Hi-Tech Outsourcing Services offer one stop solutions across various service lines and functions that include software, engineering and business processes. Many of their clients are in the US and Europe.

In order to join the DriveWorks Partner Program, Hi-Tech Outsourcing Services had to commit to and complete the DriveWorks Pro Training and Certification. They completed this during our recent visit to India, where members of the DriveWorks team met with their CEO and completed the training with their engineers.

Hi-Tech have been working with one of the leading window and door manufacturers in the US, to help them maximize their use of DriveWorks for design automation, product configuration and quote estimation.

The end result of implementing DriveWorks in this company’s design process is a reduction of engineering time required from 4-5 days to just 10 minutes. With design automation, Hi-Tech’s client has been able to respond to customer enquiries faster and provide accurate quotes. Customers can order their specific doors and frames, just in time and when they need it.

Ketan Panchal, Manager of Industrial Design Services, said that completing the training and certification was useful as it gave them more insight and knowledge about DriveWorks and obtaining the certification shows their capabilities with the different modules available.

We Asked Hi-Tech – What’s Your Favourite DriveWorks Feature and Why?

We love Customised Macro Features! The ability to program individual macros which perform varied and challenging automation tasks and integrate them into existing DriveWorks programs helps to expand programming flexibility to very large levels.

Another favourite of ours is Specification Flow as it helps us to integrate our business model right from receiving the raw material to dispatch/delivery of the finished product. This includes sales, engineering, accounts and shipments.

We also really like the user interface of DriveWorks Administrator. This is one of the most easy, convenient, self-explanatory and engaging tools we’ve seen. We like the ability to create different folders for every variable, customised user forms with the best look and feel, the ability to capture and define model rules and the rule builder tool.

We find these features are very useful for any business user and we truly believe that they distinguish and set DriveWorks apart from all other design automation tools.

On Wednesday 7th December 2016, DriveWorks were a proud sponsor of the SOLIDWORKS Largest User Group Meeting Ever (SLUGME).

This meeting was organised by SOLIDWORKS User Group of Nebraska group leader Todd Blacksher as he wanted to connect and share ideas with friends and colleagues ahead of the annual SOLIDWORKS World event. He teamed up with Central Massachusetts SOLIDWORKS User Group leader Tom Cote to host this event and Heather from the DriveWorks team was there to support them.

“What a great evening for everyone who was involved in this global event! User groups from as far away as Australia dialled in to take part and they all shared the same passion for design and also their commitment to supporting the SOLIDWORKS User Group Community.

Richard Doyle, SOLIDWORKS User Group Manager, tweeted out ahead of the event that there are 50 meetings on the SWUGN Calendar and 31 of them were happening that night at SLUGME.

SOLIDWORKS CEO, Gian Paolo Bassi, attended the meeting and gave welcoming remarks as well as congratulating the user group community on this great accomplishment. I believe that the total number of attendees was close to 740 and they estimate just under 200 pizzas were consumed – that’s a LOT of pizza!

As a proud sponsor of this event, we’d like to send our congratulations to both Todd Blacksher and Tom Cote for hosting a successful meeting!”

On Saturday November 19th, Maria, VP of DriveWorks team will be travelling to India with Chris, Mark and Tom from the DriveWorks team to host DriveWorks Training and Certification.

The team will be in India from 19th – 26th November and during their time they will be visiting some of our Value Added Resellers, Customers and our new Services Partner, Hi-Tech Outsourcing Services.

From Monday to Wednesday, Chris and Tom will be working through the DriveWorks Training and Certification in Bangalore. Maria and Mark will be visiting customers, completing sales training with our Resellers and meeting with the CEO of Hi-Tech Outsourcing Services.

On Wednesday evening the whole team will fly to Pune, where Chris and Tom will complete the Training and Certification with another group of Resellers. Maria and Mark will catch up with more customers and meet another representative from Hi-Tech OS.

This will be our first visit to India and we’re really excited, watch this space for a round up of our travels!

“We are really excited about the event in India. We want to show our commitment to our resellers, our existing customers and to the wider Indian SOLIDWORKS Community. Our goal is to provide DriveWorks Resellers in India with the opportunity to take DriveWorks training from our own DriveWorks Technical experts. We will also provide guidance on the benefits of using DriveWorks and how local resellers are best placed to support the software.“

“We will be visiting two locations – Pune and Bengaluru. This is a really good opportunity for everyone to increase their knowledge of DriveWorks and learn more about Automation and Configuration (CPQ for manufacturing) using DriveWorks”

– Maria Sarkar

Vice President DriveWorks

Register for the annual value added technical training event for DriveWorks Users, in Atlanta, USA from the 6th-10th March.

