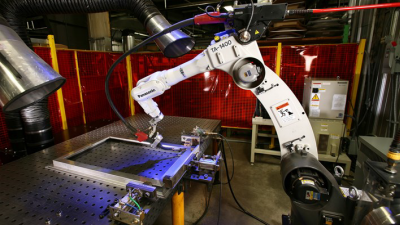

Engineers who use SOLIDWORKS 3D CAD software have been able to configure custom products using the DriveWorks add-on products for years. As the configurators are becoming mainstream, now sales teams want and need their own tools too. The good news is that DriveWorks software provides manufacturing companies with one collaborative solution, DriveWorks Pro, for both engineering and sales teams.

Product requirements can be entered online by anyone and at any stage in the sales to manufacturing process. As DriveWorks is a rule-based system, you can set up Team and User permissions, along with specific workflows, to keep your data safe and secure but highly accessible to those that you do want to interact with.

The examples on www.driveworkslive.com will give you a good feel for what is possible with DriveWorks. You’ll also see how our configurators are being applied across so many different industries.

If you visit the site be sure to enter your email address to receive various personalized quotes and documents – these are all sent automatically (again based on rules) via email, directly from the configurator.