Blog

Get the latest news, tips, events and software updates from the DriveWorks team.

-

How manufacturers are winning more deals with CPQ

CPQ is a highly effective tool for streamlining the custom manufacturing sales process. CPQ solutions guide sales teams through complex configuration and pricing and automatically generate accurate quotes. Delivering accurate custom quotes with quick turnaround times gives manufacturers the competitive edge to win more deals.

-

Busting The Myth: Design Automation is Taking Over Jobs

Design automation is designed to handle repetitive, time-consuming tasks, so engineers have more time to focus on higher-value work, such as product development and research. Design automation isn’t taking away jobs; it’s enhancing them. Find out more about how design engineers are using design automation to work smarter, producing more designs in less time, with improved accuracy.

-

IBR eliminate custom model errors with DriveWorks

IBR Redutores, based in Brazil, design and manufacture custom gearboxes and motors for machinery and equipment. IBR manufacture a range of product lines with multiple configurations. Using DriveWorks, they generate custom models and drawings with 100% accuracy and have reduced their custom CAD file generation time from 2 days to 10 minutes. Streamlining their design process has also enabled teams across the business to access models.

-

No Commitment, No risk: The Power of Software Free Trials

Free trials offer a valuable opportunity to explore new software and try out technology features. They enable you to test a product without any initial investment or commitment. With hands-on experience, you can evaluate performance, usability, compatibility with your business needs, integration features, and more, all at zero cost and zero risk.

-

AI in Manufacturing

AI is transforming how a wide range of industries operate, delivering smarter ways of working and improved efficiency. In manufacturing, AI technologies deliver multiple business benefits including reduced unplanned downtime, improved quality standards, and optimized design and production processes. The overall impact is an increase in operational efficiency and a reduction in business costs.

-

How DriveWorks Makes a Difference for Machinery Manufacturers

Custom machinery products are complex and time-intensive to design. Manufacturers must consistently meet custom specifications and quality standards so they can hit sales targets. DriveWorks design automation, 3D configurator, and CPQ solutions streamline design engineering workflows, ensure quality, and speed up the delivery of custom machinery products.

-

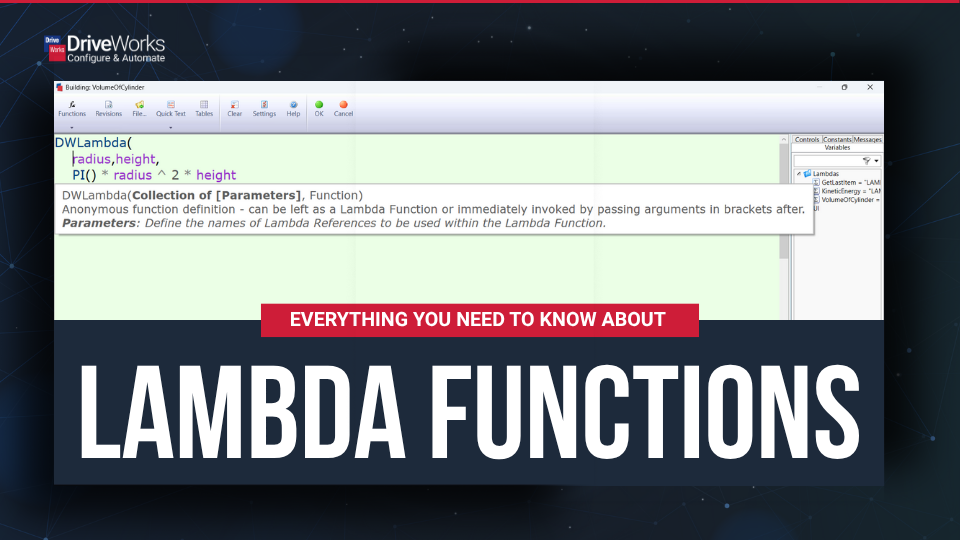

Everything You Need To Know About Lambdas

Lambda functions are a technique that was originally developed in the programming world. In DriveWorks, lambdas are a way to create custom functions to make your rules easier to read and understand without doing any coding. In this blog, we’ll explore how lambda functions work, when to use them, and how to get started with your own DriveWorks Lambdas.

-

Coming Up In July 2025

Get more from DriveWorks by joining one of our monthly webinars. They’re the ideal way to start exploring our technology or take your DriveWorks knowledge to the next level. Designed to introduce you to the benefits of our design automation, 3D product configurator, and CPQ for manufacturing solutions, each live session is hosted by a DriveWorks technical expert with the opportunity to ask your questions directly.

-

Design Minds Consulting Join the DriveWorks Partner Program

Although DriveWorks is easy to set up, maintain and use, sometimes companies just don’t have the time or right resources. Services Partners can assist with any aspect of setting up your DriveWorks project, injecting additional time and resources. We’re delighted to welcome Design Minds Consulting to our Authorized Services Partner Program.

-

International Women In Engineering Day 2025

With women making up just 17% of the UK’s engineering workforce, there’s a growing need to inspire more girls to explore STEM subjects at school and to encourage more women to consider engineering careers. On International Women in Engineering Day 2025, we take a look at the work that DriveWorks is doing to empower and support young minds, helping to nurture the next generation of engineers.

-

Reducing Costs with Design Automation

Manufacturers are looking for ways to deliver faster, cheaper, and better products, and one of the most effective ways of achieving this is with design automation. Design automation removes much of the manual work associated with traditional CAD workflows. By automating time-sensitive and repetitive upfront activities, manufacturers produce more designs, in less time, reduce bottlenecks and errors, and significantly reduce their costs.

-

Start your DriveWorks Solo 30-Day Free Trial Today

Free trials are an excellent way to explore new software and get hands-on experience with the technology. With a 30-day free trial you can quickly start to use DriveWorks Solo to automate your SOLIDWORKS designs, save time, reduce errors, improve quality, and streamline processes. Start your free trial today and get instant access to DriveWorks Solo, including certification and a wide range of technical resources.

-

DriveWorks World 2026 – Save the Date

DriveWorks World is the annual technical learning event for DriveWorks users and resellers. DriveWorks World 2026 will be hosted virtually from 14-16th April 2026. Registration is free for all DriveWorks customers with active subscription, resellers and authorized DriveWorks partners. Save the date and register your interest today to be the first to hear when registration officially opens.

-

June 2025 DriveWorks Drivers Meeting Round Up

DriveWorks Drivers connects DriveWorks users from around the world, featuring guest speakers sharing their experiences and encouraging questions and dialogue about the technology. Last week, we hosted our June meeting and were joined by over 100 attendees across two meeting times. Find out what we covered in the meeting and register to join us for the next DriveWorks Drivers in September.

-

DriveWorks in India

India is an important market for innovation, digital transformation, and technological adoption, and is rapidly embracing design automation technology in manufacturing, engineering, and construction. In recognition of this, we are continuing to develop strong partnerships in the region, ensuring that as many businesses as possible can benefit from DriveWorks technology. Learn more about DriveWorks in India.