DriveWorks World is your chance to advance your knowledge of DriveWorks Pro Administrator and beyond. Talk to DriveWorks experts and learn from other users about the way they do things to improve the way you work.

Register now to secure your place and the early bird discount.

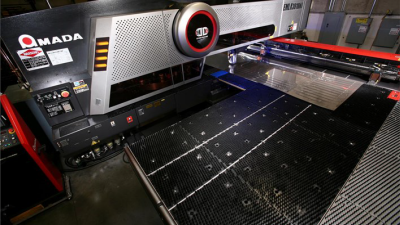

Blue Giant Equipment Corporation were founded in 1963 and initially specialised in the manufacture of dock levelers and hand pallet trucks.

Since then the company has grown rapidly with the addition of innovative technology, expanded product offerings and worldwide manufacturing and distribution facilities. Their renowned product line includes: dock levelers, ground-level lifts, vehicle restraints, intelligent dock controls and a diverse range of material handling products.

With over 8 million product combinations, Blue Giant were in need of a more simplified configuration solution.

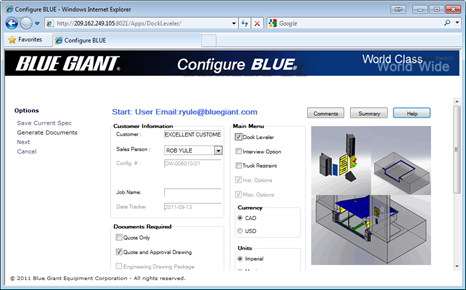

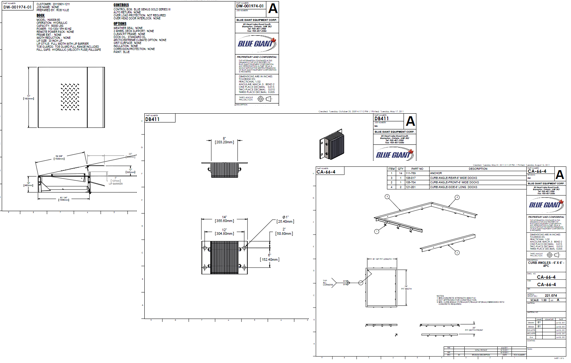

They now use DriveWorks Pro to power ConfigureBLUE™, their online parts configurator for use by their worldwide Authorised Dealers and Sales Teams.

The configurator is available 24 hours a day, 7 days a week and removes the confusion and learning curve often associated with configuring a solution from catalogues.

ConfigureBLUE™ is tied directly to Blue Giant’s internal manufacturing response planning (MRP) system and typically a quote will be received via email within seconds of configuring a solution.

By using DriveWorks, ConfigureBLUE™ generates 2D and 3D drawings and models to the customers exact specification and the drawing package is received within minutes of the request.

“We use DriveWorks for quoting and approval drawings for almost 160 teams and 530 users. We also use DriveWorks for production part component generation for various product lines and a whole bunch of other great stuff!” – Christopher Zona, Manager – Systems Automation.

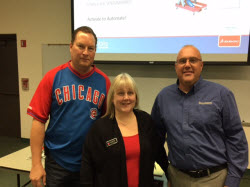

Members of the Blue Giant team regularly join us at our annual technical training event, DriveWorks World. Not only do they participate in our training sessions, they also present to other attendees and share their success.

Christopher Zona and Raymond Rosana of Blue Giant discussing their project with DriveWorks CEO, Glen Smith—DriveWorks World 2016.

“As we started planning the Fall SWUG tour of the Chicago area, no one could have predicted that for the first time in 70 years the Chicago Cubs would be competing for the World Series Championship of Baseball.

It’s been over 100 years since they have won a championship, so there is a fantastic electricity in the air that I felt as soon as I landed at O’Hare International Airport in Chicago on Tuesday afternoon.

A great and proud time to be from the Chicago area and everyone was showing their Cubs pride!”

“The Chicago SOLIDWORKS User Group met on Tuesday 25th October at Oakton Community college. While there may have been a baseball game on TV that evening, 20 people attended and we networked whilst eating Chicago style pizza.

Group leader Denny Bahl discussed the various SOLIDWORKS 2017 roll out events he had attended as well as the group meeting schedule for the next few months leading up to SOLIDWORKS World 2017.

It’s great when we have a chance to share who we are at DriveWorks and what we do. I presented about DriveWorks and DriveWorksXpress and it becomes much more than just showing folks how they can start to use the free design automation tool inside of SOLIDWORKS.

While the Chicago Cubs may have lost the opening game that evening, there were no losers in the room that night as they left after eating good food and having great discussions around the SOLIDWORKS Community.”

“The next morning I made my way to Aurora, Illinois to join the Chicago West SOLIDWORKS User Group who met at the Waubonsee Community College in Sugar Grove. This group is also lead by Denny Bahl – he leads TWO groups – what a dedicated guy!

We were a small group of about seven, but still had a very successful meeting. Getting my pizza fix for a second night in a row, we listened to the team from the Waubonsee Community College Workforce Development Group speak about the courses offered as well as local partnerships with employers that are working on connecting students with jobs, and vice versa.

Once again I had the privilege of speaking about the DriveWorks team and our products. Not only was the group engaged in discussion around DriveWorksXpress, but folks were taking a few of our ‘Activate to Automate’ beer mats back to their offices to share with others on their team!”

“As I reached the end of my DriveWorks Fall SWUG tour of Chicago I found myself in Rockford, Illinois. Thomas Clark, group leader of the Rockford Area SOLIDWORKS User Group, hosted me at Rock Valley College to present once again on DriveWorks and DriveWorksXpress.

This evening there were no baseball games being played and I was thrilled to have a full room of around 20-25 attendees. A full room is always great as there is a lot of information sharing and it’s just a great, busy space to be a part of.

The meeting was a great success and the presentation on DriveWorks and DriveWorksXpress was met with great interest and lots of questions. I came out of the meeting with none of the “Activate to Automate” beer mats that I brought with me on the trip. That’s always a good sign and I promised to send along a few more for the leader to give out to those that didn’t get one.”

As I sat in the airport on Friday morning awaiting my flight home the place was buzzing once again. People were arriving back into Chicago to watch the next baseball game of the World Series, making their way out on vacation and students were coming and going to and from college.

Goodbye Chicago! It’s been a great trip and I’ll be sure to see you again in the future…..so many user groups, so little time!

Meet the increasing demand for custom, bespoke and personalised products to gain a competitive edge. Generate quotes in record time, reduce the cost of custom designs and show off your configurable products in 3D, all with DriveWorks CPQ.

DriveWorks configurator software is the ultimate choice in 3D CPQ for manufacturing.

DriveWorks software is optimised for sales and engineering teams and has been rigorously tested and endorsed by real manufacturing companies, as well as by Microsoft and SOLIDWORKS as Gold Partners.

The ability to configure, price and quote easily has become essential for manufacturing companies of all sizes, in all industries. Customised products are becoming the norm. Transform the way you do business by closing the gap between initial sales inquiry and manufactured product with DriveWorks CPQ for manufacturing.

Break free from the constraints of conventional configurators. DriveWorks configurators look and work great on any device, allowing you and your customers to configure custom designs anywhere.

DriveWorks configurators are easy to set up with no programming skills or consultants required. Empower your sales teams, distributors and customers to configure complex custom designs quickly and easily.

Impress your customers from the start with an easy to use configurator and quick, accurate quotes and responses. Respond quicker and better than your competitors and win more orders.

Providing more than just CPQ, DriveWorks product configurators are based on rules, calculations and logic, improving the quality of outputs, reducing costly errors and strengthening your reputation.

Let your customers see their custom products in impressive 3D and view the effects of their design changes immediately.

Automatically send eye catching branded documents that are personalised to each customer and order.

Get started really quickly by customising our Sales Configurator and Catalogue templates with our intuitive Form Designer.

An easy to use workflow provides seamless links between teams as well as company systems such as CRM, ERP and CAD.

Reduce repetitive tasks by automating customer responses and repetitive engineering tasks.

Additional modules can be added as and when you need them to create a product configurator that suits your needs.

Try out one of the many configurator examples on DriveWorksLive.com.

Next week we’re on the road again, as Glen and Chris from the DriveWorks team will be joining DriveWorks Reseller, New Technology CADCAM, at a couple of their Great British Engineering Roadshow (GBER) events.

On Tuesday 1st November Glen will be in Sheffield and on Thursday 3rd November Chris will join NT CADCAM in Telford. They’ll be presenting about DriveWorks, our company and products.

These events are a great opportunity to find out more about SOLIDWORKS 2017, hear great speakers talking about engineering and manufacturing success stories galore and network with your peers. Register below to secure your place.

This release is a Service Pack that focuses on bug fixes and compatibility with SOLIDWORKS 2017. Make sure you head to the DriveWorks Community and download 14 SP 2 now.

As ever we have tested the updates rigorously across SOLIDWORKS and Windows Operating Systems (x32 and x64) to maintain reliability.

All DriveWorks Solo and Pro Customers with an active Subscription Support Contract and all Authorized DriveWorks Resellers can download the latest release now from the DriveWorks Community.

If you haven’t already, visit hub.driveworks.co.uk and create an account, you’ll then be able to download the new DriveWorks Service Pack.

The download should take no more than 30 minutes.

As with any upgrade, remember to take a back up of your data!

If you are working in a multi-user environment make sure you upgrade all of the DriveWorks Modules e.g. DriveWorks Administrator, Autopilot, any DriveWorks User licenses, DriveWorks Live AND of course DriveWorks Pro Server.

The DriveWorks online help files have been updated to give you all of the information you need to get started with this latest service pack.

As a SOLIDWORKS Gold Partner product, we’re really keen to get involved with the SOLIDWORKS community.

At the end of October Heather, who is involved in running the SWUGN Sponsorship program here at DriveWorks, is heading to Illinois to present at three SOLIDWORKS user group meetings.

At each meeting Heather will present about DriveWorks and DriveWorksXpress, showing attendees just how simple it is to “Activate to Automate” and save time in some of your same but different daily design work.

Attendees will also have the opportunity to network and refreshments will be provided. There will also be Q & A sessions and prize raffles!

When?

Tuesday 25th October 2016

Where?

Oakton Comunity College

Des Plaines Campus

1600 E. Golf Road

Des Plaines, Illinois 60016

When?

Wednesday 26th October 2016

Where?

Waubonsee Community College

Sugar Grove Campus

4S783 Illinois Rt. 47

Sugar Grove, Illinois 60554

When?

Thursday 27th October 2016

Where?

Rock Valley College

Woodward Technology Centre 1308

3301 N. Mulford Road

Rockford, Illinois 61114

Watch this space for more information about the events and don’t forget – if you’re a SWUGN leader and you need our help please get in touch!

DriveWorks World 2017 will be held at the Twelve Atlantic Station hotel in Atlanta, Georgia from the 6th-10th March 2017.

DriveWorks World is your chance to learn, network & share ideas with DriveWorks experts & enthusiasts. There will be something of interest and value to you, whether you are new to DriveWorks, or are an advanced user of the software.

Join us to be inspired and advance your knowledge.

Monday to Wednesday:

Track One: DriveWorks Pro Training & Certification

Track Two: Advanced DriveWorks Training & Workshops

Thursday:

DriveWorks World including:

Tailor your DriveWorks World experience by choosing which track you will follow from Monday to Wednesday. On Thursday, both tracks will join together for the main DriveWorks World event.

Track One

Ideal if you are quite new to DriveWorks, need a refresher or are working towards your DriveWorks Pro Certification.

Track Two

Ideal for experienced users and if you have already completed your DriveWorks Pro Certification.

DriveWorks World is open to all DriveWorks customers with an active Subscription Support Contract, Reseller Applications Engineers and DriveWorks Partners.

This week Heather from the DriveWorks Team has been out and about attending several events where she was able to talk with both SOLIDWORKS and DriveWorks customers.

The first stop for Heather was Computer Aided Technology’s Design Innovation Summit on 4th October.

This very successful and well attended event hosted a full agenda including ‘What’s new in SOLIDWORKS 2017’. CATI Application Engineers also presented on everything from SOLIDWORKS Electrical to SOLIDWORKS Simulation to discussions around 3D Scanning and Rapid Prototyping.

DriveWorks was a proud sponsor of this event and we had a booth in the “Productivity Zone” where we were able to talk with SOLIDWORKS customers, existing DriveWorks customers and others interested in learning about our software.

On Wednesday 5th October Heather headed to the Western Massachusetts SOLIDWORKS User Group, held at Smith College in Northampton, Massachusetts with group leader John Matrishon.

For those who may not know John, he is one of the founding members of the Bacon Brotherhood at SOLIDWORKS World. While there was no bacon served at this meeting, it was well attended with a combination of students, teachers and local SOLIDWORKS users.

Jay Pinheiro, Sales Engineer at Fisher Unitech, started the evening with an engaging discussion and presentation about SOLIDWORKS Productivity Tools.

Heather then presented about DriveWorks and DriveWorksXpress, showing the attendees just how simple it is to “Activate to Automate” and save time in some of your same but different daily design work.

Closing out the evening group leader, John Matrishon, gave a small glimpse of a project that he is currently working on where he is designing a cigar box guitar. He also showed off a guitar made for him by Central Florida SWUG leader Casey Gorman.

Heather hit the road once again on Thursday evening to attend and present at the Rhode Island/Southern Massachusetts SOLIDWORKS User Group meeting, RISOMA, held at Sensata Technologies in Attleboro, Massachusetts.

The evening’s agenda was full of content ranging from Paul Parise discussing the “Secrets of the Universe, using SOLIDWORKS” to Heather presenting once again on how easy it is to “Activate to Automate” DriveWorksXpress inside of SOLIDWORKS.

Tom Cote closed the meeting with his own presentation discussing ‘The Implementation of a PDM System’.

This was a great meeting and there was also some really tasty food for the attendees who had the pleasure of dining on ‘as close as you can get to homemade’ Polish American food (pierogis, kielbasa and golabkis) provided by Patti’s Pierogi in Fall River, Massachusetts – they have been on the Food Network!

Thanks to Robert Wing, group leader, for having us sponsor and present at this meeting!

If you’re a SWUGN leader and you need our help, or if you’d like to contribute towards the monthly newsletter, please get in touch!

On Thursday 22nd September 2016, Maria and Heather from the DriveWorks team hit the road to present at the Boston Area North SOLIDWORKS User Group meeting in North Billerica, Massachusetts.

As many of you located in America may know, this particular evening brought with it the promise of a budding new third-string quarterback for the New England Patriots starting in his very first official football game!

Not only did the Patriots win that night but there were also at least 50 people in attendance for the BANSWUG meeting. Everyone had a great time learning about SOLIDWORKS Visualize with a presentation given by Chris Mowatt of CAPInc.

Attendees also learnt about how SOLIDWORKS users can ‘Activate to Automate’ their designs with DriveWorksXpress. Maria and Heather enjoyed speaking with attendees before and after the presentations and even had the chance to have a photo taken with the legendary Flat SWUGN himself.

“It’s always fun to present at SOLIDWORKS user group meetings, but there is something about presenting to a local group, such as BANSWUG, that makes it more near and dear to me. Thanks to Dan and Tom for having us there and I look forward to the next chance to visit with this group.” – Heather.

Heather will also be attending the Western Massachusetts SOLIDWORKS User Group on 5th October 2016 with none other than one of the founding members of the Bacon Brotherhood – John Matrishon.

Registration is now open so sign up in order to secure your place and look out for more information on our events page!

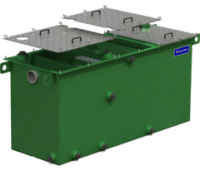

Industries Desjardins have been in business for 145 years and are well established in their region. They were originally dedicated to producing farming equipment however they have since expanded and now also manufacture fuel tanks, oil separators and sawmill machinery.

Every piece of equipment manufactured by Industries Desjardins can be customised to meet specific requirements. They’re also fully configurable using a range of equipment and accessories.

“Before we started using DriveWorks every sale needed countless hours of input from specialised technicians to import and modify CAD models and prepare the production drawings. It was time consuming so we needed to find a way to streamline the process.” – Serge Fournier—Design Project Manager.

“DriveWorks provided the tools to keep our staff focused on high value tasks while the software handles the easy stuff. DriveWorks has helped to cut approximately 85% off the drawing time on an average project.

Our library of CAD models has decreased significantly and thus contributed to lower engineering maintenance time on our CAD database.

Merging our high volume products to DriveWorks helps us to keep our project lead time as low as possible while our staff are used more efficiently in other areas.”

“DriveWorks software was easy to learn and the interface is very user friendly. We worked with DriveWorks and our Value Added Reseller, SolidXperts, who both provided great support for us throughout the implementation process.”

Previous system: countless hours

With DriveWorks: 85% reduction on drawing time

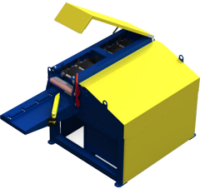

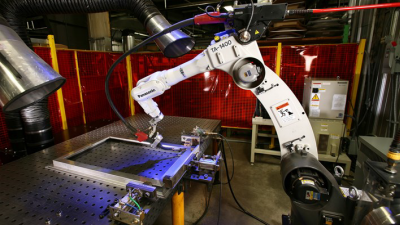

AJ Manufacturing is a lean, just-in-time manufacturer of some of the world’s best custom made commercial stainless steel HVAC products. They have a strong presence in the HVAC industry and continue to grow and diversify their product lines. Many of AJ Manufacturing’s products are featured in the world’s most successful hospitals, laboratories and commercial buildings today.

In 2004, Bob Haake, owner of AJ Manufacturing, wanted to incorporate new technology into their process. Later that year, they began using SOLIDWORKS in order to move their engineering and product design data away from 2D to 3D.

After realising the power of SOLIDWORKS, AJ Manufacturing began making smart models driven by design tables and equations. This significantly cut the engineering time associated with producing many of their custom, one off products that make them a unique supplier to the industry.

As their products and models became more complex, they began hitting the functional limits of SOLIDWORKS design tables and equations. Their search for a more powerful design automation solution for SOLIDWORKS led them to DriveWorks.

Now DriveWorks has been integrated throughout their entire product delivery process. Not only are many of their products being driven by DriveWorks, but DriveWorks itself has become a bridge between ERP, engineering and manufacturing.

By utilising many of the core functionalities of DriveWorks Autopilot, AJ Manufacturing’s process has evolved from several manual intervention steps to near full automation.

By using built-in DriveWorks connectors, they are able to drive and automatically create specifications by leveraging existing data created by the ERP system. Once the ‘build’ information is collected, DriveWorks Autopilot goes to work and begins to build new specifications.

Once DriveWorks Autopilot has completed the specification, a specialised DriveWorks plugin developed by AJ Manufacturing begins to dig through the assembly and collects the BOM information, such as:

– Part numbers

– Blank sizes

– Quantity

– Mass

After the plugin has interrogated the assembly or part, the information is then passed into a staging database table from which the ERP system can collect and leverage for reports and inventory control.

Once AJ Manufacturing’s projects are set up, functions that previously took a day or two to complete now take minutes using DriveWorks Autopilot.

Prior to using DriveWorks, their engineers spent many hours executing the minor tasks involved with custom products. These included renaming files, changing dimensional values, re-exporting manufacturing data and repairing file references from failed SOLIDWORKS Pack and Go functions.

“DriveWorks has saved AJ Manufacturing countless hours in production time alone.”

“AJ Manufacturing’s process, driven by the power and flexibility of DriveWorks, gives them a competitive advantage in bringing their customers higher quality, custom-made, just-in-time products, faster than anyone else in the industry.”

Are your distributors or customers asking you for prices online? How would they respond if they could configure orders themselves online? Would it help you stand out from the crowd if you could use 3D to visually show them what to expect?

Our new CPQ for Manufacturing demo site DriveWorksLive.com will give you a good idea of what you could accomplish using DriveWorks software.

Configurable products are definitely the norm now in our personal lives. We’ve all seen, and probably used, the car or trainer configurators that so many recognized brands are using. Of course the business to business world, notably manufacturing, is now demanding this capability too.

Engineers who use SOLIDWORKS 3D CAD software have been able to configure custom products using the DriveWorks add-on products for years. As the configurators are becoming mainstream, now sales teams want and need their own tools too. The good news is that DriveWorks software provides manufacturing companies with one collaborative solution, DriveWorks Pro, for both engineering and sales teams.

Product requirements can be entered online by anyone and at any stage in the sales to manufacturing process. As DriveWorks is a rule-based system, you can set up Team and User permissions, along with specific workflows, to keep your data safe and secure but highly accessible to those that you do want to interact with.

The examples on www.driveworkslive.com will give you a good feel for what is possible with DriveWorks. You’ll also see how our configurators are being applied across so many different industries.

If you visit the site be sure to enter your email address to receive various personalized quotes and documents – these are all sent automatically (again based on rules) via email, directly from the configurator.